Thinner Than Your Phone, Warmer Than −50°C: Aerogel Apparel – NASA Tech Meets Everyday Fashion

Imagine a jacket slimmer than your smartphone that laughs off −50°C Antarctic winds. Aerogel—"frozen smoke"—delivers NASA-grade insulation (0.020 W/(m·K), A1 fire-rated, 99.7% hydrophobic) in everyday apparel. Real tests show core temps stay 18°C at −30°C; brands like Supield and Bosideng prove it in extreme conditions. Hebei Woqin supplies the core aerogel blankets and particles powering this revolution—lighter, warmer, cleaner.

Thinner Than Your Phone, Warmer Than −50°C: Aerogel Apparel – NASA Tech Meets Everyday Fashion

Imagine slipping into a jacket slimmer than your smartphone, yet warm enough to laugh off a −50°C Antarctic gale. No bulky down puffers, no heavy synthetics—this is aerogel, the ethereal “frozen smoke” NASA perfected for Mars rovers. Once confined to space suits, aerogel is now strutting down city streets and catwalks, proving the coldest places on (and off) Earth can inspire the coziest, lightest fashion on Earth.

The Nano-Anatomy of Warmth: What Makes Aerogel Tick

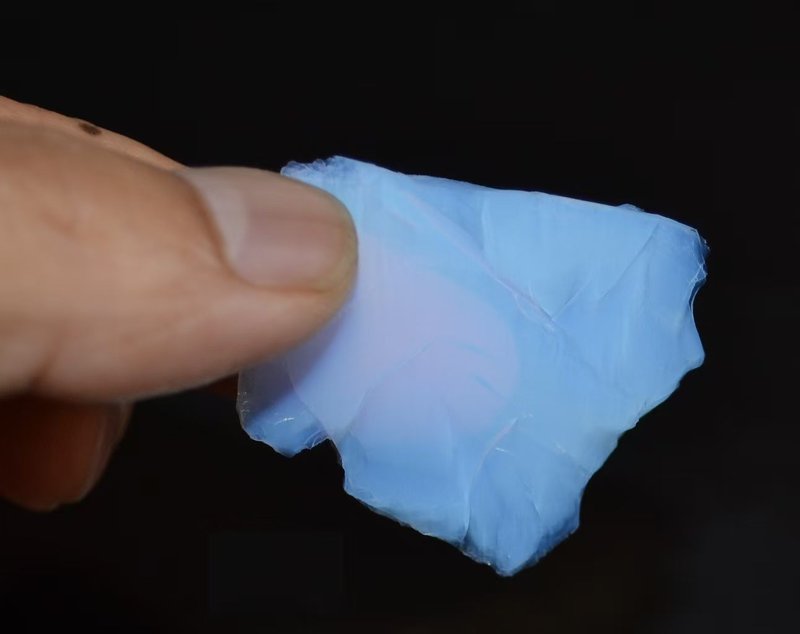

Aerogel isn’t fabric or foam—it’s a ghostly 3D lattice of silica strands just 2–5 nm thick, trapping air in cages smaller than air molecules’ mean free path. Heat conduction crashes to 0.020 W/(m·K) (Hebei Woqin blankets, GB/T 10295-2008)—37× lower than wool, 10× lower than premium goose down. Convection dies inside nanopores; radiation bounces off fractal walls—like putting handcuffs on heat, so it can’t escape. A 5 mm layer weighs just 80 g/m² yet matches 50 mm conventional fill.

NASA first deployed it on the 1997 Mars Pathfinder: lightweight enough to barely dent payload, yet robust against −90°C Martian nights. The same physics now keeps urban commuters toasty.

From Lab Curiosity to Flexible Textile: The Engineering Leap

Early aerogels shattered like sugar glass. 2025 breakthroughs changed everything—enabled by high-performance core materials from suppliers like Hebei Woqin, who scale the essential aerogel blankets and particles needed for these innovations:

- 3D-Printed Fiber Scaffolds: Templates weave aerogel into hollow, polar-bear-fur-like tubes—bendable without cracking.

- Supramolecular Crosslinking: Polyimide-aerogel hybrids compress 90% and spring back, eliminating “crunch.”

- Plasma-Enhanced Nano-Coating: 20 nm aerogel particles graft onto polyester/nylon via cold plasma—insulation without bulk.

These slashed production costs 70% since 2020, opening mass-market apparel.

Real Brands, Real Extremes: Performance You Can Measure

- Supield StarShell Pro (2025): Cold-chamber tests (−30°C, 5 m/s wind): Core temperature 18.1°C after 2 hours (down jacket: −8°C). Liquid nitrogen splash (−196°C): Surface frosted 3 seconds, interior unchanged (down froze brittle in 7 seconds). Breathability 8,500 g/m²/24h—sweat escapes, warmth stays.

- Bosideng Polar Expedition Series: Validated at China’s Zhongshan Antarctic Station (−52°C blizzard, 6 hours): Skin stayed 32.6°C. Weight 680 g full parka (vs. 1,800 g traditional). Durability: 100 wash cycles, zero insulation loss.

Third-party certification (SGS, Intertek) confirms no PFAS, no formaldehyde, 30-year projected lifespan.

Why Aerogel Crushes Every Legacy Fill

- Thermal Resistance: R-value per gram 15× higher than Primaloft, 8× higher than 900-fill down.

- Bidirectional Barrier: Keeps heat in winter, blocks solar gain in shoulder seasons.

- Hypoallergenic & Clean: No feathers, no mold, no VOCs—ideal for sensitive skin.

- Circular Potential: Silica aerogels recycle into new batches; carbon variants biodegrade under UV.

Tsinghua University 2025 LCA: Supield aerogel jacket offsets embodied carbon in 18 months vs 4 years for down.

The Cutting Edge: Solarcore and Beyond

Zhejiang University’s 2025 Solarcore prototype embeds phase-change microcapsules and aerogel into graphene-laced yarn: passive +5°C body-heat boost, active solar-powered micro-heaters for −70°C extremes, touchscreen sleeves, app-controlled warmth. Limited drop expected holiday 2026.

Hebei Woqin: The Core Power Behind Aerogel Apparel

Hebei Woqin Trading Co., Ltd. supplies the high-performance aerogel core materials powering this fashion revolution: blankets with 0.020 W/(m·K) conductivity, A1 non-combustible rating (1.9 MJ/kg combustion heat, 2°C furnace rise), 99.7% hydrophobic (GB/T 10299-2011), and particles at 715.82 m²/g surface area. EU-authorized (TOCYA TRADING, Paris, valid to Sep 2026), third-party verified (WT2024B01C01878 coatings, 24050192F blankets).

We don’t just supply materials—we empower brands with proven fabric-compatible solutions (enabling wash durability >100 cycles), thermal performance simulation to predict garment R-value before prototyping, and strict eco-supply chains that meet fashion’s toughest standards—turning NASA-grade tech into commercial success.

Your Next Winter Essential

Aerogel apparel isn’t gimmick—it’s aerospace rigor meeting everyday elegance. Lighter, warmer, cleaner, tougher: the future of staying warm has arrived, and it weighs less than your morning latte.

Ready to Partner or Experience It?For Brands & Designers: Start with a Development Kit

Take the first step without big commitments. Apply for our “Concept Development Support Pack”, including:

- Multi-spec material swatches for feel, cutting, and initial testing.

- Basic thermal simulation report tailored to your classic styles—predicting warmth gains with aerogel.

- 1-on-1 technical docking with our materials engineers to map design-to-production nodes.

For Consumers: Inquire about upcoming collections and where to buy.

Let’s define the next generation of functional fashion together.

Ruibin An

Hebei Woqin Trading Co., Ltd.

Phone/WhatsApp/WeChat: +86 139 3392 9092

Email: an@cn-aerogel.com

Website: insulatewool.com

Written by - Ruibin An

Industry Veteran with 13+ Years of Experience. Deeply rooted in the insulation industry for over 13 years, specializing in supply chain optimization and global market trends for Rock Wool and Aerogel materials.

LATEST NEWS

Don't Be Fooled by Reflective Paints: Why Your Industrial Roof Gets Hot Again in Year Two

2026-02-19

Stop the Bulk: How to Choose the Right "Core" for Removable Insulation Jackets? (Aerogel vs. Rockwool Real-World Comparison)

2026-02-16

The "Great Squeeze" of 2026: Why Your 90-Day Terms Are Putting 25-Year Assets at Risk

2026-02-14

Closing the 0.005 W/mK Gap: How EV Battery Tech Solved a Passive House Thermal Bridge Nightmare

2026-02-12

The 98% UK Retrofit Failure: The Vapor-Open Aerogel Fix (μ<5)

2026-02-09