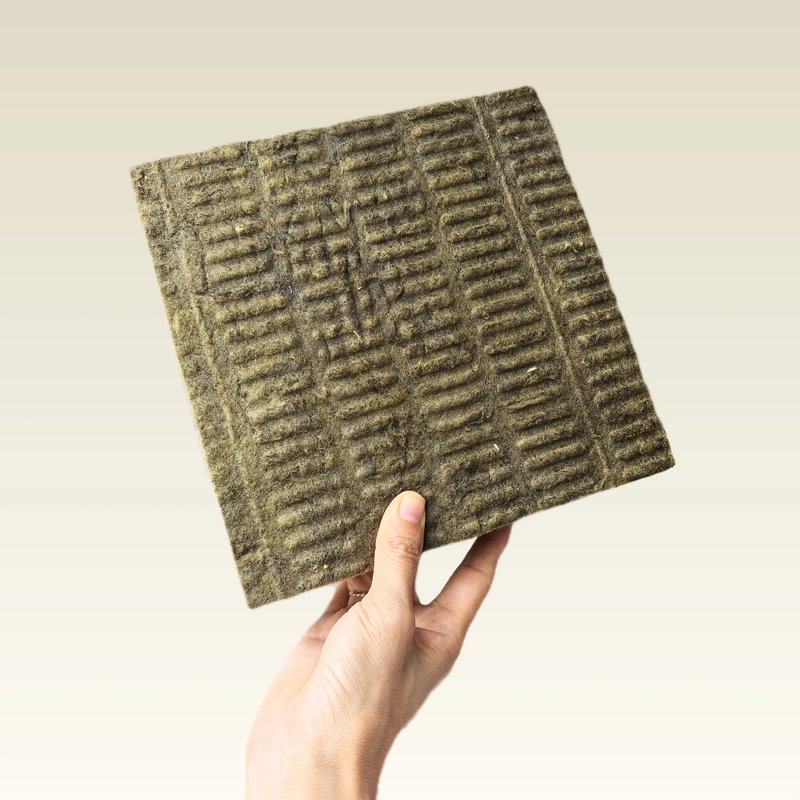

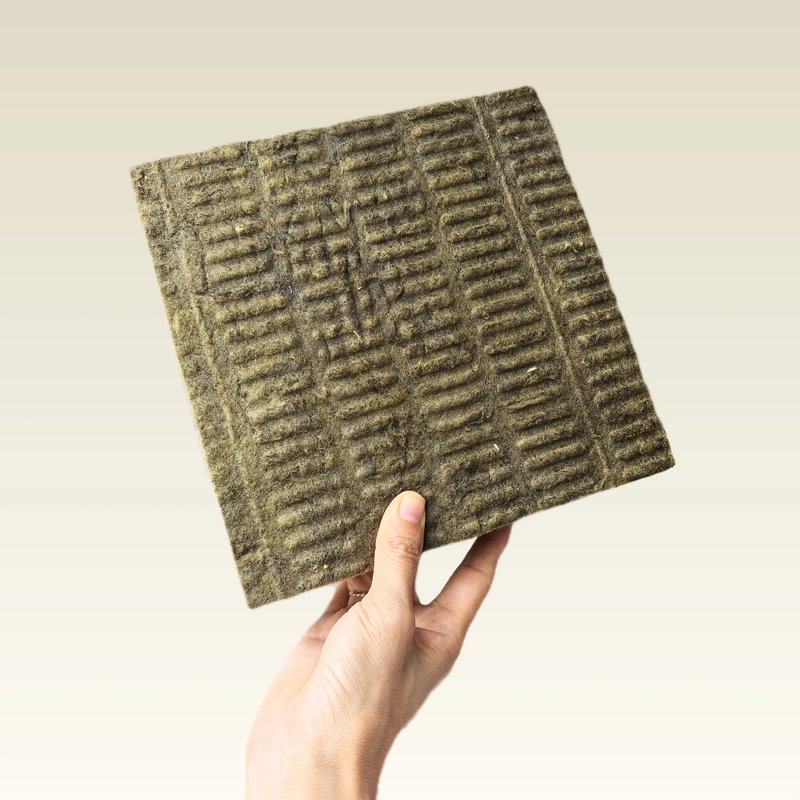

Silica Aerogel Insulation Blanket | High-Density Nano-Porous Industrial Felt (-200°C to 650°C)

PRODUCT INTRODUCTION

Hebei Woqin provides professional-grade Silica Aerogel Blankets for heavy industrial and cryogenic applications. With a thermal conductivity of 0.020 W/(m·K), it is the ideal solution for Oil & Gas pipelines (LNG/LPG), refinery equipment, and high-temperature steam networks. Resistant from -200°C to +650°C, it prevents CUI (Corrosion Under Insulation) and survives extreme vibration.

| Serial No. | Test Item | Sub-item | Test Basis | Specification Requirement | Test Result | Unit | Individual Judgment |

|---|---|---|---|---|---|---|---|

| 1 | Vibration Mass Loss Rate | - | GB/T 34336-2017 Appendix B | ≤1.0 | 0.3 | % | Conform |

| 2 | Hydrophobic Rate | - | GB/T 10299-2011 | ≥98.0 | 99.7 | % | Conform |

| 3 | Thermal Conductivity | Average Temperature 25℃ | GB/T 10295-2008 | ≤0.021 | 0.02 | W/(m·K) | Conform |

| Average Temperature 300℃ | GB/T 10294-2008 | —— | 0.039 | W/(m·K) | —— | ||

| 4 | Tensile Strength | Transverse | GB/T 17911-2006 9 | ≥200 | 1255 | kPa | Conform |

| Longitudinal | 414 | kPa | Conform | ||||

| 5 | Combustion Performance (Class A (A1)) | Combustion Calorific Value | GB/T 14402-2007 | ≤2.0 | 1.9 | MJ/kg | Conform |

| Mass Loss Rate | GB/T 5464-2010 | ≤50 | 2.1 | % | Conform | ||

| Furnace Temperature Rise | ≤30 | 2 | ℃ | Conform | |||

| Sustained Burning Time | 0 | 0 | s | Conform |

Silica Aerogel Insulation Blanket | High-Density Nano-Porous Felt

The "Space-Age" Replacement for Traditional Wool:

Upgrade your industrial insulation from outdated bulk materials to advanced Nano-Technology. Our Silica Aerogel Blanket delivers industry-leading performance (0.020 W/m·K), effectively doing the work of 100mm traditional foam with just 20mm of thickness. This ultra-thin profile not only saves valuable space but slashes logistics costs by 80%, making it the ultimate solution for high-value pipelines and extreme environments.

Key Technical Data (ASTM C177 Certified):

- Thermal Conductivity: 0.020 W/(m·K) (at 25°C) — Accurate precision data; zero over-marketing.

- Temperature Range: -200°C to +650°C (Standard Grade); Custom composite versions available up to +1200°C.

- Hydrophobicity: > 99% — Molecular-level water repellency ensures the substrate stays bone-dry.

- Fire Rating: Class A1 / UL94 V0 — Non-combustible, zero smoke generation.

- Tensile Strength: ≥ 1255 kPa — High mechanical strength; will not collapse under vibration.

- Thickness Options: 3mm, 6mm, 10mm, 20mm (Standard Rolls).

Why This Matters for Your Project:

- Eliminate CUI (Corrosion): Unlike mineral wool which acts as a sponge, our hydrophobic aerogel repels water completely, extending pipeline lifespans by 15-20 years.

- Space & Weight Optimization: Saves 80% of installation space. Ideal for EV battery packs, submarines, and cramped pipe racks where every millimeter counts.

- Vibration Resistant: Passed MIL-STD-810G vibration tests. The felt does not crumble or settle under the constant mechanical stress of ships or industrial pumps.

- Health & Safety: Non-carcinogenic and low-dust, ensuring a safe working environment compared to fiberglass.

Applications:

- Petrochemical & LNG: Cryogenic pipelines and reaction vessels (-200°C stability).

- New Energy Vehicles (EV): Thermal runaway barriers between battery cells.

- District Heating: High-pressure steam pipe wrapping (replacing bulky jackets).

- Aerospace: Satellite vacuum insulation and rocket engine thermal shields.

⚠️ Customization Service:

- Precision Cutting: Free CAD-based cutting for irregular shapes (valve covers, battery mats).

- Surface Laminations: Available with Adhesive Backing, Aluminum Foil, or Fiberglass Cloth facing.

Fast Quote

Get a price for Silica Aerogel Insulation Blanket | High-Density Nano-Porous Industrial Felt (-200°C to 650°C)

CONTACT US

RELATED PRODUCTS

NEW

High-Purity Ceramic Fiber Needle Blanket | 1260°C Grade Refractory Insulation

Professional grade alumina-silicate fiber...

Ultra-High Strength Graphite EPS Insulation Sub-frame | 2090 kPa Compression Resistance

Engineered for extreme structural integrity,...

Premium Rock Wool Insulation Boards | Factory Direct Bulk Supply (A1 Fireproof)

Manufactured from high-purity basalt ore using...

Ultra-High Purity Silica Aerogel Block | The 0.0146 W/(m·K) Laboratory Standard for Thermal Nanotechnology

Hebei Woqin establishes a new global benchmark...

Advanced Silica Aerogel Insulation Coating | 2mm Replaces 40mm Traditional Foam

Hebei Woqin presents a revolutionary...

High-Purity Silica Aerogel Powder | Ultra-Low 0.015 W/(m·K) Nano-Insulation

Hebei Woqin offers premium silica aerogel...

RELATED PRODUCTS

High-Purity Ceramic Fiber Needle Blanket | 1260°C Grade Refractory Insulation

Professional grade alumina-silicate fiber blanket verified by Lab Report ....

Ultra-High Strength Graphite EPS Insulation Sub-frame | 2090 kPa Compression Resistance

Engineered for extreme structural integrity, our Graphite EPS Sub-frame...

Premium Rock Wool Insulation Boards | Factory Direct Bulk Supply (A1 Fireproof)

Manufactured from high-purity basalt ore using our advanced low-slag...

Ultra-High Purity Silica Aerogel Block | The 0.0146 W/(m·K) Laboratory Standard for Thermal Nanotechnology

Hebei Woqin establishes a new global benchmark for solid-state insulation...

Advanced Silica Aerogel Insulation Coating | 2mm Replaces 40mm Traditional Foam

Hebei Woqin presents a revolutionary nanostructured aerogel coating with...

High-Purity Silica Aerogel Powder | Ultra-Low 0.015 W/(m·K) Nano-Insulation

Hebei Woqin offers premium silica aerogel powder with an industry-leading...