The Triesch House: When California Dreams Met Berlin Winters – Powered by Aerogel Felt

In Berlin’s Charlottenburg district stands a house that looks airlifted from the hills of Los Angeles: clean lines, warm mahogany cladding, floor-to-ceiling glass, and impossibly slender concrete columns. On a February morning at –12°C outside, the thermostat inside holds steady at 22°C with almost no heating required. The secret? Walls only 20 cm thick, insulated with Hebei Woqin’s high-performance aerogel felt. What traditionally required 40–60 cm of mineral wool or EPS to meet Germany’s passive-house standards now fits in half the thickness while delivering superior performance: U-value 0.18 W/(m²·K), extreme temperature stability −196°C to +650°C, A1 fire rating (GB 8624-2012), and 99.7% hydrophobicity (GB/T 10299-2011). The result: +4–6% usable floor area, heating demand reduced to 28–32 kWh/(m²·year) (half the Berlin average), and architectural elegance that never had to compromise energy efficiency. Hebei Woqin’s aerogel felt is proving that extreme performance and modernist lightness are no longer enemies — they are partners.

The Triesch House: When California Dreams Met Berlin Winters – Powered by Aerogel Felt

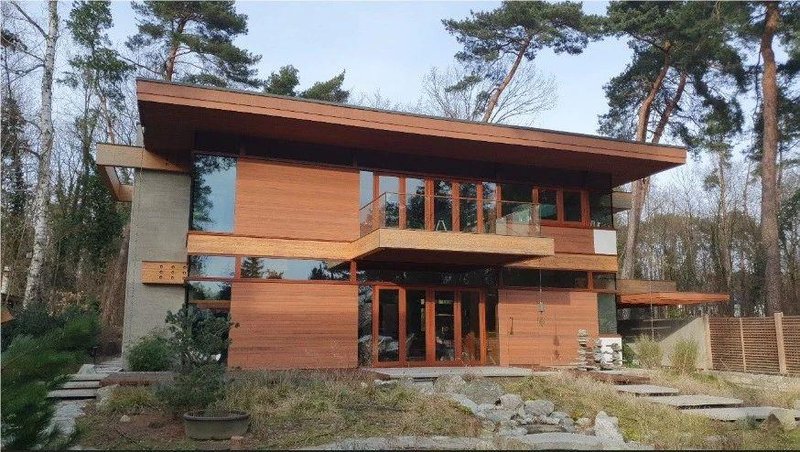

In the heart of Berlin’s Charlottenburg district stands a house that looks like it was airlifted straight from the hills of Los Angeles. Clean lines, warm mahogany cladding, floor-to-ceiling glass, and impossibly slender concrete columns. Yet on a February morning when the temperature outside is –12°C, the thermostat inside reads a steady 22°C – with almost no heating required.

The secret behind this small miracle? Walls that are only 20 cm thick, insulated with Hebei Woqin’s high-performance aerogel felt – the lightest solid material on Earth.

For decades, extreme energy efficiency meant one thing: thick walls. In Germany, a proper passive house often demands 40–60 cm of insulation. In northern China, it can reach 80 cm. The result? Lost interior space, deep window reveals, and a visual bulk that clashes with modernist ideals of lightness and openness.

Architect Lars Triesch refused to accept that compromise. Inspired by the post-and-beam masterpieces of California’s Case Study Houses and Ray Kappe’s floating structures, he wanted a Berlin home that felt airy and transparent – without freezing its occupants.

Aerogel felt made it possible.

How They Did ItThe Mahogany “Sandwich” Wall

A 15 cm laminated mahogany panel is wrapped around a 3–5 mm aerogel felt blanket on both sides. Total wall thickness: 20 cm.

Measured U-value: 0.18 W/(m²·K) – easily beating Germany’s strict passive-house requirement of ≤ 0.15 while looking like fine furniture from the outside.

Aerogel felt’s thermal conductivity of 0.020 W/(m·K) at 25°C (GB/T 10295-2008) and 99.7% hydrophobicity (GB/T 10299-2011) eliminate condensation risks and deliver performance that traditional materials simply cannot match in such thin layers.

Skinny Concrete Columns That Still Insulate

Structural columns were reduced from the usual 30–35 cm down to 18 cm by embedding a 5 mm aerogel felt core and reinforcing with carbon-fiber bars. The columns are stronger than traditional ones and eliminate thermal bridges completely.

Windows That Don’t Leak Heat

Aluminum window frames received aerogel-filled thermal breaks, dropping their conductivity from ~1.8 W/(m·K) to 0.8. Paired with triple low-E glazing and warm-edge spacers, the entire window assembly hits a U-value of 0.78 W/(m²·K).

A Roof That Breathes

Instead of thick PIR boards, the pitched roof was sprayed with 20 mm of aerogel coating under the metal standing-seam skin. No condensation, no heat loss, and 3°C cooler attic temperatures in summer.

Three years of monitored data tell the story: annual heating demand is 28–32 kWh/(m²·year) – roughly half the average for new Berlin homes of similar size. Interior usable floor area increased by 4–6% simply because the walls are thinner.

Beyond One House: Aerogel Felt Goes Mainstream

What was once a €300–400/m² exotic material used on Mars rovers and oil pipelines is now dropping below €150–180/m² thanks to ambient-pressure production breakthroughs by BASF, Cabot, Aspen Aerogels, and a wave of Chinese manufacturers including Hebei Woqin.

Prefabricated aerogel panels are now factory-made to ±1 mm tolerance, cutting on-site labor by 30–40%. Cities from Paris to Shenzhen are testing aerogel retrofits on historic façades that can’t be thickened externally – preserving architectural heritage while slashing energy bills 35–50%.

The Bigger Picture

Lars Triesch puts it simply while standing on his rooftop terrace overlooking Berlin’s snowy treetops:

“Aerogel didn’t just save energy. It gave me back the proportions I dreamed of. For the first time, extreme performance and architectural elegance aren’t enemies – they’re partners.”

In an era when buildings must become nearly zero-energy without turning into bulky bunkers, aerogel felt is proving that high performance doesn’t have to look heavy.

The future of sustainable architecture isn’t thicker walls. It’s smarter, thinner, lighter ones – and it’s already here.

Take Action: Bring Aerogel Felt to Your Project

Whether you are designing a passive house, retrofitting historic façades, or building next-generation energy-efficient structures, Hebei Woqin’s aerogel felt delivers unmatched thermal performance, fire safety, and design freedom.

Contact us today to:

- Download the “Aerogel Felt for Passive House & Modern Architecture Guide” (free).

- Request a tailored U-value and lifecycle cost analysis for your project.

- Schedule a 20-minute consultation with our architectural insulation specialists for custom solutions.

Ruibin An

Hebei Woqin Trading Co., Ltd.

Phone/WhatsApp/WeChat: +86 139 3392 9092

Email: an@cn-aerogel.com

Website: insulatewool.com

We specialize in advanced insulation solutions for 12 years. We partner with serious architectural and energy-efficiency projects that demand verifiable performance and true sustainability.

Written by - Ruibin An

Industry Veteran with 13+ Years of Experience. Deeply rooted in the insulation industry for over 13 years, specializing in supply chain optimization and global market trends for Rock Wool and Aerogel materials.

LATEST NEWS

Don't Be Fooled by Reflective Paints: Why Your Industrial Roof Gets Hot Again in Year Two

2026-02-19

Stop the Bulk: How to Choose the Right "Core" for Removable Insulation Jackets? (Aerogel vs. Rockwool Real-World Comparison)

2026-02-16

The "Great Squeeze" of 2026: Why Your 90-Day Terms Are Putting 25-Year Assets at Risk

2026-02-14

Closing the 0.005 W/mK Gap: How EV Battery Tech Solved a Passive House Thermal Bridge Nightmare

2026-02-12

The 98% UK Retrofit Failure: The Vapor-Open Aerogel Fix (μ<5)

2026-02-09