Hybrid Aerogel-VIP Composite: Breaking Thickness Limits – Hebei Woqin’s 2025 Solution for Space-Critical, High-Performance Insulation

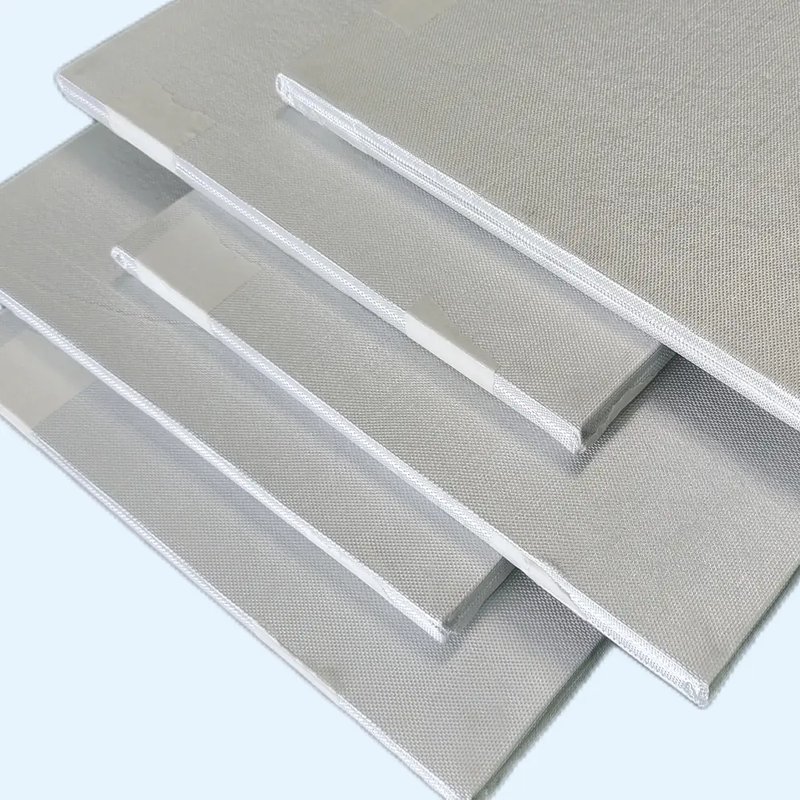

In space-constrained applications — from building retrofits with strict thickness limits to EV battery packs and industrial piping — traditional insulation forces painful trade-offs between performance, weight, and safety. Hebei Woqin Trading Co., Ltd. has developed a hybrid aerogel blanket fused with vacuum insulation panel (VIP) technology that eliminates these compromises. With verified thermal conductivity of 0.0015–0.0025 W/(m·K) (ASTM C518 equivalent & GB/T 10295-2008 aligned), this composite provides the insulating equivalent of 100 mm rock wool in just 10 mm , while maintaining A1/A2 fire safety, permanent hydrophobicity (>99%), and long-term durability. This is not just a new material — it is a design enabler that maximizes usable space, enhances safety, and reduces lifecycle costs in net-zero buildings, electric vehicles, and industrial processes.

Hybrid Aerogel-VIP Composite: Breaking Thickness Limits – Hebei Woqin’s 2025 Solution for Space-Critical, High-Performance Insulation

Engineers and architects face a universal constraint: space. This limitation forces compromises that undermine energy efficiency, safety margins, and operational costs — whether retrofitting historic facades, designing slimmer EV battery packs, or insulating high-temperature piping in crowded industrial plants.

Hebei Woqin Trading Co., Ltd. shatters this compromise with its 2025 breakthrough: a hybrid aerogel blanket fused with vacuum insulation panel (VIP) technology.

With verified thermal conductivity of 0.0015–0.0025 W/(m·K) (ASTM C518 equivalent & GB/T 10295-2008 aligned), this composite provides the insulating equivalent of 100 mm rock wool in just 10 mm, while maintaining A1/A2 fire safety, permanent hydrophobicity (>99%), and long-term durability.

This is not just a new material — it is a design enabler that maximizes usable space, enhances safety, and reduces lifecycle costs in net-zero buildings, electric vehicles, and industrial processes.

I. The Fusion Principle: Why 1+1 > 2

Traditional aerogel is lightweight and hydrophobic but limited by its intrinsic conductivity; VIP delivers near-zero gas conduction but is fragile and temperature-sensitive. Woqin’s hybrid solves both by complementary design.

Core Structure & Synergy

- A high-strength aerogel felt core (silica nanoparticles + glass fibers, tensile strength ≥1.2 MPa per GB/T 17911-2006) acts as a structural skeleton.

- This core is fully encapsulated in multi-layer vacuum envelopes (STP-grade, ≤10 Pa internal pressure).

- The aerogel skeleton supports the vacuum cavity against external pressure and puncture; the vacuum eliminates gas conduction and convection through the nanopores (20–50 nm).

Performance Leap

Lab tests show >80% reduction in thermal conductivity compared to standalone aerogel felt, achieving 0.0015 W/(m·K) at 25°C — matching or exceeding pure VIP performance in a more robust, flexible format.

Durability & Interface Engineering

- Proprietary high-temperature bonding (epoxy-silane hybrids, >1,200°C tolerance) prevents delamination under thermal cycling (–196°C to +200°C).

- Permanent hydrophobic silylation (contact angle >150°) ensures zero moisture uptake, eliminating degradation in humid environments.

- Accelerated aging (2,000 hours QUV equivalent + thermal shock) shows <1% drift, projecting 50+ year service life — significantly beyond rock wool (10–15 years) or conventional foams.

II. Solving Real-World Constraints: Two High-Impact Applications

The hybrid excels where space, performance, and safety cannot be compromised.

- Space-Critical Building Retrofits & Passive Design

Many existing buildings and heritage structures cannot accommodate thick insulation. The hybrid changes that. - EV Battery Thermal Management & Safety

Battery packs demand extreme space efficiency and runaway protection.

III. Safety, Sustainability & Future-Proof Design

The hybrid delivers more than performance:

- Fire Safety — A1/A2 class (no drips, self-extinguish <10 s).

- Environmental Profile — 30% lower production energy than foams; recyclable silica cores reduce mining impact (1 ton displaces 5 tons conventional).

- Future Integration — Sensor-ready variants (LoRaWAN) for predictive maintenance; phase-change doping for adaptive thermal storage.

IV. Woqin’s Commitment: From Lab to Global Deployment

Since 2018, Hebei Woqin has supplied advanced insulation to 20+ countries — from Europe’s nZEB projects to U.S. DOE pilots and Middle East oilfields. With 150+ patents and full turnkey support (custom density 100–300 kg/m³, valve shapes, ROI modeling), we make elite technology accessible and practical.

Conclusion: The New Standard for When Space & Performance Cannot Compromise

Hebei Woqin’s hybrid aerogel-VIP composite redefines what is possible when thickness is limited but performance is non-negotiable. It delivers unmatched thermal resistance, fire safety, and durability in minimal space — turning design constraints into competitive advantages.

The first step is to assess where this paradigm shift can benefit your project.

Contact Us for Project Assessment

Hebei Woqin Trading Co., Ltd.

Phone / WhatsApp / WeChat: +86 139 3392 9092

Email: an@cn-aerogel.com

Website: insulatewool.com

Request free technical data package, U-value calculations, or preliminary compliance & application assessment for your project.

Written by - Ruibin An

Industry Veteran with 13+ Years of Experience. Deeply rooted in the insulation industry for over 13 years, specializing in supply chain optimization and global market trends for Rock Wool and Aerogel materials.

LATEST NEWS

Don't Be Fooled by Reflective Paints: Why Your Industrial Roof Gets Hot Again in Year Two

2026-02-19

Stop the Bulk: How to Choose the Right "Core" for Removable Insulation Jackets? (Aerogel vs. Rockwool Real-World Comparison)

2026-02-16

The "Great Squeeze" of 2026: Why Your 90-Day Terms Are Putting 25-Year Assets at Risk

2026-02-14

Closing the 0.005 W/mK Gap: How EV Battery Tech Solved a Passive House Thermal Bridge Nightmare

2026-02-12

The 98% UK Retrofit Failure: The Vapor-Open Aerogel Fix (μ<5)

2026-02-09