Aerogel Felt: The Insulating Heart of Tomorrow’s Lightweight & Sustainable Structures

Modern lightweight architecture—tensile membranes, super tents, temporary pavilions, polar shelters—faces a common challenge: conventional insulation is thick, heavy, moisture-prone, and compromises light transmission or fire safety. Architects and engineers need a core material that delivers extreme thermal performance, durability, and design freedom without adding weight or complexity. Hebei Woqin’s aerogel felt is that material. As the exclusive high-performance aerogel felt supplier and technical collaborator for leading tensile membrane systems worldwide, we empower next-generation structures that are lighter, more translucent, more resilient, and profoundly sustainable. Key performance: Ultra-low thermal conductivity 0.015 W/(m·K) (−196°C to +650°C full range stability) Density 12–20 kg/m³ (1/10–1/20 of traditional materials) Hydrophobicity >98% (contact angle >150°) A1 fire rating (no melting, no toxic fumes per GB 8624-2012 / EN 13501-1 Class A1) Tensile strength ≥1.2 MPa, 80% compressibility with full recovery Typical application outcomes: 8 mm aerogel felt core integrated into advanced membrane structures delivers 5× thermal resistance, 60% lighting energy reduction, 15–20% natural light transmittance Wind load resistance up to 150 mph / 67 m/s (ASTM E330) Lancaster Shopping Center roof retrofit (25,000 ft², 72 hours, 40% energy savings, 30% more daylight) University of La Verne gymnasium (lighting energy −60%, enhanced natural illumination) Polar outposts and emergency shelters (−40°C to +50°C indoor stability ±2°C, 24-hour 500 m² assembly) Hebei Woqin: global leading aerogel felt supplier and technical partner, providing customized material solutions and collaborative design support to architects, membrane engineers, and project developers for lighter, brighter, tougher, greener buildings.

Aerogel Felt: The Insulating Heart of Tomorrow’s Lightweight & Sustainable Structures

Modern lightweight architecture—tensile membranes, super tents, temporary pavilions, polar shelters—faces a common challenge: conventional insulation is thick, heavy, moisture-prone, and compromises light transmission or fire safety. Architects and engineers need a core material that delivers extreme thermal performance, durability, and design freedom without adding weight or complexity.

Hebei Woqin’s aerogel felt is that material. As the exclusive high-performance aerogel felt supplier and technical collaborator for leading tensile membrane systems worldwide, we empower next-generation structures that are lighter, more translucent, more resilient, and profoundly sustainable.

I. Aerogel Felt: Pioneering a New Frontier in Materials Science

Aerogel felt is the insulating heart of tomorrow’s architecture. With an ultra-low thermal conductivity of 0.015 W/(m·K), it operates flawlessly from −196°C to +650°C, protecting against both polar cold and desert heat. Its nanoporous structure—a three-dimensional silica network with pores smaller than 70 nm—virtually eliminates gas convection, drastically reduces solid conduction, and effectively scatters thermal radiation.

Composited with glass or ceramic fibers, aerogel felt offers remarkable flexibility: it can be bent, cut, and shaped without losing integrity. Hydrophobicity exceeds 98% (contact angle >150°), repelling water like a lotus leaf and preventing moisture degradation that plagues conventional insulators. A1 fire resistance (no melting, no toxic fumes per GB 8624-2012 / EN 13501-1 Class A1) and density as low as 12–20 kg/m³ (core density, enabling ultra-light composite structures) make it extraordinarily lightweight yet durable. Surface modifications boost tensile strength to ≥1.2 MPa, ensuring long-term performance under tension and environmental stress.

II. Empowering Advanced Membrane Structures

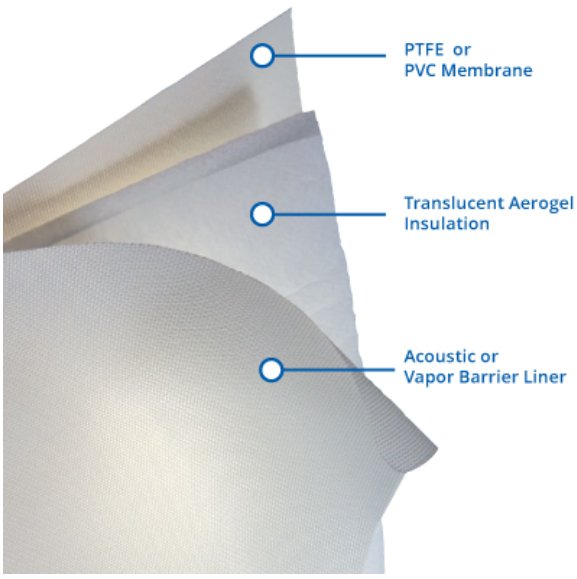

Leading tensile membrane systems integrate our aerogel felt as the critical insulating core, creating structures that combine beauty, performance, and resilience. The outer PTFE-coated fiberglass membrane provides 30+ year lifespan, 15–20% light transmittance for diffused daylight, and self-cleaning properties. An 8 mm aerogel felt insert multiplies thermal resistance fivefold, maintaining temperate interiors year-round without heavy HVAC reliance.

The inner liner achieves an NRC of 0.9 for acoustic comfort. Real-world example: projects featuring our aerogel felt, such as the Lancaster Shopping Center roof retrofit (25,000 ft² completed in 72 hours), achieved 40% energy savings, 30% more natural light, and wind resistance up to 120 mph at 1/20th the weight of steel alternatives—thanks to the aerogel felt core supplied by Hebei Woqin.

III. Thriving in Extreme Realms: From Arenas to Arctic Outposts

Aerogel felt excels where conventional materials fail. In projects such as the University of La Verne’s gymnasium, integrated aerogel felt slashed lighting energy 60%, delivering vibrant natural illumination in a large-span membrane structure. In extreme environments, it maintains indoor stability from −40°C Siberian cold to +50°C desert heat with variations under ±2°C—critical for occupant comfort and equipment reliability.

Rapid deployment is another strength: a 500 m² super tent can be assembled in 24 hours, ideal for disaster relief or military forward bases. Sustainability is built-in: fully recyclable components yield 70% lower lifecycle emissions than concrete equivalents, aligning with global net-zero goals. From Antarctic research stations to urban pop-up pavilions, aerogel felt proves architecture can be nomadic, enduring, and eco-conscious.

IV. Hebei Woqin: Your Partner in Architectural Innovation

Hebei Woqin Trading Co., Ltd. is the leading global supplier of high-performance aerogel felt for advanced membrane and lightweight structures. We collaborate closely with architects, membrane engineers, and system integrators to deliver customized solutions: material selection, thickness optimization, pre-forming, thermal modeling, and on-site integration guidance.

Our aerogel felt has powered projects ranging from high-end camping tents (cold resistance from −10°C to −30°C, condensation cut 50%) to LNG facility envelopes and polar research bases. LEED Platinum-certified applications demonstrate our commitment: from energy-harvesting facades to extreme-environment shelters, we enable designs that blend innovation with ecology.

V. Visionary Horizons: Aerogel Felt’s Role in the Future of Architecture

Aerogel felt heralds a renaissance in lightweight, sustainable construction: insulation that also contributes to acoustics, light diffusion, and structural efficiency. It requires 1/5th the production energy of traditional rivals, with full recyclability closing the loop on waste. Design freedom follows—vast clear spans, fluid curves, and modular mobility become possible, from pop-up event spaces to adaptive habitats.

As climate resilience becomes non-negotiable, aerogel felt enables harmony: technology in tune with nature, crafting spaces that protect, inspire, and endure. The future isn’t heavy and opaque—it’s tensioned, translucent, and aerogel-infused.

Take Action: Bring Aerogel Felt to Your Project

Whether you are an architect designing a tensile membrane structure, an engineer planning a lightweight pavilion, or a developer seeking sustainable solutions, Hebei Woqin offers the core aerogel felt and technical expertise to make your vision reality.

Contact us today to:

- Download the “Aerogel Felt for Lightweight & Sustainable Architecture Guide” (free).

- Request a tailored material specification and integration proposal for your project.

- Schedule a 20-minute consultation with our architectural materials specialists.

Hebei Woqin Trading Co., Ltd.

Phone/WhatsApp/WeChat: +86 139 3392 9092

Email:an@cn-aerogel.com

Website: insulatewool.com

We specialize in advanced aerogel felt solutions for 12 years. We partner with architects, engineers, and membrane specialists to deliver verifiable performance and true sustainability.

Written by - Zhongjian An

Certified Passive House Designer (PHI Germany), validated by Prof. Dr. Wolfgang Feist. With 15+ years of expertise in high-performance solutions for both Green Buildings and Industrial Applications (Petrochemical Pipelines, LNG Cryogenic, & High-Temp Equipment).

LATEST NEWS

Don't Be Fooled by Reflective Paints: Why Your Industrial Roof Gets Hot Again in Year Two

2026-02-19

Stop the Bulk: How to Choose the Right "Core" for Removable Insulation Jackets? (Aerogel vs. Rockwool Real-World Comparison)

2026-02-16

The "Great Squeeze" of 2026: Why Your 90-Day Terms Are Putting 25-Year Assets at Risk

2026-02-14

Closing the 0.005 W/mK Gap: How EV Battery Tech Solved a Passive House Thermal Bridge Nightmare

2026-02-12

The 98% UK Retrofit Failure: The Vapor-Open Aerogel Fix (μ<5)

2026-02-09