The 98% UK Retrofit Failure: The Vapor-Open Aerogel Fix (μ<5)

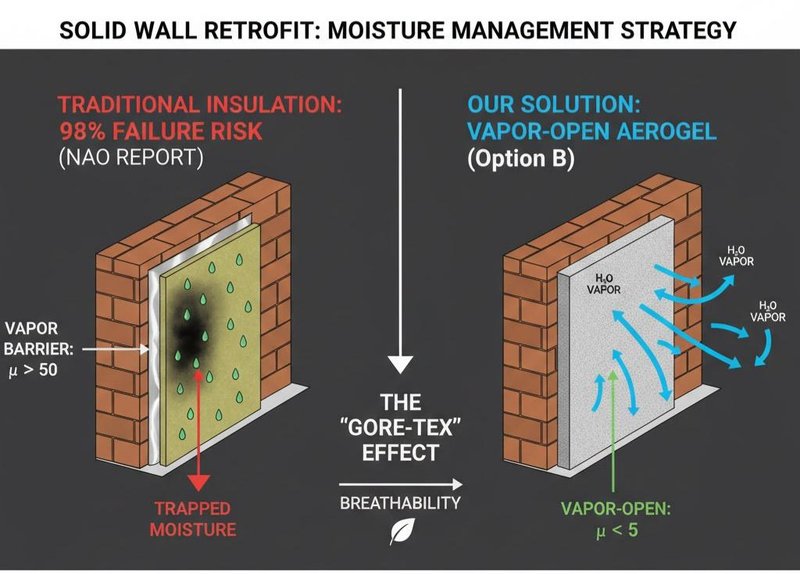

A recent NAO report reveals a shocking 98% failure rate in UK retrofits due to damp and mold. This article analyzes the physics behind the "Sweatbox Effect" caused by traditional non-breathable insulation. We present a scientific solution: Hydrophobic Aerogel (Option B) with a μ-value < 5, proving why "going foil-free" is the only way to prevent structural decay in solid wall buildings.

Yesterday, a shocking report from the National Audit Office (NAO) regarding the UK's recent energy efficiency schemes revealed a devastating statistic: an overwhelming 98% of homes insulated under these programs are now facing issues with damp, mold, or decay.

For architects, specifiers, and retrofit contractors, this is a critical lesson in material science. While heartbreaking for homeowners, frankly, it is not surprising.

When you wrap a historical British home (solid brick or stone) in non-breathable cheap insulation, you are effectively putting a plastic bag over a runner who is sweating. The moisture has nowhere to go. It gets trapped. And inevitably, the rot sets in.

The "Physics" of Failure: The Sweatbox Effect

The BBC report highlights "poor workmanship" and "rainwater trapping" as key culprits. But the fundamental issue is a clash of materials.

Traditional insulation materials (like foil-faced PIR or standard cementitious renders) often block the natural vapor drive of the building.

- The Problem: Internal moisture tries to escape through the walls but hits a barrier.

- The Result: Interstitial Condensation forms behind the insulation.

- The Consequence: Black mold, respiratory issues, and structural damage.

The Solution: The "Gore-Tex" Effect (Low μ-Value)

At our manufacturing facility, we have been obsessed with one question: How do we insulate without suffocating the building?

The answer lies in Aerogel Technology.

Unlike foam boards, Silica Aerogel is unique. It is naturally Hydrophobic (repels liquid water) but highly Vapor Permeable (allows steam to escape).

The Data: Why Breathability Matters

We compared the water vapor resistance of standard solutions versus our engineered Aerogel system. The difference is stark:

Conclusion: The lower the μ-value, the better the breathability. Our system is 10x more breathable than traditional foil-faced PIR, effectively eliminating the risk of internal condensation.

This means our system works exactly like high-end outdoor gear:

- Stops the Rain: Prevents external water ingress.

- Lets it Breathe: Allows internal moisture vapor to dry out effectively.

Why We Removed the Foil: The "Option B" Strategy

To specifically address the crisis mentioned in the NAO report, we engineered our Option B (Breathable, Foil-Free Aerogel Composite) specifically for solid wall retrofits.

Based on our internal testing and field applications, we intentionally removed the aluminum foil layer.

By combining Aerogel Blankets with a breathable, A1 Fireproof Mineral Composite face, we achieve a system that:

- Insulates: With an ultra-low thermal conductivity of 0.020 W/mK.

- Protects: Withstands 650°C+ heat and fire (A1 Class).

- Breathes: Ensuring that the "98% failure rate" becomes a thing of the past for your projects.

Conclusion

The "98% failure rate" is a wake-up call. We cannot solve today's energy crisis with yesterday's cheap, non-breathable materials.

Get the Hard Data for Your Next Project:

- Download: Get our "Solid Wall Retrofit Guide" including full μ-value data and junction details.

- Free Assessment: Send us your project drawings for a Quick Condensation Risk Analysis.

Written by - Zhongjian An

Certified Passive House Designer (PHI Germany), validated by Prof. Dr. Wolfgang Feist. With 15+ years of expertise in high-performance solutions for both Green Buildings and Industrial Applications (Petrochemical Pipelines, LNG Cryogenic, & High-Temp Equipment).

LATEST NEWS

The 98% UK Retrofit Failure: The Vapor-Open Aerogel Fix (μ<5)

2026-02-09

10mm vs 150mm: The Truth About Guy Martin's Retrofit Challenge

2026-02-07

Respect the Physics: Hebei Woqin’s 2026 Unified Thermal Insulation Standard – Choose Right, Protect Long-Term

2026-02-06

If the Tang Dynasty Had VIPs: Why Modern Luxury Food Delivery Needs "Vaccine-Grade" Protection

2026-02-05

Stop the Silent Killer: Why Your Wall is Rotting at -20°C (And How WOqin Ends the "Phantom Ice" Crisis)

2026-02-04