Architectural Aerogel Felt: The Insulating Heart Powering the Next Wave of Lightweight, Resilient Structures

As global demand surges for rapid-deployment, net-zero, and climate-resilient buildings—from polar research stations to desert pop-up venues—traditional insulation has become a critical bottleneck: thick, moisture-prone, light-blocking, and fire-vulnerable. Hebei Woqin’s high-performance aerogel felt is changing that reality. With ultra-low thermal conductivity of 0.015 W/(m·K), full-range stability from −196°C to +650°C, A1 non-combustible rating (GB 8624-2012 / EN 13501-1), superhydrophobicity >98% (contact angle >150°), and exceptional flexibility, it enables architects and membrane engineers to achieve extreme performance without sacrificing design freedom, natural light, or safety. As the exclusive core supplier for leading tensile membrane systems worldwide, we offer more than material—we deliver end-to-end technical partnership: thermal simulation, custom composites, system integration, and on-site guidance to turn visionary designs into verifiable, sustainable reality.

Architectural Aerogel Felt: The Insulating Heart Powering the Next Wave of Lightweight, Resilient Structures

To architects, membrane structure engineers, and project decision-makers:

In a world racing toward rapid-deployment, net-zero, and climate-resilient buildings—from Arctic research stations enduring −40°C blizzards to desert pop-up venues under 50°C scorchers—traditional insulation has become the silent compromise. Too thick to preserve elegant spans, too moisture-sensitive to survive humid or coastal exposure, too opaque to embrace natural light, and too flammable to meet modern safety demands.

What if the core of your next structure could eliminate those trade-offs entirely?

Hebei Woqin’s high-performance aerogel felt is that core. Engineered as the “insulating heart” for advanced tensile membrane systems, it delivers 0.015 W/(m·K) ultra-low thermal conductivity, full-range stability from −196°C to +650°C, A1 non-combustible rating (GB 8624-2012 / EN 13501-1), superhydrophobicity >98% (contact angle >150°), and exceptional flexibility—allowing you to design lighter, brighter, more resilient architecture without ever sacrificing performance.

Part 1: The Material Revolution – Why Aerogel Felt Is the Defining Core

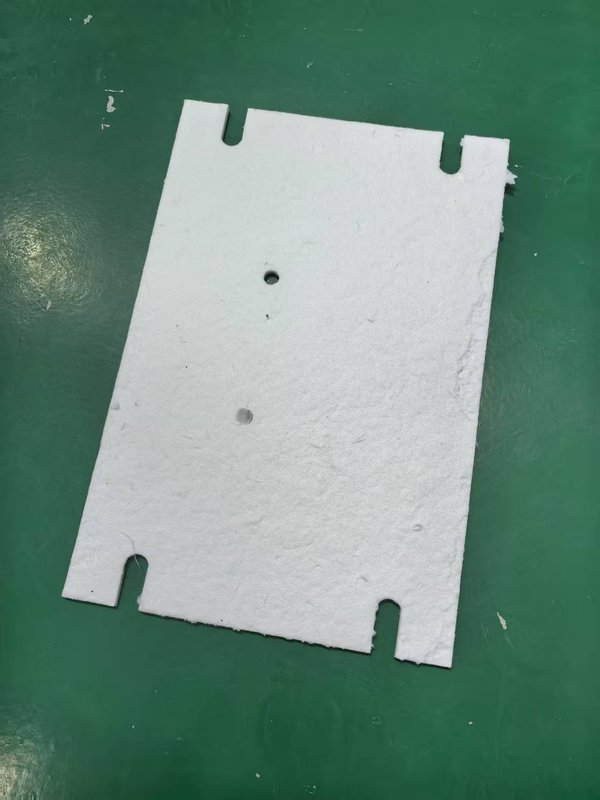

Aerogel felt is far more than fiber batt insulation. It is a composite of nanoporous silica aerogel and reinforced ceramic fibers, purpose-built to solve the toughest challenges in high-end construction:

Revolutionary Thermal Efficiency

Thermal conductivity as low as 0.015 W/(m·K) — delivering multiple times the insulation of conventional materials in minimal thickness, preserving structural lightness and design purity.

Extreme Environmental Stability

Operational range from −196°C (liquid nitrogen) to +650°C (industrial kilns). In Arctic stations or desert canopies, it maintains interior stability within ±2°C, shielding occupants and equipment from the harshest climates.

Inherent Safety & Durability

Fire Safety — A1 non-combustible (GB 8624-2012 / EN 13501-1): no melting, no toxic fumes, ensuring inherent safety for large public or high-risk spaces.

Hydrophobic & Moisture-Resistant — Contact angle >150°, hydrophobicity >98%. Prevents degradation and internal corrosion from dampness, vastly outlasting organic insulations.

Lightweight & Flexible — Core density 12–20 kg/m³, tensile strength ≥1.2 MPa. Bends, cuts, and conforms perfectly to complex double-curved membrane surfaces.

Part 2: System Enablement – Transforming Tensile Membrane Performance

We partner closely with leading global membrane system providers, positioning aerogel felt as the standard insulating core to create truly high-performance composites:

Typical Assembly — Outer PTFE fiberglass membrane (weather-resistant, self-cleaning, translucent) + Core layer (Hebei Woqin aerogel felt) + Inner acoustic liner.

Integrated Value

Energy Savings — An 8–10 mm aerogel felt layer can boost overall U-value by over 5×, slashing heating/cooling loads. Verified projects show up to 40% comprehensive energy savings.

Light Transmission & Comfort — Allows 15–20% soft, diffused natural light through, cutting daytime artificial lighting by up to 60% and eliminating glare.

Rapid Deployment & Mobility — Minimal weight enables massive spans without heavy foundations. A 500 m² super tent assembles in 24 hours, ideal for emergency shelters, temporary venues, and mobile facilities.

Part 3: Application Panorama – From Iconic Landmarks to Extreme Frontiers

Aerogel felt has already proven its value in demanding scenarios:

Large-Scale Sports & Public Facilities — Stadiums and airport terminals with long-span membrane roofs, balancing summer heat gain, winter heat loss, and abundant natural light.

Special Environment Buildings — Polar research stations, desert forward bases, high-altitude observatories—ensuring occupant comfort and equipment reliability in extreme climates.

High-End Commercial & Temporary Architecture — Luxury pop-up pavilions and eco-resorts, creating high-quality spaces that fuse aesthetics, light quality, and thermal comfort.

Industrial & Energy Sector — Insulation lining for LNG facility cladding and mobile enclosures, meeting stringent fire and durability requirements.

Part 4: The Woqin Partnership Model – From Material Supply to Co-Created Breakthroughs

We know integrating advanced materials involves technical, cost, and trust hurdles. That’s why we offer end-to-end partnership:

Technical Data & Simulation Support — Full third-party test reports (thermal, fire, hydrophobic, durability). We perform thermal performance simulation on your designs to quantify gains and optimize thickness.

Custom Development & Sampling — Cutting, pre-forming, composite lamination (foil, non-woven, etc.) tailored to your curvature, dimensions, and system needs.

Project Collaboration & On-Site Guidance — Application engineers provide hands-on support for handling, installation, and detail treatment, ensuring flawless execution.

Sustainability & Certification Support — Significantly lower whole-life carbon footprint. We supply data to support LEED, BREEAM, Three-Star Green Building, and other certifications.

Part 5: Vision for the Future – A New Paradigm of Light, Smart, Sustainable Architecture

Aerogel felt is more than an upgrade; it embodies a philosophy: maximum performance with minimal material, unlocking unprecedented formal freedom. It enables “mobile permanent architecture” and “self-sustaining extreme environment habitats.”

As global pressure mounts for decarbonization, resilient cities, and rapid deployment, lightweight, high-performance structures built around aerogel felt will be a defining technological pathway.

Initiate Your Project Evaluation

Step 1: Download the “Aerogel Felt for Architectural Systems White Paper” (free)

Includes TDS, typical assemblies with thermal calculations, global case studies, and comparative analysis vs. traditional insulation.

Step 2: Schedule a Dedicated Technical Discussion

Share your project overview or schematics. We’ll arrange a 45-minute online session with our architecture specialist to cover:

Material specification and cost optimization

System compatibility

Lifecycle TCO analysis

Contact Our Architectural Materials Division:

Hebei Woqin Trading Co., Ltd.

Phone / WeChat / WhatsApp: +86 139 3392 9092

Email: an@cn-aerogel.com (Subject: “Architectural Project Inquiry”)

Website:insulatewool.com

We look forward to co-creating the next landmark with you.

Written by - Zhongjian An

Certified Passive House Designer (PHI Germany), validated by Prof. Dr. Wolfgang Feist. With 15+ years of expertise in high-performance solutions for both Green Buildings and Industrial Applications (Petrochemical Pipelines, LNG Cryogenic, & High-Temp Equipment).

LATEST NEWS

Don't Be Fooled by Reflective Paints: Why Your Industrial Roof Gets Hot Again in Year Two

2026-02-19

Stop the Bulk: How to Choose the Right "Core" for Removable Insulation Jackets? (Aerogel vs. Rockwool Real-World Comparison)

2026-02-16

The "Great Squeeze" of 2026: Why Your 90-Day Terms Are Putting 25-Year Assets at Risk

2026-02-14

Closing the 0.005 W/mK Gap: How EV Battery Tech Solved a Passive House Thermal Bridge Nightmare

2026-02-12

The 98% UK Retrofit Failure: The Vapor-Open Aerogel Fix (μ<5)

2026-02-09