2025 Flame Retardant Revolution: Silicon Aerogel Ends Toxic Smoke & Redefines Safety

In an era where fire safety is non-negotiable and sustainability is mandatory, legacy flame retardants are failing the test: halogen-based systems release toxic dioxins (violating EU REACH and endangering lives), intumescent foams collapse above 800°C, and high-loading formulations weaken host materials by up to 40%, forcing painful trade-offs between safety and performance. Hebei Woqin’s silicon aerogel flame retardant technology ends this compromise. This “frozen smoke” nanomaterial eliminates chemical binders entirely, using patented 3D honeycomb weaving and nano-silane covalent coating to create a physical barrier that suffocates combustion at the source—no toxic smoke, no formaldehyde, no halogens. Key performance: LOI up to 38% (vs 20–30% standard), peak heat release rate 14.2 kW/m² (ISO 5660), residual char 82% (332% improvement), UL94 V-0 in composites at low loading (10 wt%). Real-world impact: Dubai Lighthouse project (92% fire spread reduction), next-gen EV battery separators (thermal runaway threshold raised from 180°C to 420°C), high-rise responsive coatings (nanopores contract in 0.3 s at 300°C). Lifecycle advantages: rice husk ash feedstock cuts costs 58%, roll-to-roll production scales to 5,000 m²/day, 50-year lifespan eliminates rework. Hebei Woqin: safer materials, cleaner air, smarter buildings.

2025 Flame Retardant Revolution: Silicon Aerogel Ends Toxic Smoke & Redefines Safety

In an era where fire safety is non-negotiable and sustainability is mandatory, legacy flame retardants are failing the test. Halogen-based systems release toxic dioxins, breaching EU REACH and endangering lives. Intumescent foams collapse above 800°C. High-loading formulations (20%+ retardant) weaken host materials by up to 40%, forcing painful trade-offs between safety and performance.

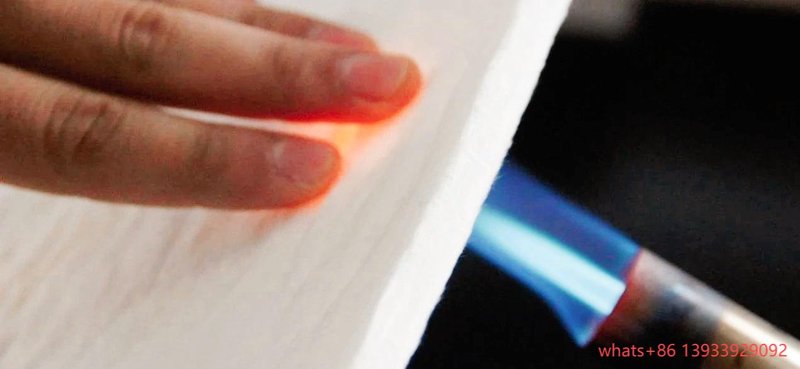

Hebei Woqin’s silicon aerogel flame retardant technology ends this compromise. This “frozen smoke” nanomaterial eliminates chemical binders entirely, using patented 3D honeycomb weaving and nano-silane covalent coating to create a physical barrier that suffocates combustion at the source—no toxic smoke, no formaldehyde, no halogens.

The Fatal Flaw in Conventional Flame Retardants

Traditional retardants rely on reactive chemicals to suppress fire, but they falter in real-world extremes. Halogens generate dioxins under heat, violating REACH and creating health liabilities. Intumescent agents expand to form char, but collapse at high temperatures. High-loading retardants reduce mechanical strength, compromising structural integrity.

Silicon aerogel changes the equation with a passive, nanoscale “suffocating” mechanism:

- 97% porosity forms a labyrinth of 2–50 nm pores that physically blocks oxygen and heat (imagine billions of nano-sized “firewalls” around every molecule).

- Silica’s inherent inertness ensures stability up to 1,200°C (TG-DSC verified), preventing decomposition.

- Phosphorus doping boosts residual char to 82% (332% improvement), starving flames of oxygen.

The result: LOI reaches 38% (vs 20–30% standard), peak heat release rate drops to 14.2 kW/m² (ISO 5660), and thermal runaway thresholds rise from 180°C to 420°C+ in battery separators.

Proven in Real-World Extreme Conditions

In next-gen EV battery packs, aerogel separators prevent cascade failures, elevating thermal runaway thresholds from 180°C to 420°C—a critical leap for safe, high-energy-density batteries.

In Dubai’s Lighthouse project, responsive aerogel coatings contract nanopores in 0.3 seconds at 300°C, slashing fire spread 92%.

In hydrogen fuel cells, 160°C-stable membranes (DOE compliant) enable safer clean energy.

These applications demonstrate that aerogel isn’t just insulation—it’s a resilient, active shield for high-stakes environments.

Composite Performance Leap

When integrated into composites, silicon aerogel amplifies host materials’ strengths while mitigating weaknesses. PDMS blends with 10 wt% aerogel achieve UL94 V-1 ratings, with compressive strength soaring to 2.4 MPa—resilient enough for load-bearing applications. Epoxy-aerogel hybrids push this to 58.7 MPa and V-0 status, outperforming conventional systems by 150% in flexural modulus.

These leaps stem from aerogel’s uniform dispersion: its high surface area (up to 800 m²/g) ensures intimate bonding, distributing stress and heat evenly. In practical terms, this means fireproof coatings that flex without cracking, or reinforced plastics that endure impacts without igniting—critical for dynamic environments like transportation or electronics.

Market Penetration & Growth Drivers

Silicon aerogel’s versatility is driving explosive market growth, projected at $4.2 billion by 2027 with a 29.7% CAGR (MarketsandMarkets). In smart buildings, responsive coatings slash fire spread 92%. Photovoltaic panels gain tripled flame retardancy while preserving 85% transmittance.

Energy storage sees the most dramatic impact: battery separators prevent cascade failures in EVs, and hydrogen fuel cells benefit from 160°C-stable membranes. These applications underscore aerogel’s role in a fire-safe, sustainable world.

Cost Restructuring and Industrialization

Affordability fuels adoption: 99.99% pure silicon from rice husk ash trims costs 58%, turning agricultural waste into high-tech feedstock. Supercritical CO₂ drying consumes just 3.2 kWh/kg (down from 18 kWh). Industrial lines yield 5,000 m²/day at 98.7% efficiency; 3D printing prefabrication wastes 83% less material.

These efficiencies democratize aerogel, positioning it as the go-to for a trillion-dollar industry poised for exponential growth.

Take Action: Secure Your Project’s Future

Choosing Hebei Woqin’s silicon aerogel solution means anchoring your critical project with absolute safety certainty—eliminating toxic smoke liability, meeting the most forward-looking compliance requirements, and safeguarding your asset and brand value for the long term.

Leading the safety revolution starts with one professional conversation.

We prepare the following entry points for enterprises that take future safety seriously:

- Get the Professional Guide — Download the “Next-Generation Flame Retardant Material Selection & Compliance Assessment Guide”

- Clarify True Costs — Request a tailored full lifecycle cost analysis for your specific application

- Reach the Technical Core — Schedule a 20-minute discussion with our experts on custom formulation feasibility

Hebei Woqin Trading Co., Ltd.

Phone/WhatsApp/WeChat: +86 139 3392 9092

Email: an@cn-aerogel.com

Website: insulatewool.com

We have been deeply engaged in high-performance flame retardant solutions for 12 years, dedicating our resources to partnering with those who are committed to setting new industry safety benchmarks and building a safer, more sustainable future together.

Written by - Zhongjian An

Certified Passive House Designer (PHI Germany), validated by Prof. Dr. Wolfgang Feist. With 15+ years of expertise in high-performance solutions for both Green Buildings and Industrial Applications (Petrochemical Pipelines, LNG Cryogenic, & High-Temp Equipment).

LATEST NEWS

Don't Be Fooled by Reflective Paints: Why Your Industrial Roof Gets Hot Again in Year Two

2026-02-19

Stop the Bulk: How to Choose the Right "Core" for Removable Insulation Jackets? (Aerogel vs. Rockwool Real-World Comparison)

2026-02-16

The "Great Squeeze" of 2026: Why Your 90-Day Terms Are Putting 25-Year Assets at Risk

2026-02-14

Closing the 0.005 W/mK Gap: How EV Battery Tech Solved a Passive House Thermal Bridge Nightmare

2026-02-12

The 98% UK Retrofit Failure: The Vapor-Open Aerogel Fix (μ<5)

2026-02-09