Vacuum Insulation Panel: The Safety Guardian and Energy-saving Pioneer in Future Life

Published: 2025-08-01

| Updated: 2025-11-04

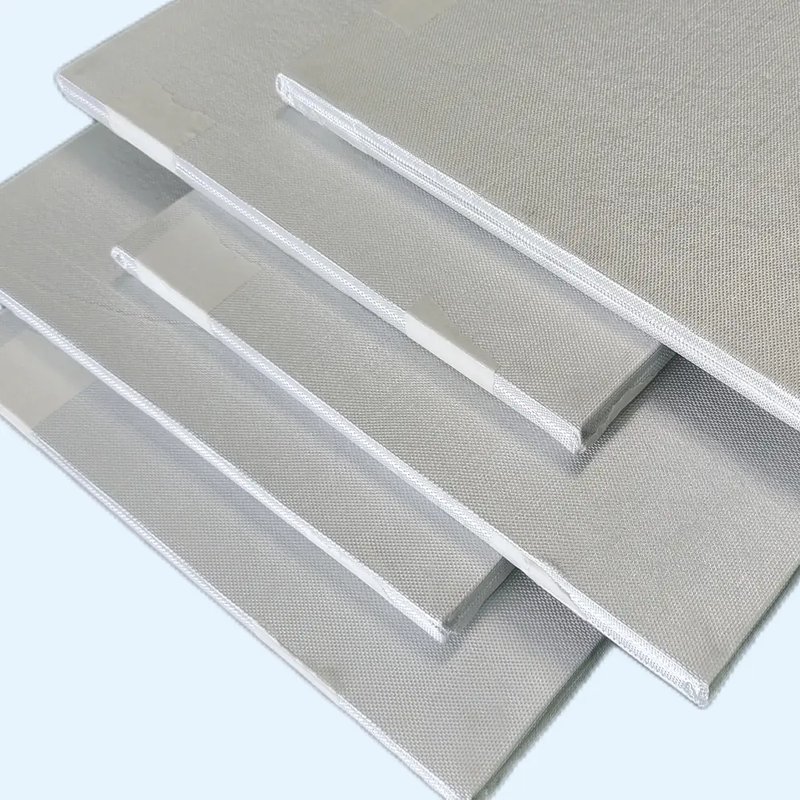

Vacuum Insulation Panel (VIP)

In modern society, the pursuit of energy conservation, emission reduction, and environmental protection is constantly increasing. Industries such as building energy conservation, cold chain logistics, and aerospace urgently need new types of thermal insulation materials to achieve the dual goals of efficient thermal insulation, energy conservation, and emission reduction. Among them, vacuum insulation panels, with their excellent thermal insulation performance, have gradually become an indispensable representative of innovative technology. It not only performs well in existing applications but also indicates broad prospects for widespread use in future life.

The Core Principles and Characteristics of Vacuum Insulation Panels

The structure of vacuum insulation panels mainly consists of a high - density rigid foam core and two layers of sealed metal or aluminum foil thermal reflection layers. The core part is evacuated to form a vacuum state, effectively blocking heat transfer, conduction, and radiation in the air, and greatly reducing heat flow transfer. Compared with traditional foam plastics or polyurethane insulation materials, the insulation performance of VIP almost reaches the ideal "insulation barrier" effect, with a thermal conductivity as low as 0.002 to 0.005 W/(m·K). This means that it can achieve a stronger insulation effect with an extremely thin thickness.

Not only that, vacuum insulation panels also have the characteristics of light weight, thin thickness, strong durability, and being less prone to deformation. In the construction field, this makes it a newer and more efficient energy - saving solution. Compared with traditional insulation materials, VIP has significant advantages in space - saving and design optimization, providing unlimited possibilities for high - end buildings and cold storage.

The Wide Application Fields of Vacuum Insulation Panels

With the continuous maturation of technology and the gradual reduction of costs, the application of vacuum insulation panels has begun to extend to multiple industries, demonstrating irreplaceable advantages:

1. Building Energy Conservation and Green Buildings

2. In modern high - rise and super - high - rise buildings, space utilization is of crucial importance. Traditional insulation materials often require a relatively thick number of layers to achieve the desired insulation effect, which limits the freedom of architectural design. However, the extremely thin design of VIP enables buildings to obtain a higher space utilization rate without sacrificing the insulation effect. At the same time, its excellent weather resistance and long - term reliability also reduce maintenance costs.

3. Cold Chain Logistics and Fresh Food Refrigeration

4. Cold chain logistics has extremely high requirements for maintaining the quality and safety of food and pharmaceuticals. The use of VIP in refrigerated vehicles, storage warehouses, and freezing equipment effectively avoids energy waste and ensures temperature control accuracy. At the same time, the insulation performance of VIP makes the refrigerated environment more stable, helping to extend the product shelf - life and reduce losses.

5. Aerospace and Military Applications

6. Under extreme environmental conditions, VIP provides an irreplaceable insulation solution. The cabins of aircraft, the insulation layers of spacecraft, etc., all rely on VIP to achieve efficient insulation and protect the safety of crew and equipment.

7. Electrical Appliances and High - end Consumer Goods

8. In high - energy technology equipment, ultra - clean environments, and cooling systems, the application of VIP significantly improves energy efficiency and safety. It can also be used in high - end household appliances to improve the insulation performance of products and extend the service life of equipment.

The Future Development Trends of Vacuum Insulation Panels

Continuous technological innovation promotes the performance improvement and cost optimization of VIP. In the future, with the progress of materials science, the thermal conductivity of VIP will continue to decrease, and its temperature resistance range and mechanical strength will also be enhanced, enabling it to work stably in more severe environments.

More importantly, with the implementation of green energy policies and the increasing demand for sustainable development, VIP will become one of the core elements of building energy conservation, making outstanding contributions to achieving the "green and low - carbon" goal. In the future, intelligent and modular vacuum insulation panels may be integrated into intelligent building systems to achieve synchronous optimization of temperature control.

Vacuum Insulation Panels - Guarding Our Safety and Improving Our Lives

It can be foreseen that vacuum insulation panels are gradually entering all aspects of our daily lives. Whether it is high - end buildings with strong insulation performance and space - saving features, or cold chain systems that ensure the safety of medicines and food, VIP plays an irreplaceable and crucial role. Its excellent performance is not only the product of technology but also the future of life.

Related Insulation Solutions

LATEST NEWS

Closing the 0.005 W/mK Gap: How EV Battery Tech Solved a Passive House Thermal Bridge Nightmare

2026-02-12

The 98% UK Retrofit Failure: The Vapor-Open Aerogel Fix (μ<5)

2026-02-09

10mm vs 150mm: The Truth About Guy Martin's Retrofit Challenge

2026-02-07

Respect the Physics: Hebei Woqin’s 2026 Unified Thermal Insulation Standard – Choose Right, Protect Long-Term

2026-02-06

If the Tang Dynasty Had VIPs: Why Modern Luxury Food Delivery Needs "Vaccine-Grade" Protection

2026-02-05