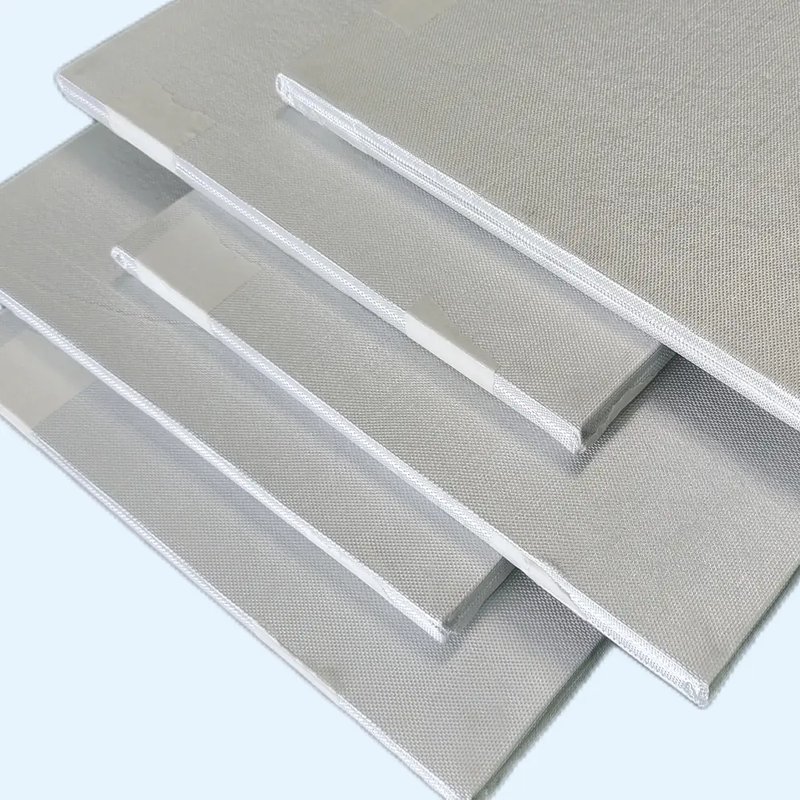

High-Performance Vacuum Insulation Panels (VIP) | Ultra-Thin STP Solutions by Woqin

PRODUCT INTRODUCTION

Hebei Woqin specializes in long-life STP Vacuum Insulation Panels. Featuring a fumed silica core and 9-layer barrier film, our panels achieve an ultra-low thermal conductivity of 0.002-0.008 W/(m·K). Ideal for German passive houses, cold chain logistics, and LNG tanks. A1 fire-rated with a 15+ year service life.

| Key Indicator | Requirement of Standard | Test Result | Conclusion |

| Appearance | No scratches/dents, well-sealed | Meet requirements | Conform |

| Thermal Conductivity (25℃) | ≤0.005W/(m·K) | 0.002W/(m·K) | Conform |

| Puncture Strength | ≥18N | 20N | Conform |

| Tensile Strength (Perpendicular to Panel) | ≥80kPa | 103kPa | Conform |

| Compressive Strength | ≥100kPa | 171kPa | Conform |

| Surface Water Absorption | ≤100g/㎡ | 79g/㎡ | Conform |

| Thermal Conductivity After Durability (25℃) | ≤0.005W/(m·K) | 0.002W/(m·K) | Conform |

| Combustion Performance (Class A2) - Furnace Temp Rise | ≤50℃ | 8℃ | Conform |

| Combustion Performance (Class A2) - Total Heat Release (600s) | ≤7.5MJ | 1.3MJ | Conform |

High-Performance Vacuum Insulation Panels (VIP) | Long-Life Glass Fiber Core

The Ultimate Space Saver: 20mm Replaces 120mm Foam

In the race for carbon neutrality, space is the ultimate luxury. Why waste 120mm of wall space on traditional foam when 20mm of Woqin VIP achieves the same thermal resistance? We utilize an advanced High-Density Glass Fiber Core protected by a 9-layer high-barrier film. Unlike inferior alternatives, our engineered "Getter System" absorbs residual gases, ensuring vacuum integrity and a stable service life of over 20 years.

Key Technical Data (Lab Certified):

- Thermal Conductivity: ≤ 0.002 W/(m·K) — The industry's lowest value; practically eliminates heat transfer.

- Service Life: 20+ Years — Advanced barrier technology ensures long-term vacuum retention.

- Compressive Strength: 171 kPa — High structural integrity for floor and wall integration.

- Fire Performance: Class A2 — Non-combustible core material.

- Temperature Range: Optimized for -120°C to +80°C (Absolute Max: 120°C).

Why This Matters for Your Project:

- Gain Floor Space: Perfect for German Passivhaus retrofits. Use 30mm VIPs in a 38mm buildup to meet energy codes without losing valuable interior square footage.

- Cold Chain Security: Maintains -70°C for 168 hours in vaccine shippers (proven in Qingdao medical logistics).

- Made-to-Measure Strategy: VIP panels cannot be cut on-site. We offer a full CAD Design Service, delivering pre-sized panels (L-shapes, U-shapes) for a perfect "Puzzle Fit" installation.

- Edge Protection: Optional Rubber Edge Tape or Fleece Wrapping protects the vacuum barrier during rough handling.

Applications:

- Architecture: Passivhaus Retrofits & Zero-Energy Buildings.

- Cold Chain: Vaccine Boxes & Medical Shippers.

- Industrial: LNG Spherical Tanks & Cryogenic Pipelines.

- Tech: High-Density Data Center Flooring (Shanghai Case Study).

⚠️ Operational Warning:

- Zero Cutting Rule: NEVER cut or drill a VIP panel on-site. Puncturing the barrier film destroys the vacuum immediately.

- Customization: We provide standard thicknesses (10mm - 50mm) and custom sizes up to 1200x600mm based on your drawings.

Fast Quote

Get a price for High-Performance Vacuum Insulation Panels (VIP) | Ultra-Thin STP Solutions by Woqin

CONTACT US

RELATED PRODUCTS

NEW

High-Purity Ceramic Fiber Needle Blanket | 1260°C Grade Refractory Insulation

Professional grade alumina-silicate fiber...

Ultra-High Strength Graphite EPS Insulation Sub-frame | 2090 kPa Compression Resistance

Engineered for extreme structural integrity,...

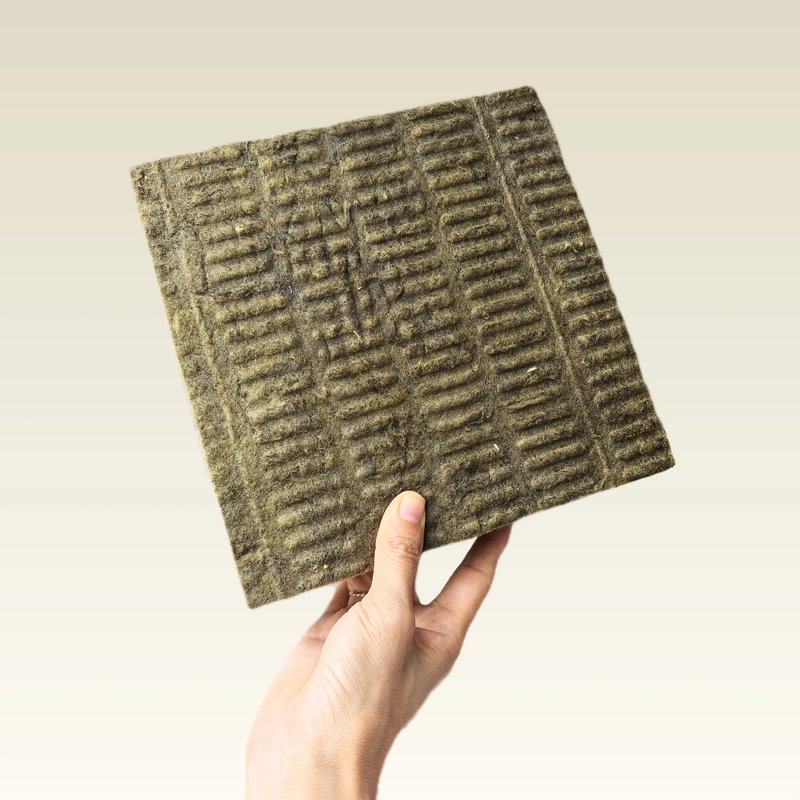

Premium Rock Wool Insulation Boards | Factory Direct Bulk Supply (A1 Fireproof)

Manufactured from high-purity basalt ore using...

RELATED PRODUCTS

High-Purity Ceramic Fiber Needle Blanket | 1260°C Grade Refractory Insulation

Professional grade alumina-silicate fiber blanket verified by Lab Report ....

Ultra-High Strength Graphite EPS Insulation Sub-frame | 2090 kPa Compression Resistance

Engineered for extreme structural integrity, our Graphite EPS Sub-frame...

Premium Rock Wool Insulation Boards | Factory Direct Bulk Supply (A1 Fireproof)

Manufactured from high-purity basalt ore using our advanced low-slag...