InsulateWool's Vacuum Insulation Panels: A Game-Changer in Cold Chain Logistics

Published: 2025-08-05

| Updated: 2025-11-04

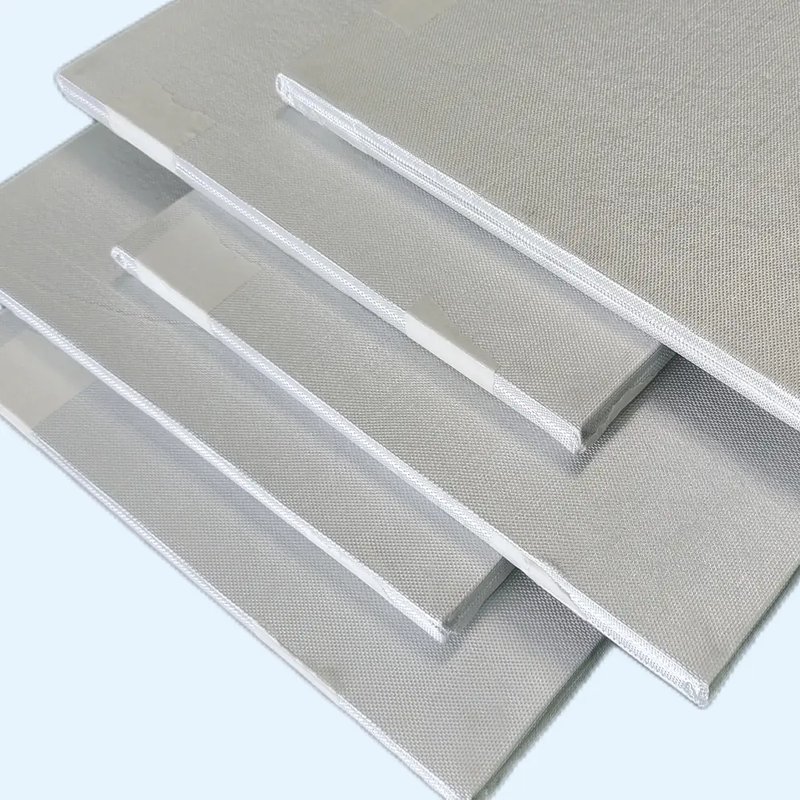

Vacuum Insulation Panel (VIP)

In the rapidly evolving field of cold chain logistics, InsulateWool's Vacuum Insulation Panels (VIP) are setting new standards for efficiency and sustainability.

In the rapidly evolving field of cold chain logistics, InsulateWool's Vacuum Insulation Panels (VIP) are setting new standards for efficiency and sustainability. As a leading vacuum insulated panels manufacturer, InsulateWool offers products that provide superior thermal insulation, boasting a thermal conductivity as low as 0.002W/(m·K). This remarkable performance surpasses traditional materials like rock wool and polyurethane, positioning InsulateWool at the forefront of the vacuum insulation panel market. The panels are not only lightweight and ultra-thin but also fireproof and environmentally friendly, making them ideal for a variety of applications, from urban building projects to industrial settings.

Table of contents:

Enhancing Cold Chain Efficiency with Vacuum Panel Insulation

The Science Behind Heat Insulation Material in Temperature Control

How Vacuum Insulation Panels Improve High-Temperature Equipment

Future Trends in Cold Chain Logistics with Vacuum Panel Insulation

Enhancing Cold Chain Efficiency with Vacuum Panel Insulation

Cold chain logistics relies heavily on maintaining precise temperature controls to ensure the quality and safety of perishable goods. InsulateWool's vacuum insulation panels are pivotal in enhancing this efficiency. By utilizing advanced materials such as silicon aerogel and a core vacuum chamber, these panels minimize heat transfer, thereby maintaining the desired temperature for extended periods. This capability is crucial for reducing energy consumption and operational costs, which are significant concerns in the vacuum insulation panel market. As a vacuum insulated panels manufacturer, InsulateWool is dedicated to providing solutions that not only meet but exceed industry standards, ensuring that products remain safe and viable throughout the supply chain.

The Science Behind Heat Insulation Material in Temperature Control

The science of heat insulation is at the core of InsulateWool's innovation. The panels incorporate a sophisticated combination of vacuum technology and industrial waste microsilica powder, contributing to their impressive thermal properties. This unique composition allows for a thickness range of just 3 to 15 mm, optimizing space without sacrificing performance. Such advancements are critical in the vacuum insulation panel market, where efficiency and sustainability are paramount. As a vacuum insulated panels manufacturer, InsulateWool has secured over 325 patents, underscoring its commitment to quality and technological advancement. These panels are designed to withstand harsh conditions, making them suitable for a wide array of applications, including high-temperature industrial environments and energy-efficient building renovations.

How Vacuum Insulation Panels Improve High-Temperature Equipment

InsulateWool's vacuum insulation panels play a vital role in enhancing the performance of high-temperature equipment. By significantly reducing heat loss, these panels help maintain operational efficiency and extend the lifespan of machinery. This is particularly important in industries where equipment is subjected to extreme temperatures, as it can lead to substantial energy savings and reduced maintenance costs. The panels' durability and fireproof nature make them an ideal choice for such demanding applications. As a prominent vacuum insulated panels manufacturer, InsulateWool continues to innovate, ensuring that its products remain at the cutting edge of technology and performance within the vacuum insulation panel market.

Future Trends in Cold Chain Logistics with Vacuum Panel Insulation

The future of cold chain logistics is poised for transformation with the integration of vacuum insulation panels. As demand for energy-efficient and environmentally friendly solutions grows, InsulateWool's panels are well-positioned to lead the charge. The trend towards sustainable practices is driving the vacuum insulation panel market, with an increasing emphasis on reducing carbon footprints and enhancing operational efficiencies. InsulateWool, as a forward-thinking vacuum insulated panels manufacturer, is actively participating in international standard formulations, ensuring that its products align with global sustainability goals. The potential for these panels to revolutionize cold chain logistics is immense, promising improved energy conservation and reduced environmental impact.

InsulateWool's Vacuum Insulation Panels are revolutionizing the cold chain logistics industry with their superior thermal performance and sustainable design. As a leading vacuum insulated panels manufacturer, InsulateWool is at the forefront of the vacuum insulation panel market, offering innovative solutions that enhance efficiency, reduce energy consumption, and support environmental sustainability. The panels' versatility and durability make them an ideal choice for a wide range of applications, from high-temperature equipment to urban building projects. As the industry continues to evolve, InsulateWool remains committed to driving innovation and setting new standards in thermal insulation technology.

Related Insulation Solutions

LATEST NEWS

Closing the 0.005 W/mK Gap: How EV Battery Tech Solved a Passive House Thermal Bridge Nightmare

2026-02-12

The 98% UK Retrofit Failure: The Vapor-Open Aerogel Fix (μ<5)

2026-02-09

10mm vs 150mm: The Truth About Guy Martin's Retrofit Challenge

2026-02-07

Respect the Physics: Hebei Woqin’s 2026 Unified Thermal Insulation Standard – Choose Right, Protect Long-Term

2026-02-06

If the Tang Dynasty Had VIPs: Why Modern Luxury Food Delivery Needs "Vaccine-Grade" Protection

2026-02-05