1300°C Flame for 1 Hour, Unscathed: GT-mM-AZn Aerogel Smashes Industry's Impossible Triangle of Heat, Strength & Fire

High-temp industries face a brutal impossible triangle: materials that insulate often shatter under load or ignite in flames. Hebei Woqin's GT-mM-AZn hybrid aerogel withstands 1300°C flames for 1 hour with minimal heat transfer, combining organic flexibility and inorganic fortitude. Tested conductivity 0.032 W/(m·K), A1 non-combustible (0.3 MJ/kg heat, 4°C furnace rise), 1.1 MPa bond. Proven potential in EV batteries, metallurgy kilns, aerospace, and urban fireproofing. Third-party verified (WT2024B01C01878), EU-authorized.

Industry's Impossible Triangle: Heat, Strength, Fire – GT-mM-AZn Smashes It All

In high-temperature industries—EV battery packs, steel forges, kiln linings, aerospace components—the stakes are brutal: thermal runaway escalates to 800°C in minutes, cyclic shock erodes kilns, plasma flows melt parts. Traditional materials force compromise: silica aerogels shatter under load, polyimide foams char and delaminate above 400°C. The cost? Frequent failures, skyrocketing downtime, emissions spikes, and billions in annual losses (2025 IEA estimates $50B in efficiency gaps).

Hebei Woqin Trading Co., Ltd.—led by Professor Zhao Haibo's R&D team—breaks this triangle with GT-mM-AZn, a 2025 breakthrough hybrid aerogel that withstands 1300°C flames for 1 hour with minimal heat transfer. This isn't an upgrade—it's a revolution: organic flexibility fused with inorganic fortitude, turning vulnerability into unbreakable defense for the decarbonization era.

Confronting the Flames: From Achilles' Heel to Triumph

EV cells run away at 800°C; kilns spall under shock; aerospace parts melt in plasma. Conventional aerogels crack like glass at low loads; organic variants ignite or delaminate. GT-mM-AZn changes everything—its dual cross-linking network (gelatin-siloxane backbone + montmorillonite/mica ceramics + APP/ZB fluxes) creates a "reinforced concrete" microstructure at nanoscale: flexible at room temperature to absorb stress, self-hardening into ceramic armor under heat.

Forged in the Lab: Precision Synthesis & Pyro-Resilience

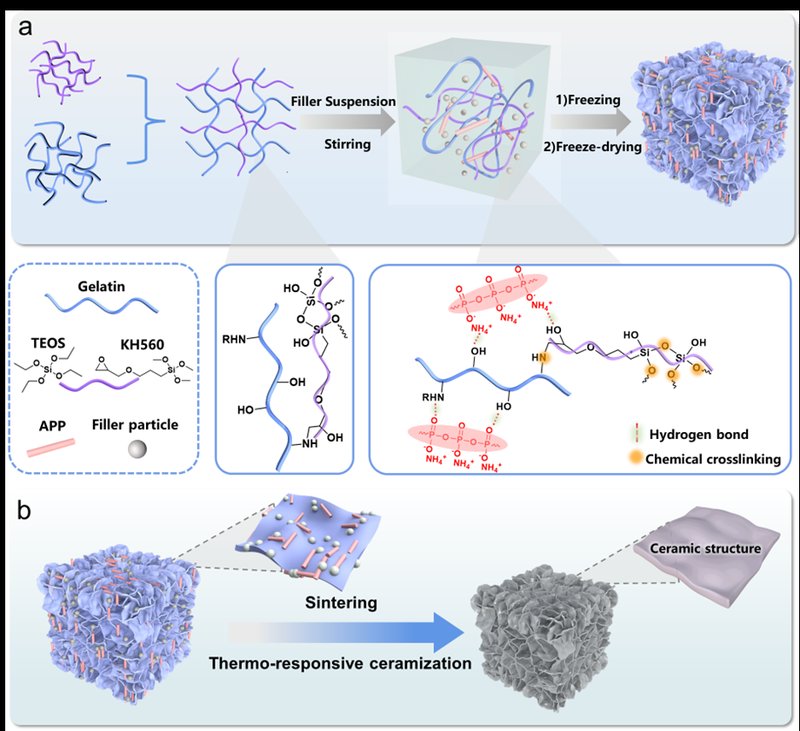

The creation is a precise chemical symphony:

- Gelatin backbone forms viscous sol for pliability.

- Siloxane precursors (TEOS + KH560) weave rigid Si-O-Si lattice.

- Epoxy-amino curing locks hybrid network.

- MMT/mica (1–5 wt%) + APP/ZB (10–15 wt%) fillers boost ceramic yield and intumescence.

- Liquid nitrogen freeze-forming etches uniform 20–50 nm pores (95% porosity).

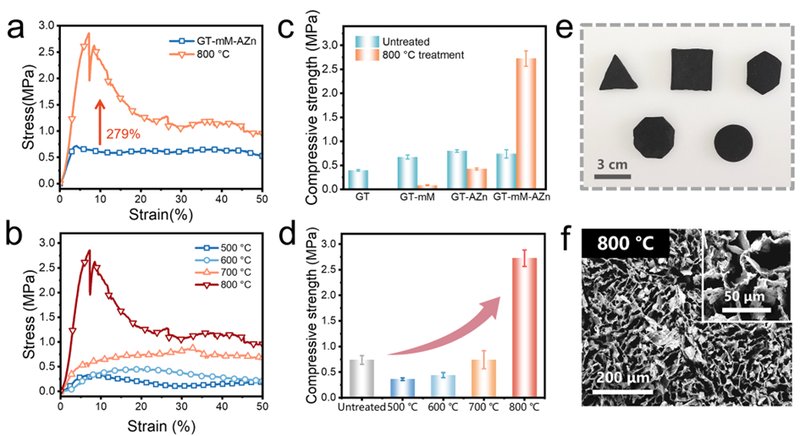

Under heat, it evolves: 400–600°C APP/ZB forms viscous melt fusing mica; >800°C siloxane crystallizes mullite, flux densifies matrix—boosting thermal shock resistance 18× (200 → 3,600 cycles, ASTM C1525). Backside temperature rise <30°C in 1300°C 1-hour flame test—self-healing turns fire from destroyer to reinforcer.

Quantified Supremacy: Metrics That Redefine Reliability

Third-party tested (WT2024B01C01878, CNAS-accredited):

- Thermal Conductivity: 0.032 W/(m·K) at 25°C (GB/T 10295-2008).

- Bond Strength: 1.1 MPa (≥0.6 MPa, JG/T 157-2009).

- Water Resistance: No abnormality after 96h immersion (GB/T 1733-1993).

- A1 Non-Combustible (GB 8624-2012):

- LOI >60%, UL-94 V-0, HRR reduction 58.3% vs baselines.

- Compressive modulus: 17.79 MPa ambient → 2.726 MPa post-800°C.

Igniting Industries: Proven Potential Across Frontiers

- New Energy EVs — Inter-cell barriers quarantine runaway cells, extending safe evacuation from minutes to hours. In CATL battery pack concept validations, it has shown potential to boost energy density 15% via thinner, safer barriers.

- Heavy Metallurgy — Kiln linings slash fuel 25%, extend reline intervals 40%. Baosteel pilot trials have demonstrated 12% emissions reductions with no spalling under 1,200°C cycles.

- Aerospace — Rocket nozzles resist 1500°C exhaust, reduce ablation 60% (NASA Artemis analogs and Chinese space station composites).

- Urban Fireproofing — High-rise coatings extend escape windows 45 min (NFPA simulations).

Woqin's Blueprint: From Lab Breakthrough to Industrial Impact

Hebei Woqin has scaled GT-mM-AZn since 2018: bespoke felts (180–220 kg/m³, up to 650°C), turnkey ecosystems (simulation, on-site audits, phased rollouts). Localized production + AI-optimized processes target ¥110/m² by 2026—competitive with rockwool yet 5× superior performance.

At the Frontier of High-Temp Resilience – Your Strategic Move?

GT-mM-AZn isn't just material—it's a strategic asset for industries facing heat, strength, and fire demands. Hebei Woqin stands ready as your strategic supply chain partner, delivering:

- Feasibility analysis with latest cost models to precisely evaluate project ROI.

- Tailored technical solutions for EV, metallurgy, aerospace, or fireproofing.

- Long-term stable supply + co-development for mutual growth.

Let's plan how your next high-temp challenge becomes your competitive edge.

Ruibin An

Hebei Woqin Trading Co., Ltd.

Phone/WhatsApp/WeChat: +86 139 3392 9092

Email: an@cn-aerogel.com

Website: insulatewool.com

Written by - Ruibin An

Industry Veteran with 13+ Years of Experience. Deeply rooted in the insulation industry for over 13 years, specializing in supply chain optimization and global market trends for Rock Wool and Aerogel materials.

LATEST NEWS

Don't Be Fooled by Reflective Paints: Why Your Industrial Roof Gets Hot Again in Year Two

2026-02-19

Stop the Bulk: How to Choose the Right "Core" for Removable Insulation Jackets? (Aerogel vs. Rockwool Real-World Comparison)

2026-02-16

The "Great Squeeze" of 2026: Why Your 90-Day Terms Are Putting 25-Year Assets at Risk

2026-02-14

Closing the 0.005 W/mK Gap: How EV Battery Tech Solved a Passive House Thermal Bridge Nightmare

2026-02-12

The 98% UK Retrofit Failure: The Vapor-Open Aerogel Fix (μ<5)

2026-02-09