Respect the Physics: Hebei Woqin’s 2026 Unified Thermal Insulation Standard – Choose Right, Protect Long-Term

“Why do we insulate? Not to pass an inspection, but to stop Entropy.” In Hebei Woqin’s laboratory, we don’t chase “price per cubic meter.” We study the Physics of Failure — the real thermodynamic and mechanical reasons insulation systems degrade, lose performance, or become dangerously expensive over time. The conventional lowest-bid approach often overlooks first principles: water turns insulation conductive (k ≈ 0.6 W/(m·K) at 20°C), heat degrades vacuum barriers, vibration collapses weak structures. What appears as upfront savings frequently becomes compounded lifecycle costs: multiplied energy loss, accelerated corrosion under insulation (CUI), early replacement, and hazardous waste disposal. This article introduces our 2026 Unified Thermal Spectrum — a first-principles selection framework derived from rigorous destruction testing. It maps each material’s true safe operating zone, reveals hidden lifecycle risks, and offers engineer-to-engineer guidance to help you choose insulation that lasts decades, not months.

Respect the Physics: Hebei Woqin’s 2026 Unified Thermal Insulation Standard – Choose Right, Protect Long-Term

Respect the Physics: Hebei Woqin’s 2026 Unified Thermal Insulation Standard – Choose Right, Protect Long-Term

“Why do we insulate? Not to pass an inspection, but to stop Entropy.”

In the Hebei Woqin Laboratory, we don’t optimize for “price per cubic meter.” We study the Physics of Failure — the real thermodynamic and mechanical reasons insulation systems degrade, lose performance, or become dangerously expensive over time.

The conventional lowest-bid approach often overlooks first principles:

- Water is highly conductive (k ≈ 0.6 W/(m·K) at 20°C — 15–20× higher than dry insulation).

- Heat degrades vacuum barriers in VIPs.

- Vibration and thermal cycling collapse weak fiber structures.

Selecting insulation based solely on initial cost frequently leads to compounded lifecycle costs: multiplied energy loss, accelerated corrosion under insulation (CUI), early replacement, and hazardous waste disposal.

Below is our 2026 Woqin Unified Thermal Spectrum — a first-principles selection framework derived from rigorous destruction testing and long-term field validation. It maps each material’s true safe operating zone and helps engineers and procurement teams choose the right solution for the right application.

Part 1: The Unified Thermal Spectrum – One Material Cannot Rule Them All

We evaluated our entire product line against physical realities. This table shows ideal operating ranges, physical hard limits, thermal conductivity, and Hebei Woqin’s practical verdict.

| Material Type | Ideal Operating Range | Physical Hard Limit | Thermal Conductivity | Hebei Woqin Verdict |

|---|---|---|---|---|

| VIP (Vacuum Panel) | Cryogenic (–196°C) | ≤ 100°C | 0.0025 W/(m·K) | The cryogenic specialist. Do NOT use for high-temperature steam. Gas barrier films degrade >100°C. |

| Aerogel Coating | Ambient to 200°C | ≤ 240°C | 0.032 W/(m·K) | The geometry solver. Seamless spray for complex valves & flanges. Online application possible. |

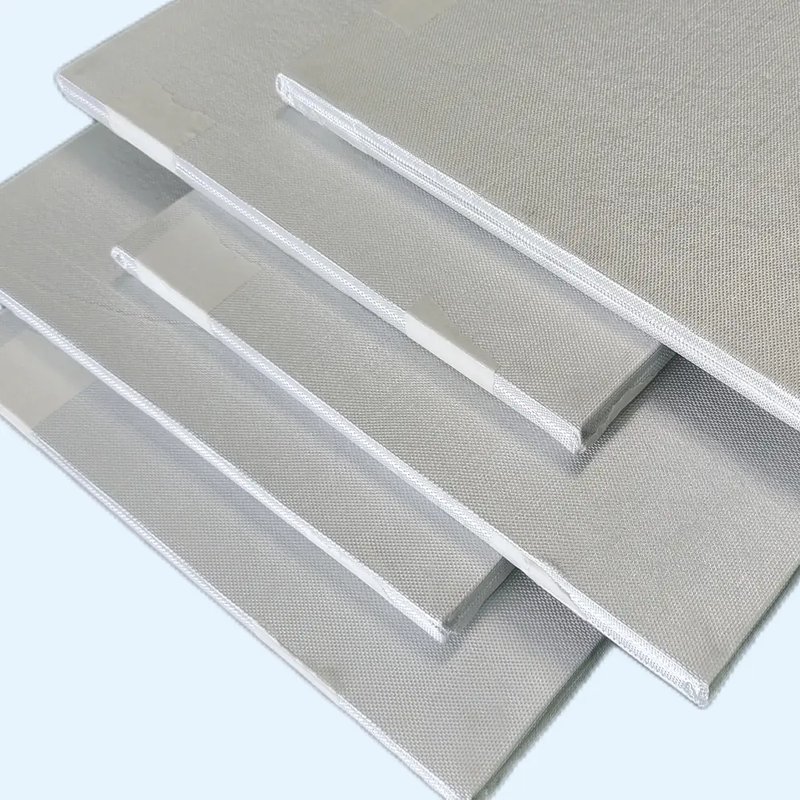

| Aerogel Blanket | –200°C to 650°C | ≤ 650°C | 0.020 W/(m·K) | The space saver. Replaces rock wool at 1/5 thickness. >99% Hydrophobic. |

| Rock Wool (Industrial) | Ambient to 500°C | ≤ 600°C | 0.044 W/(m·K) | The conventional workhorse – mindful of moisture & long-term integrity risks (CUI, fiber degradation). |

| Ceramic Fiber | 600°C to 1000°C | ≤ 1260°C | 0.134 W/(m·K) | The high-temperature shield. The safe choice for cracking furnaces & kilns. A1 non-combustible. |

Part 2: The “Wet Cotton” Effect – How Moisture Turns Insulation into a ConductorQuestion: Why can “conventional” rock wool become the most expensive option over time?

The Physics:

Liquid water (at ~20°C) has a thermal conductivity of approximately 0.6 W/(m·K) — about 15–20 times higher than dry insulation media.

The Reality Scenario:

- You select non-hydrophobic rock wool to reduce upfront cost.

- Rain, condensation, or cladding leaks occur (they almost always do).

- The wool absorbs water like a sponge.

- Result: You are now wrapping your hot pipe with wet cotton. You are not insulating it; you are conducting heat directly to the surface.

- The Hidden Costs:

The Woqin Standard: We design for reality. Water must not enter.

All Hebei Woqin Aerogel series feature >99% hydrophobicity — actively repelling water to maintain declared performance for the long term.

Part 3: Engineer-to-Engineer FAQQ1: Can Vacuum Insulation Panels (VIP) be used on a 300°C steam line?Hebei Woqin Lab Answer: Absolutely not. Physics dictates that at sustained temperatures above 100–120°C, the gas barrier film degrades and the core outgasses. Once vacuum is lost, the panel becomes ordinary plastic with zero insulation value.

Our Advice: Reserve VIPs for cryogenic (–196°C) or cold-chain applications. For steam, use Aerogel Blankets. Result: Reliable performance without vacuum failure risk.

Q2: Datasheets claim rock wool works up to 600°C. Is this accurate for long-term use?Hebei Woqin Lab Answer: Yes for short-term fire rating — the binder may burn off, but the material can hold shape for ~120 minutes. For continuous industrial operation, however, it sags and powderizes at extreme temperatures.

Our Advice: If your process consistently exceeds 600°C, upgrade to Hebei Woqin Ceramic Fiber, stable up to 1260°C. Result: No structural degradation or frequent replacement.

Q3: We have a leaking valve at 110°C and cannot shut down. What’s the solution?Hebei Woqin Lab Answer: This is the classic “Online Repair” paradox — you cannot perfectly wrap a blanket around a complex valve while it’s hot.

Our Advice: Use Aerogel Insulation Coating. Water-based but heat-reactive, it can be sprayed directly onto hot surfaces (up to 200°C operating). It cures instantly, forms a seamless bond, and eliminates energy bleed — zero downtime. Result: Immediate heat loss stopped, repair deferred to next planned shutdown.

Conclusion: Long-Termism & Your Next Step

In essence, proper insulation is an applied battle against entropy — it maintains order (temperature differential) and prevents the costly decay of your assets.

When you choose Hebei Woqin, you are investing in Thermodynamic Certainty — insulation that respects physics, defeats entropy, and protects your assets for decades, not months.

Free Offer: Thermal Integrity Preliminary Diagnosis

Submit your key pipeline parameters (Medium, Operating Temperature, Current Insulation). Our engineers will evaluate your system based on the 2026 Woqin Standard:

- Risk Assessment: Theoretical lifespan & potential “Wet Cotton” / CUI risk points

- Optimization: Specific material suggestions & thickness comparison based on the Unified Spectrum

- Cost Analysis: Concise Lifecycle Cost Analysis (LCCA)

Contact Us

Hebei Woqin Trading Co., Ltd.

Phone / WhatsApp / WeChat: +86 139 3392 9092

Email: an@cn-aerogel.com

Website:insulatewool.com

Written by - Ruibin An

Industry Veteran with 13+ Years of Experience. Deeply rooted in the insulation industry for over 13 years, specializing in supply chain optimization and global market trends for Rock Wool and Aerogel materials.

LATEST NEWS

Don't Be Fooled by Reflective Paints: Why Your Industrial Roof Gets Hot Again in Year Two

2026-02-19

Stop the Bulk: How to Choose the Right "Core" for Removable Insulation Jackets? (Aerogel vs. Rockwool Real-World Comparison)

2026-02-16

The "Great Squeeze" of 2026: Why Your 90-Day Terms Are Putting 25-Year Assets at Risk

2026-02-14

Closing the 0.005 W/mK Gap: How EV Battery Tech Solved a Passive House Thermal Bridge Nightmare

2026-02-12

The 98% UK Retrofit Failure: The Vapor-Open Aerogel Fix (μ<5)

2026-02-09