2025 Vacuum Insulation Panels (VIP/STP) – Real Factory Prices & Cold Chain Cases

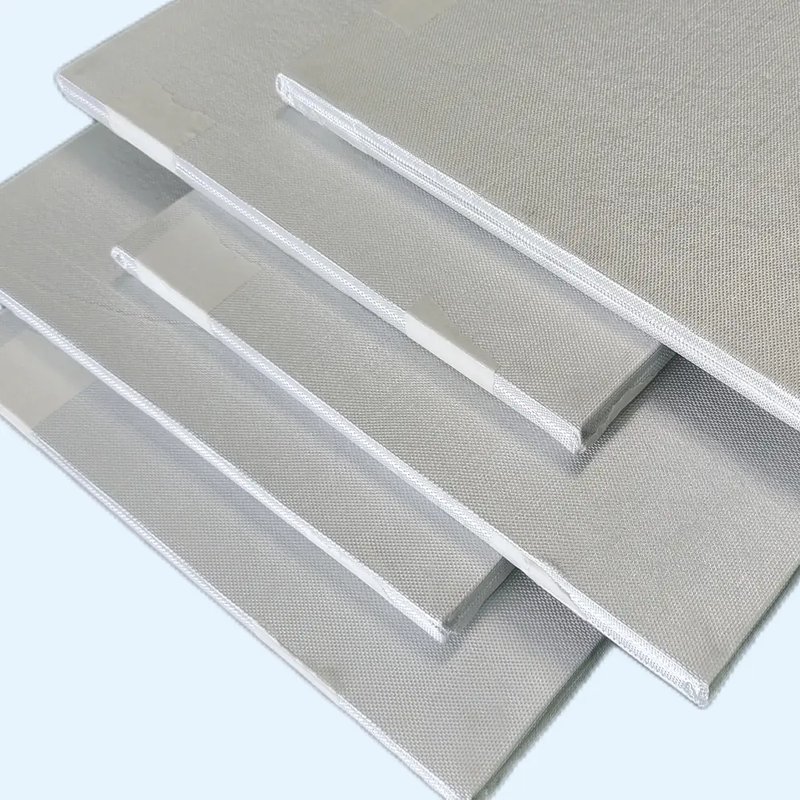

Stop wasting space with bulky PU foam. Learn how our 20mm fumed silica VIP panels achieve 0.0025 W/m·K conductivity. Real factory prices, durability data from 8-year-old projects, and global shipping info.

At Hebei Woqin (InsulateWool), we’ve been shipping VIP/STP panels since 2017. If you are looking for ultra-thin insulation for reefers, vaccine boxes, or cold rooms, this guide provides real-world performance data and 2025 factory pricing.

1. VIP/STP Technical Specifications

We focus on Fumed Silica and Fly-ash cores, having moved away from glass-fiber in 2020 due to durability issues.

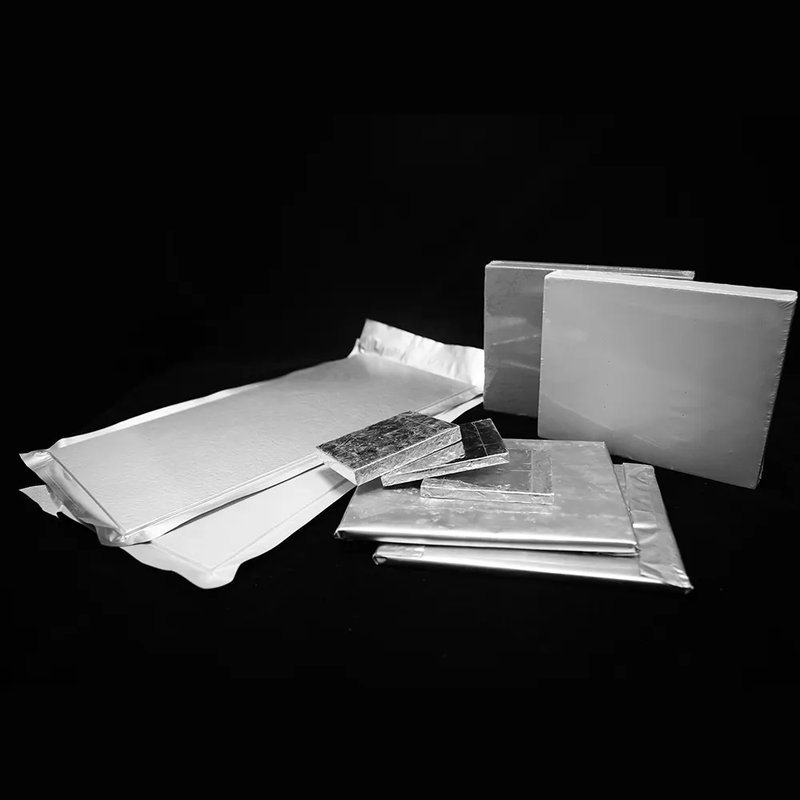

- Core Material: 95% Pressed Fumed Silica.

- Barrier Film: 7-9 Layer PET/AL/PA with nano-coating.

- Thermal Conductivity: 0.0025 - 0.0035 W/m·K (Fresh).

- Service Life: 15+ years with gas leakage <0.05 mbar/year.

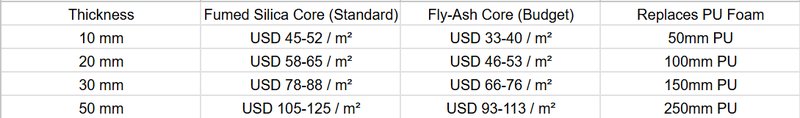

2. 2025 Factory Price List (FOB Tianjin)

Min. order 500 m². Prices vary based on core material choice.

3. Real Project Case Studies (Last 12 Months)

A. Vaccine Cold Boxes (Pharma)

- Solution: 25mm VIP + 5mm PCM.

- Result: Maintained -70°C for 168 hours without power. Weight reduced by 42% compared to PU insulation.

B. Reefer Truck Walls (Logistics)

- Solution: 20mm VIP + 10mm Aerogel Blanket combo.

- Result: 18% diesel savings on AC; temperature swings stabilized within ±0.8°C.

C. Seafood Cold Room (Storage)

- Solution: 30mm VIP panels on walls/ceilings.

- Result: Payback period under 3 years due to massive energy savings in a 2,000 m² room.

4. Important: The "No-Cutting" Rule

VIP panels work because of the vacuum. Never cut panels on-site. We provide a professional CAD-cut service to ensure exact fit with 10mm overlap flaps, ensuring zero "dead zones" in your insulation layer.

Get a Free Sample: We provide 1-2 m² samples worldwide. You only cover the DHL freight (approx. USD 150-250).

Contact Ruibin An at Hebei Woqin for a customized quote in 10 minutes.

LATEST NEWS

Don't Be Fooled by Reflective Paints: Why Your Industrial Roof Gets Hot Again in Year Two

2026-02-19

Stop the Bulk: How to Choose the Right "Core" for Removable Insulation Jackets? (Aerogel vs. Rockwool Real-World Comparison)

2026-02-16

The "Great Squeeze" of 2026: Why Your 90-Day Terms Are Putting 25-Year Assets at Risk

2026-02-14

Closing the 0.005 W/mK Gap: How EV Battery Tech Solved a Passive House Thermal Bridge Nightmare

2026-02-12

The 98% UK Retrofit Failure: The Vapor-Open Aerogel Fix (μ<5)

2026-02-09