2025 Vacuum Insulation Panels Real Review | Australia & Retrofit Projects

Published: 2025-08-13

| Updated: 2025-12-08

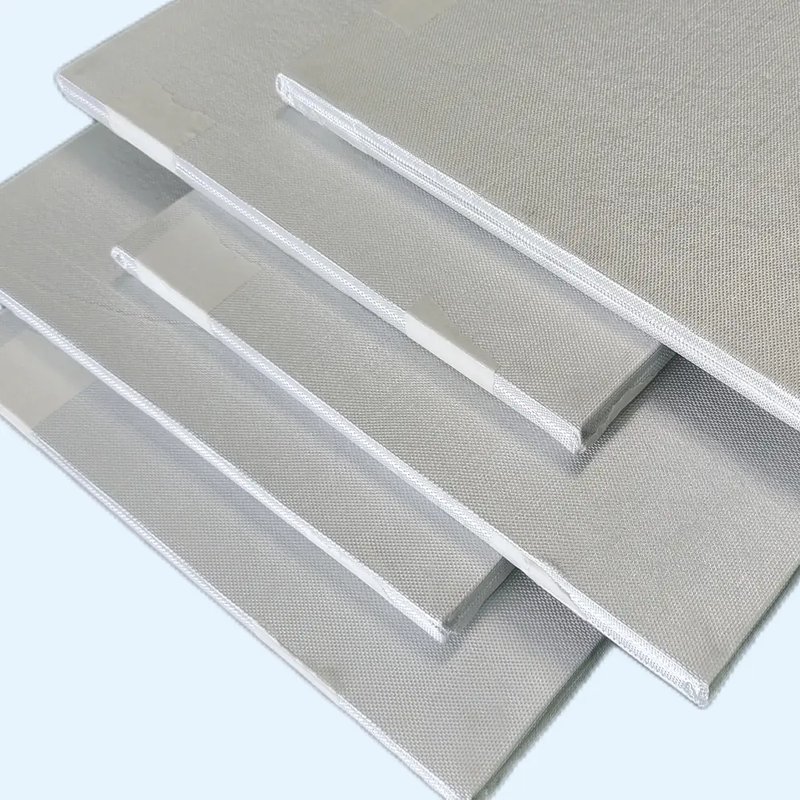

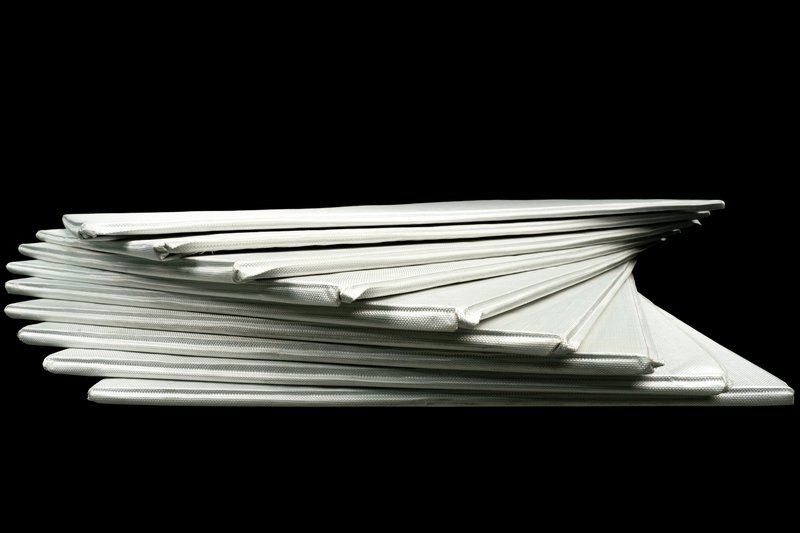

Vacuum Insulation Panel (VIP)

I’ve been selling and installing vacuum insulation panels across Australia and Europe since 2016. This is not another marketing page. This is what actually happens on real job sites in 2025.

2025 Vacuum Insulation Panels – The Stuff Sales Pages Won’t Tell You

I’ve been selling and installing vacuum insulation panels across Australia and Europe since 2016. This is not another marketing page. This is what actually happens on real job sites in 2025.

After cutting open a few thousand returned panels over the years, I can save you months of headaches.

Brand-new VIPs are insane – 0.002 W/m·K is real.

After fifteen or twenty years on a properly installed wall, the good ones are still around 0.007–0.008.

The bad ones jump to 0.025 the first time a tradie puts a screw through them or the edge seal fails.

Five years ago we threw out glass-fibre cores completely. Too many failures.

Today everything we ship is pressed fumed silica with proper getters and 3D-sealed edges that actually survive building sites.

Three jobs we finished in the last eighteen months:

Heritage terrace in Fitzroy, Melbourne – council said maximum 38 mm buildup on the external walls. We gave them 30 mm VIP + 8 mm aerogel blanket and got U-value 0.11. Owner’s winter bills dropped from AUD 1380 to under 440 a year.

Cold store extension south of Adelaide – swapped 150 mm PU for 35 mm VIP and freed up warehouse space worth well over a million dollars. Paid for itself in under four years.

The indigenous housing pilot in APY Lands, South Australia – the exact one Cameron Wilson at University of South Australia is writing up right now. 20 mm panels in light steel frames. Desert swings from minus 5 to plus 48. Inside temperature now varies less than 4 degrees in 24 hours instead of almost 20. We’re already talking about phase two in 2026.

Current 2025 factory-direct prices (minimum 500 m², larger orders cheaper)

Want to try before you commit? We send 1–2 m² free anywhere in the world. You only pay the courier.

One golden rule never changes: until both faces are fully protected, treat every panel like it’s made of glass. Do that and they’ll outlive the building. Treat them rough and they’ll let you down fast.

We learned all these lessons the expensive way so you don’t have to.

If you’re working on a passive house, a heritage retrofit, remote community buildings, or anywhere millimetres actually cost money – send me a message. I still answer my own phone and WeChat at stupid o’clock when someone’s stuck on site.

Ruibin An

Related Insulation Solutions

LATEST NEWS

Closing the 0.005 W/mK Gap: How EV Battery Tech Solved a Passive House Thermal Bridge Nightmare

2026-02-12

The 98% UK Retrofit Failure: The Vapor-Open Aerogel Fix (μ<5)

2026-02-09

10mm vs 150mm: The Truth About Guy Martin's Retrofit Challenge

2026-02-07

Respect the Physics: Hebei Woqin’s 2026 Unified Thermal Insulation Standard – Choose Right, Protect Long-Term

2026-02-06

If the Tang Dynasty Had VIPs: Why Modern Luxury Food Delivery Needs "Vaccine-Grade" Protection

2026-02-05