Stop the Silent Killer: Why Your Wall is Rotting at -20°C (And How WOqin Ends the "Phantom Ice" Crisis)

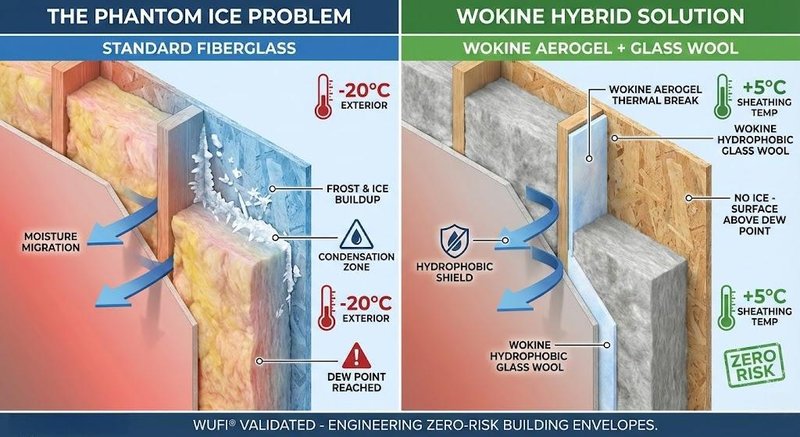

In the freezing depths of winter, traditional R-values are a dangerous illusion. Even with a sealed vapor barrier, "Phantom Ice" forms inside walls, silently compromising structural integrity and building value. This article reveals the fatal flaw of standard insulation in extreme climates and presents the Hebei woqin Hybrid Strategy—a WUFI® validated combination of Aerogel and High-Performance Glass Wool designed to keep structures bone-dry and energy-efficient.

The Nightmare Behind the Drywall

If any of these scenarios keep you up at night, this is for you:

- Your project is in a high-altitude or extreme cold region with long, brutal winters.

- You’ve invested in high-end vapor barriers but still fear hidden condensation.

- You are aiming for Passive House or Net-Zero certification and cannot afford a single performance gap.

The reality? At a 40°C temperature differential (+20°C inside / -20°C outside), standard insulation acts like a sponge. Industry-standard WUFI® Pro dynamic hygrothermal simulations prove that even with zero air leakage, moisture migrates and freezes on the cold OSB/sheathing surface. Standard building codes aren't protecting you; they are setting a timer for structural decay.

The Physics of Failure: Why Standard Fiber Fails

Traditional fibrous insulation (fiberglass/mineral wool) is effectively 95% air.

- Internal Convection: Huge temp differences drive air rotation within the material.

- Vapor Pressure Drive: Physics forces moisture toward the freezing outer shell.

- The Result: When vapor hits the frozen sheathing, it phase-changes into ice. Once it melts? Mold and Rot.

WOQIN: The "Risk-Control" Strategy

We don't just supply materials; we deliver Building Life-Cycle Insurance. Our hybrid system approaches the envelope as a precision-engineered shield.

1. The "Surgical" Strike: WOQIN Aerogel Blanket

Instead of thickening the whole wall, we use Aerogel to eliminate Critical Thermal Bridges.

- Extreme Performance: A staggering 0.020 W/m·K conductivity (ASTM C177).

- The Advantage: By applying 10mm Aerogel strips to studs and window headers, we keep surface temperatures above the dew point.

- Absolute Hydrophobicity: At >99.7%, it rejects moisture drive dead in its tracks.

2. The "Fortress" Core: WOQIN Ultra-High Grade Glass Wool

For bulk filling, we offer our proprietary hydrophobic board (WOQIN Verified Data):

- Superior Conductivity: 0.034 W/m·K (@ 25°C). While competitors stay at 0.040+, WOQIN offers a 15% efficiency boost.

- Low Moisture Content: With moisture content ≤1.0% and specialized fiber alignment (fiber diameter ≤7.0μm), we minimize the internal convection that causes "Phantom Ice."

- Safety: A1 Non-combustible rating for ultimate fire protection.

Quantified Evidence: The WUFI® Simulation

In a 30-day extreme cold simulation (-20°C external), wall assemblies using the WOQIN Hybrid System maintained the internal OSB surface temperature at +5.2°C—safely above the -2.1°C dew point.

- The Result: Zero frost. Zero condensation.

- The Value: Up to 30% longer lifespan for the building envelope and 15% reduction in annual heating costs compared to standard layouts.

[The Next Step: Map Your Risk]

Building for the future requires mastering physics, not just meeting a code.

Are you designing a project in a high-risk climate? Don't leave your structural integrity to chance. Submit your wall section drawings today, and our technical team will provide a:

Free Condensation Risk Simulation (Dew Point Analysis)

We will map the temperature and vapor pressure gradients across your specific assembly using industry-standard modeling. Get a tailored material configuration that guarantees a zero-risk building envelope.

WOKINE – Engineering Zero-Risk Building Envelopes.

[Contact Us to Start Your Simulation Request a Technical Sample Pack]

Written by - Zhongjian An

Certified Passive House Designer (PHI Germany), validated by Prof. Dr. Wolfgang Feist. With 15+ years of expertise in high-performance solutions for both Green Buildings and Industrial Applications (Petrochemical Pipelines, LNG Cryogenic, & High-Temp Equipment).

LATEST NEWS

Stop the Silent Killer: Why Your Wall is Rotting at -20°C (And How WOqin Ends the "Phantom Ice" Crisis)

2026-02-04

Industrial Pipe Insulation: A Strategic Selection Framework Based on Thermal Risk & Asset Integrity

2026-02-03

The 80/20 Engineering Strategy: Solving the Critical 20% of Structural Thermal Bridges for Total Envelope Integrity

2026-02-01

Beyond Logistics: Why 8.115MPa PU & High-Mk Rock Wool is the Only "Risk-Hedged" Solution for Middle East Coastal EPCs

2026-02-01

The Hidden $50k Cost in Your Insulation Bid: Why Thermal Integrity Beats Price Per Meter

2026-01-31