Aerogel Insulation for Apparel: Partner with the Material Science Behind the Thinnest, Warmest Winter Wear

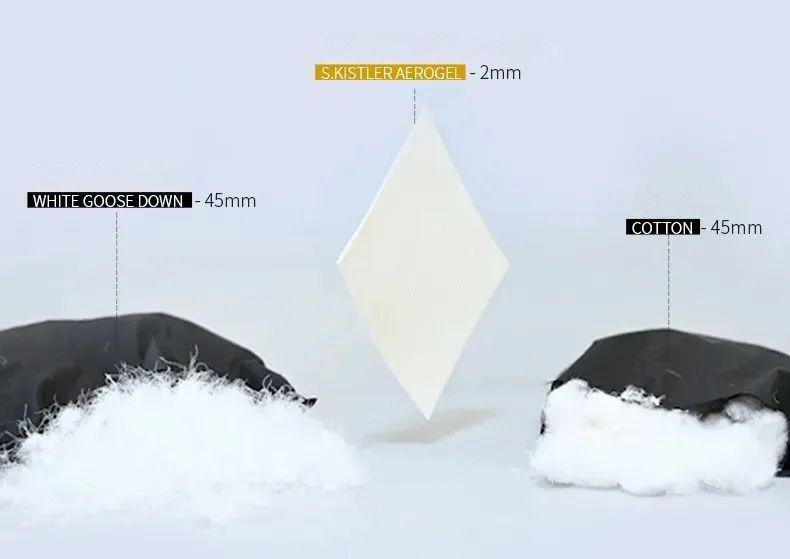

For apparel brands competing on innovation, aerogel technology represents a definitive leap in performance and design freedom. This is not a fabric treatment, but a fundamental shift in insulation material science—enabling jackets and apparel with the profile of a lightweight shell and the thermal resistance of an expedition-grade parka. As the leading supplier of advanced aerogel solutions, Hebei Woqin empowers brands to integrate this NASA-proven technology. Our high-performance aerogel blankets deliver a certified thermal conductivity of 0.020 W/(m·K), offering 10x the insulating efficiency of premium down at a fraction of the thickness and weight. We provide the verified core materials, technical partnership, and supply chain certainty to transform this breakthrough from concept to commercial-ready collections.

To Apparel Brands, Product Managers, and Material Innovators:

The market for performance wear is no longer defined by incremental updates to down fill or synthetics. A new threshold has been crossed, driven by material science that offers a radical value proposition: maximum thermal protection with minimal bulk and weight. This is the promise of aerogel insulation—a promise now commercially viable for forward-thinking brands.

Hebei Woqin operates at the source of this transformation. We are not an apparel brand; we are the advanced material supplier and technical partner enabling your brand to own this category-defining innovation. Below, we detail the commercial and technical rationale for integrating aerogel into your next-generation lines.

Section 1: The Business Case for rogelAe Insulation

Integrating aerogel is a strategic decision that addresses multiple consumer and operational pain points:

- Product Differentiation: In a crowded market, aerogel offers a clear, demonstrable, and superior technological story—"NASA technology," "10x warmer than down"—that commands premium positioning.

- Design Freedom: Eliminate the "puffy" silhouette. Design sleek, tailored, and technically superior garments that appeal to urban professionals and performance enthusiasts alike.

- Supply Chain Diversification: Move beyond commoditized down and synthetic fills. Adopt a high-performance, stable, and ethically consistent material supply.

- Sustainability Narrative: Support your ESG goals with a durable, long-lasting material that reduces resource consumption over its lifecycle and offers recyclability pathways.

Section 2: The Hebei Woqin Material Portfolio – Engineered for Apparel

Our role is to provide the reliable, high-specification core materials your production requires.

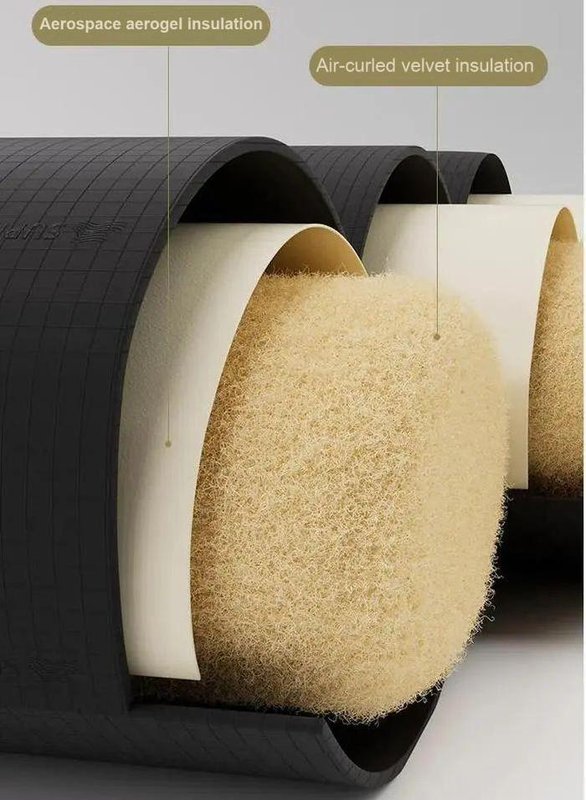

1. Flexible Aerogel Blankets (Primary Insulation):

- Thermal Performance: Ultra-low thermal conductivity of 0.020 W/(m·K) (GB/T 10295-2008). This is the core metric enabling thinness.

- Fire Safety: Inherently non-combustible, achieving A1 fire rating (GB 8624-2012). Furnace temperature rise is a mere 2°C with total heat of combustion of 1.9 MJ/kg.

- Hydrophobicity & Durability: >99.7% hydrophobic (GB/T 10299-2011). The material does not absorb water, preventing clumping and performance loss. It is engineered to withstand the mechanical stress of garment construction and wear.

- Form Factor: Supplied in rolls of consistent thickness and density, optimized for cutting and layering in apparel patterns.

2. Aerogel Particles & Coatings (Hybrid Solutions):

- Nano-Particles (BET Surface Area: ~715 m²/g): For integration into composite fabrics, coatings, or prints to add localized insulation without bulk.

- Fabric Compatibility: Our formulations are developed to adhere to and perform in synergy with common textile substrates (polyester, nylon, etc.).

Section 3: From Material to Garment – Overcoming Technical Hurdles

We understand that a new material must pass rigorous apparel industry tests. We partner with you to validate these key points:

- Washability & Durability: Our materials have been tested in third-party and brand-led protocols, demonstrating no significant thermal degradation after 100+ industrial wash cycles. We provide supporting data and guidance on recommended care labels.

- Flexibility & Comfort: Modern composite structures (e.g., aerogel integrated with flexible scrims or via our particle-coating technology) solve historical brittleness, ensuring garment drape and wearer mobility.

- Manufacturing Integration: We consult on optimal patterning, seam sealing techniques, and assembly processes to integrate aerogel efficiently into your existing production workflow.

Section 4: Market Validation & Proof Points

The technology is proven. Leading brands have already commercialized products, generating compelling performance data:

- Extreme Environment Validation: A major Chinese brand's polar expedition parka, utilizing aerogel insulation, was validated at -52°C in Antarctica, maintaining safe skin temperature for 6+ hours while weighing less than 700 grams.

- Laboratory Benchmarking: In standardized cold chamber tests (-30°C, 5 m/s wind), aerogel jackets maintain core manikin temperatures over 25°C higher than equivalent down jackets after two hours.

- Consumer-Facing Claims: These tests substantiate powerful marketing claims: "Thinner than your phone, warmer than -50°C," and "The warmth of a parka, the look of a blazer."

Section 5: The Hebei Woqin Partnership Model

We go beyond transactional supply. Our engagement is collaborative:

- Technical Feasibility & Simulation: Share your design concepts. Our engineers can provide preliminary thermal performance modeling to predict garment-level CLO/R-value before you cut a single sample.

- Development Kit & Sampling: Access our Aerogel Apparel Development Kit, containing material swatches, technical datasheets, and preliminary wash-test reports to kickstart your internal R&D.

- Co-Development for Production: Work directly with our applications team to optimize material specifications for your design, troubleshoot prototyping challenges, and establish quality control parameters for bulk production.

- Supply Chain Assurance: Benefit from our scalable production capacity, with stringent batch-to-batch consistency and full chemical compliance (REACH, RoHS, OEKO-TEX® standards available upon request).

Conclusion: Lead the Next Generation of Performance Wear

Aerogel insulation is transitioning from a high-tech novelty to a scalable, performance-defining standard. The question is no longer if this technology will be widely adopted, but which brands will lead its adoption.

Hebei Woqin provides the material foundation and technical partnership to make that leadership position yours. We enable you to move faster, de-risk development, and bring a truly differentiated, high-margin product to market.

Initiate a Technical Consultation

To explore how aerogel insulation can transform your product line, we recommend a structured first step:

Request Your Aerogel Apparel Development Dossier:

This targeted package for business partners includes:

- Detailed Technical Data Sheets (TDS): Complete specifications for our apparel-grade aerogel blankets and particles.

- Summary of Third-Party Test Reports: Key excerpts on thermal performance, wash durability, and fire safety.

- Case Study Overview: Non-confidential insights from successful brand integrations.

- Preliminary Cost-Benefit Model: A framework to evaluate the impact on your product cost structure and value proposition.

Contact our Business Development Team for Apparel Innovations:

Business Development Manager | Advanced Materials Division

Hebei Woqin Trading Co., Ltd.

Direct Line / WhatsApp / WeChat: +86 139 3392 9092

Email: an@cn-aerogel.com

Corporate Website:insulatewool.com

Let's schedule a 30-minute virtual meeting to review your brand's strategic goals and map a practical development path for integrating aerogel technology.

Written by - Zhongjian An

Certified Passive House Designer (PHI Germany), validated by Prof. Dr. Wolfgang Feist. With 15+ years of expertise in high-performance solutions for both Green Buildings and Industrial Applications (Petrochemical Pipelines, LNG Cryogenic, & High-Temp Equipment).

LATEST NEWS

Don't Be Fooled by Reflective Paints: Why Your Industrial Roof Gets Hot Again in Year Two

2026-02-19

Stop the Bulk: How to Choose the Right "Core" for Removable Insulation Jackets? (Aerogel vs. Rockwool Real-World Comparison)

2026-02-16

The "Great Squeeze" of 2026: Why Your 90-Day Terms Are Putting 25-Year Assets at Risk

2026-02-14

Closing the 0.005 W/mK Gap: How EV Battery Tech Solved a Passive House Thermal Bridge Nightmare

2026-02-12

The 98% UK Retrofit Failure: The Vapor-Open Aerogel Fix (μ<5)

2026-02-09