InsulateWool's Vacuum Insulation Panels: A Sustainable Choice for Builders

In the ever-evolving construction industry, sustainability has become a crucial focus.

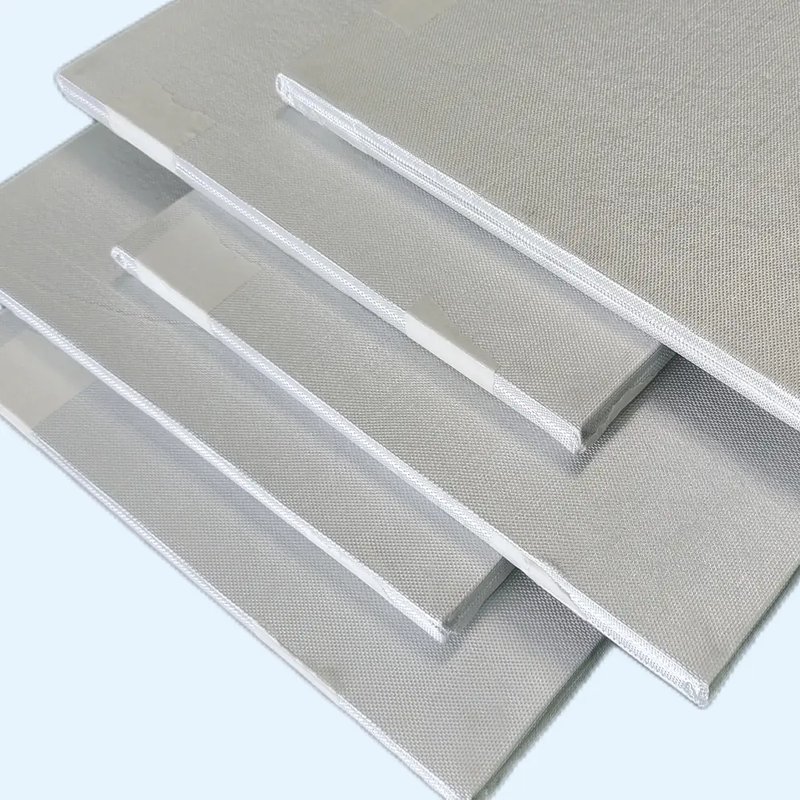

In the ever-evolving construction industry, sustainability has become a crucial focus. As builders strive to create eco-friendly structures, InsulateWool's Vacuum Insulation Panels (VIPs) emerge as a leading solution. Renowned for their superior thermal insulation, these panels boast a thermal conductivity as low as 0.002W/(m·K), outperforming traditional materials. As a prominent vacuum insulated panels manufacturer, InsulateWool offers products that are lightweight, ultra-thin, and durable, with thicknesses ranging from 3 to 15 mm. This makes them ideal for space optimization, especially in urban environments. The panels are not only fireproof and moisture-proof but also environmentally friendly, incorporating 70% industrial waste microsilica powder. With a service life of up to 60 years, these panels are a testament to longevity and sustainability in the building sector.

Table of contents:

The Environmental Benefits of Using Vacuum Panel Insulation

How Heat Insulation Material Contributes to Green Building Practices

Long-Lasting Performance: The 60-Year Service Life of InsulateWool's Panels

Innovative Building Solutions with Vacuum Insulation Panels

The Environmental Benefits of Using Vacuum Panel Insulation

The environmental impact of construction materials is a significant consideration for modern builders. InsulateWool's Vacuum Insulation Panels stand out in the vacuum insulation panel market due to their eco-friendly composition. By utilizing 70% industrial waste microsilica powder, these panels reduce the reliance on virgin materials and minimize waste. Their superior thermal insulation properties contribute to lower energy consumption in buildings, which is a crucial aspect of reducing carbon footprints. As a vacuum insulated panels manufacturer, InsulateWool ensures that their products not only meet but exceed environmental standards. The panels' fireproof and moisture-proof characteristics further enhance their sustainability, making them a preferred choice for builders committed to green building practices.

How Heat Insulation Material Contributes to Green Building Practices

Green building practices are essential for reducing the environmental impact of construction. InsulateWool's Vacuum Insulation Panels play a pivotal role in these practices by offering exceptional heat insulation. By significantly reducing energy consumption, these panels help in maintaining optimal indoor temperatures, minimizing the need for heating and cooling systems. This efficiency is crucial for achieving energy conservation goals in buildings. As a leading vacuum insulated panels manufacturer, InsulateWool provides solutions that align with sustainable construction standards. The panels' ability to enhance energy efficiency without expanding space makes them ideal for renovating older buildings, thereby contributing to the preservation of architectural heritage while promoting sustainability.

Long-Lasting Performance: The 60-Year Service Life of InsulateWool's Panels

Durability is a key factor in the selection of construction materials, and InsulateWool's Vacuum Insulation Panels excel in this regard. With a service life of up to 60 years, these panels offer long-term performance that is unmatched in the vacuum insulation panel market. This longevity not only ensures sustained thermal efficiency but also reduces the need for frequent replacements, thereby minimizing resource consumption. As a reputable vacuum insulated panels manufacturer, InsulateWool guarantees the quality and reliability of their products through rigorous testing and adherence to international standards. The panels' robust design, featuring a core vacuum chamber and silicon aerogel, ensures that they maintain their insulating properties throughout their lifespan, providing builders with a dependable and sustainable solution.

Innovative Building Solutions with Vacuum Insulation Panels

Innovation is at the heart of InsulateWool's approach to building solutions. Their Vacuum Insulation Panels are designed to meet the diverse needs of modern construction projects. By incorporating advanced technology such as a core vacuum chamber and silicon aerogel, these panels provide solid-state vacuum insulation that is both efficient and effective. As a leading vacuum insulated panels manufacturer, InsulateWool holds 325 patents, showcasing their commitment to innovation and quality. The versatility of these panels allows for their application in various environments, from building energy conservation to industrial thermal insulation and cold chain logistics. This adaptability makes them a valuable asset in the vacuum insulation panel market, offering builders cutting-edge solutions for sustainable construction.

InsulateWool's Vacuum Insulation Panels represent a significant advancement in sustainable building materials. As a prominent vacuum insulated panels manufacturer, InsulateWool is dedicated to providing products that not only meet the demands of the construction industry but also contribute to environmental preservation. With their exceptional thermal insulation, long service life, and innovative design, these panels are a sustainable choice for builders seeking to create eco-friendly structures. By reducing energy consumption and utilizing environmentally friendly materials, InsulateWool's panels play a vital role in promoting green building practices and ensuring a sustainable future for the construction industry.

LATEST NEWS

Closing the 0.005 W/mK Gap: How EV Battery Tech Solved a Passive House Thermal Bridge Nightmare

2026-02-12

The 98% UK Retrofit Failure: The Vapor-Open Aerogel Fix (μ<5)

2026-02-09

10mm vs 150mm: The Truth About Guy Martin's Retrofit Challenge

2026-02-07

Respect the Physics: Hebei Woqin’s 2026 Unified Thermal Insulation Standard – Choose Right, Protect Long-Term

2026-02-06

If the Tang Dynasty Had VIPs: Why Modern Luxury Food Delivery Needs "Vaccine-Grade" Protection

2026-02-05