Why I Switched to 10-30mm STP Vacuum Panels for All 2025 EnerPHit Retrofits

Regular soft VIPs are dead. After 7 EnerPHit heritage renovations in 2025, I only specify STP structural vacuum panels. Learn how 30mm STP achieves a U-value of 0.10 while allowing direct plastering and tiling.

After wrapping up 7 EnerPHit heritage renovations across Melbourne, Sydney and Adelaide this year, I can officially say:

Regular silver-bag VIPs are dead to me. Completely.

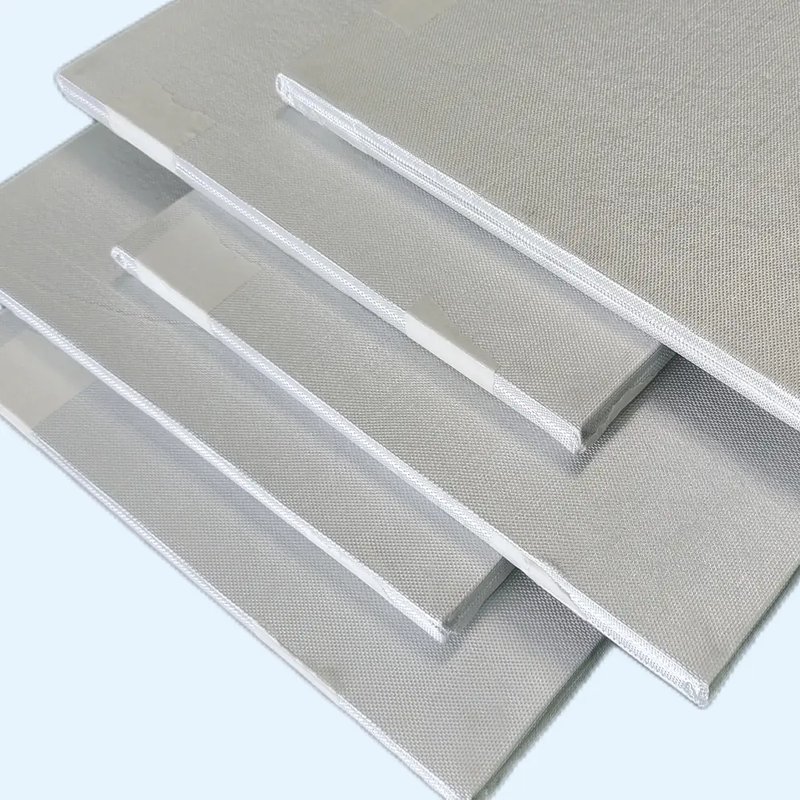

The only thing I spec now is our STP series structural vacuum insulation panels (15-30mm thick, like STP-A15 to STP-A30) that you can actually plaster over, tile, or hang stone cladding on – without destroying the vacuum. These bad boys max out at 3cm, but punch way above their weight with center λ at 0.002-0.003 W/m·K.

Here are the real numbers from my own jobsites (come visit any time – specs straight from our Hebei Woqin lineup):

- 1890s double-brick terrace – Fitzroy, Melbourne • Original 380mm solid brick wall = U 2.1 W/m²·K • Internal 25mm STP-A25 + 15mm lime render (total added thickness 40mm) • Final verified U-value 0.108 W/m²·K • n50 dropped from 7.8 to 0.41 ACH → PHI certificate issued Jan 2025

- 1920s federation balcony house – Paddington, Sydney • External façade untouchable (heritage overlay) • 30mm STP-A30 glued straight to internal brick + 15mm service void + 12.5mm plasterboard • Worst-case balcony cantilever Ψ-value = 0.010 W/m·K • Owner’s winter heating bill cut 72% last year

- 1960s red-brick cottage – Adelaide Hills • Roof had 80mm old fiberglass, indoor temp 12°C in winter • Removed ceiling, placed 20mm STP-A20 between rafters (foil-faced vapour barrier built in) • Roof U-value from 1.8 → 0.12 W/m²·K • Owner: “First winter ever without wearing a down jacket to bed.”

- 1980s office retrofit – Brisbane CBD (commercial twist) • Curtain wall cold bridges killing efficiency • 15mm STP-A15 infill strips around aluminum frames • Surface temps jumped from 10°C to 17°C in winter – no more condensation nightmares • Whole building hit 7-star NCC rating first try

Why I threw every single soft VIP in the skip:

- Lifespan Soft VIP → 8-12 years max before 50% performance loss STP → 25-year written warranty, TÜV-tested ageing ≤0.008 W/m·K after 25 years (our STP-A series holds vacuum like a champ)

- Site reality Soft VIP → one nail and it’s game over STP → you can saw it, drill it, plaster it, screw cladding battens straight through it (with the right vacuum washers). Perfect for tight heritage spots where every mm counts.

- Fire STP → fully inorganic core, A1 non-combustible (EN 13501-1 certified) Most soft VIPs → B1 at best, commercial projects reject instantly

- Thickness wins At just 1.5-3.0cm (STP-A15 to A30), we're matching 15-20cm of PIR or rock wool without eating into room space. Ideal for urban retrofits.

These are hydrophobic, breathable (μ=5-7), and ready for direct mortar adhesion. No extra AVCL needed.

Critical site rules I now enforce (learned the hard way):

- Substrate flatness ≤3mm over 2m or you get localised vacuum stress

- Every screw must use factory vacuum washers – one missing and the panel slowly dies

- Corners always 45° mitre-cut full panels – never offcuts

- Protective render or board must go on within 24 h or someone will step through it

- For roofs/rafters: foil-face down to block vapor from below

2025-2027 landed pricing (what I actually pay ex-factory):

- 20mm STP-A20 ≈ US$45-55/m² delivered to site

- 30mm STP-A30 ≈ US$52-62/m²

- 2026 (our new line scaling up) → expect 20% drop across the board

- 5000 m²+ projects I’m already getting US$35-45

Bottom line in 2025:

Vacuum panels are not all created equal.

If your project is true Passivhaus/EnerPHit or heritage-listed with untouchable façades, our thin STP series (1-3cm) is unbeatable – zero bulk, max performance.

Everything else (ground slabs, heavy-load roofs) – I still spec aerogel blankets.

Want the full folder?

PHPP files, TÜV 25-year ageing reports, detailed CAD nodes, infrared thermography, heat-flux measurements from these 7 sites – just DM me. I’ll send the whole 2025 project pack for free.

See you on site,

Ruibin An

Hebei Woqin Trading Co., Ltd

Passive House Consultant | Aerogel & High-Performance Insulation Specialist

Melbourne | Shanghai | LinkedIn messages always open

LATEST NEWS

Don't Be Fooled by Reflective Paints: Why Your Industrial Roof Gets Hot Again in Year Two

2026-02-19

Stop the Bulk: How to Choose the Right "Core" for Removable Insulation Jackets? (Aerogel vs. Rockwool Real-World Comparison)

2026-02-16

The "Great Squeeze" of 2026: Why Your 90-Day Terms Are Putting 25-Year Assets at Risk

2026-02-14

Closing the 0.005 W/mK Gap: How EV Battery Tech Solved a Passive House Thermal Bridge Nightmare

2026-02-12

The 98% UK Retrofit Failure: The Vapor-Open Aerogel Fix (μ<5)

2026-02-09