STP Vacuum Insulation Panels: Ultra-Thin, Ultra-Efficient – Redefining Insulation for Modern Architecture

In high-density urban construction, every centimeter of wall thickness translates to lost usable space and higher costs. Traditional insulation forces architects and developers into a painful trade-off: thick walls for energy efficiency or thin walls at the expense of performance. Hebei Woqin’s STP (Super Thermal Performance) vacuum insulation panels eliminate that compromise. By applying aerospace-grade vacuum technology to civil construction, STP achieves an industry-leading thermal conductivity of 0.002–0.008 W/(m·K) — outperforming air itself — while maintaining A1 fireproof certification and decades of stable performance. Key performance (verified by third-party testing): 1 cm STP equals 3 cm rock wool or 5 cm polyurethane Compressive strength ≥0.2 MPa, tensile ≥0.1 MPa Vacuum maintained <1 mbar over 60 years (seven-layer barrier + 25 g getter) Weight reduction 70%, usable space gain 5–10% per building Annual heating demand as low as 15 kWh/(m²·year) in Munich passive houses Cold-chain logistics: −18°C maintained for 120 hours in 35°C ambient (8× better than EPS) From landmark high-rises in Qingdao to prefabricated systems in Xiong’an and COVID-19 vaccine cold-chain transport, STP panels deliver safety, efficiency, and sustainability without bulk.

STP Vacuum Insulation Panels: Ultra-Thin, Ultra-Efficient – Redefining Insulation for Modern Architecture

STP Vacuum Insulation Panels: Ultra-Thin, Ultra-Efficient – Redefining Insulation for Modern Architecture

In high-density urban construction, every centimeter of wall thickness translates to lost usable space and higher costs. Traditional insulation forces architects and developers into a painful trade-off: thick walls for energy efficiency or thin walls at the expense of performance.

Hebei Woqin’s STP (Super Thermal Performance) vacuum insulation panels eliminate that compromise. The result of 16 years of R&D, STP translates aerospace-grade vacuum technology into practical solutions for civil buildings, enabling ultra-thin, ultra-efficient, and aesthetically lightweight insulation systems.

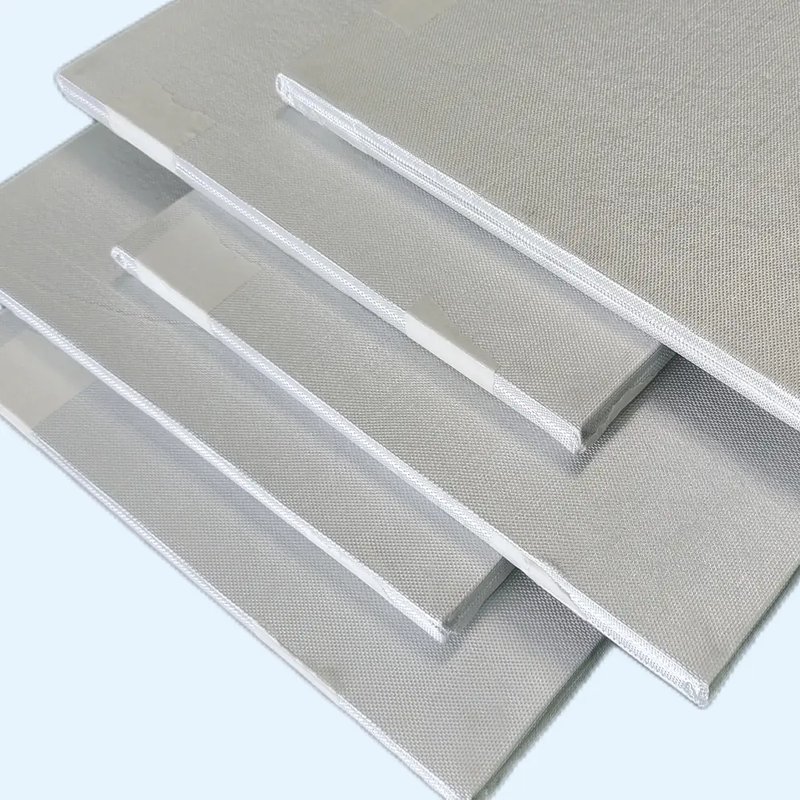

Unlike traditional materials that rely on porous bulk to delay heat flow, STP panels use vacuum pumping to remove air down to <0.02 Pa, creating a nanoscale vacuum cavity that blocks convection entirely. The silica aerogel-based composite core achieves an industry-low thermal conductivity of 0.002–0.008 W/(m·K) — outperforming air itself. A single 1 cm STP board equals 3 cm of rock wool or 5 cm of polyurethane, freeing 5–10% of indoor space — a game-changer for high-density urban buildings.

Five Core Performance Features: Redefining the Standards for Insulation Materials

- Extreme Insulation Across Temperature Extremes

In a Munich passive house project, a 2 cm STP board endured −15°C, achieving energy use of just 15 kWh/(m²·year) — one-tenth that of conventional buildings. Its vacuum structure excels from LNG tanks at −200°C to industrial furnaces at 600°C, maintaining A1 fireproof certification without emitting toxic gases. - Lightweight, Thin, Yet Structurally Resilient

At the 237 m Qingdao China Railway Center, 15 mm STP panels replaced 80 mm rock wool, cutting wall weight by 70% and increasing curtain wall glass by 20%. With compressive strength ≥0.2 MPa and tensile ≥0.1 MPa, it withstands typhoon-level winds and exceeds national pressure resistance standards by 3×. - Decades of Stable Performance

Data from Wolfurt, Austria shows just 3% vacuum loss and <5% conductivity increase after 30 years. Its seven-layer composite barrier—with aluminum foil, fiberglass mesh, and nano-coating—combined with a 25 g getter, maintains vacuum below 1 mbar over 60 years. - Environmentally Sustainable Composition

The STP core uses 70% microsilica waste and emits no Freon. VOC emissions are reduced by 80% thanks to formaldehyde-free bonding, supporting LEED and China's green building certifications. - Versatile Applications Beyond Buildings

In logistics, Woqin’s VIP boxes preserve −18°C for 120 hours in 35°C weather — 8× better than EPS. In Tesla’s battery plant, STP boards endure thermal shocks from 200°C to −40°C. Flexible variants wrap complex industrial shapes, with water repellency ≥99%.

Full-Scenario Applications: From Landmark Buildings to People’s Livelihood Projects1. Building Energy Conservation

At Beijing New Children's Palace, STP boards were integrated with photovoltaic glass to create “insulation + generation + decor” facades. Winter heating dropped 47%, cooling load fell 35%, and total energy efficiency rose 60%. In dense cities, STP unlocks 50–100 m² of usable space per building and improves ROI by 30%.

2. Prefabricated Buildings

A collaboration with Tongji University produced a reverse-casting panel system that removes connectors and outer layers. Wall thickness dropped from 20 cm to 12 cm, weight by 40 kg/m², and cost by 150 yuan/m². It passed 8-grade seismic tests in Xiong’an and reduced construction time by 40%.

3. Industrial Thermal Protection

In Jinan Steel’s blast furnaces, STP panels halved heat loss, cut surface pipe temps from 60°C to 30°C, and prevented worker burns. Their salt-spray resistance doubles lifespan and cuts maintenance by 50%.

4. Cold Chain Logistics

During COVID-19 vaccine transport, STP medical boxes achieved ±0.5°C accuracy. Location tracking has <50 m error, and fresh e-commerce companies reported loss rate drops from 8% to 1.2%. Each box is reusable 500 times, cutting emissions by 70%.

Technical Barriers: A Patent Matrix Guarding the Quality Bottom Line

Woqin’s advantage lies in deep-tech mastery across materials, processes, and engineering. Its seven-layer gas barrier film passes ASTM E96, with vapor transmission <0.1 g/(m²·24h) — 20× better than standard foil.

Its automated factory ensures <0.5% core filling error, 0.01 Pa pressure control, and 1000-fold bend and helium leak tests for zero-defect delivery. As a designated material by the China Academy of Building Research, Woqin has helped draft ISO 16478, bringing Chinese standards global.

The Future is Here: When Buildings Start “Self-Insulating”

Woqin’s roadmap includes smart STP panels with embedded nanosensors. These monitor wall conditions and adjust vacuum valves for humidity control and thermal optimization. Integration with BIM systems enables full digital workflows, shortening project time by 25%.

In Xiong’an’s carbon-neutral zone, STP panels work with ground-source heat pumps and ventilation to achieve “zero-carbon heating,” where solar output offsets winter energy use. These systems transform buildings from energy consumers to energy balancers — redefining their role in sustainable ecosystems.

Conclusion

Hebei Woqin’s STP vacuum insulation panel is the perfect marriage of material science and architectural evolution. It proves that buildings can be safer without bulk, greener without compromise, and smarter without complexity. From Europe’s Alps to China’s megacities, in temperatures from −200°C to 600°C, Woqin’s nanotech guardian is shielding structures while advancing civilization.

This isn’t just another product — it’s a redefinition of how humans live with, build upon, and protect the environment. Through each embedded panel, we move closer to a future where every building is a resilient, efficient, and harmonious part of the planet.

Take Action: Secure Your Project’s Future

Don’t let legacy insulation limit your next high-efficiency building. Hebei Woqin’s STP vacuum insulation panels deliver unmatched thermal performance, fire safety, and space savings.

Contact us today to:

- Download the “STP Vacuum Insulation Panels Technical Guide” (free).

- Request a tailored U-value calculation and lifecycle cost analysis for your project.

- Schedule a 20-minute consultation with our insulation specialists for custom solutions.

Hebei Woqin Trading Co., Ltd.

Phone/WhatsApp/WeChat: +86 139 3392 9092

Email: an@cn-aerogel.com

Website: insulatewool.com

We specialize in advanced insulation solutions for 12 years. We partner with serious architectural, industrial, and energy projects that demand verifiable performance and true sustainability.

Written by - Zhongjian An

Certified Passive House Designer (PHI Germany), validated by Prof. Dr. Wolfgang Feist. With 15+ years of expertise in high-performance solutions for both Green Buildings and Industrial Applications (Petrochemical Pipelines, LNG Cryogenic, & High-Temp Equipment).

LATEST NEWS

If the Tang Dynasty Had VIPs: Why Modern Luxury Food Delivery Needs "Vaccine-Grade" Protection

2026-02-05

Stop the Silent Killer: Why Your Wall is Rotting at -20°C (And How WOqin Ends the "Phantom Ice" Crisis)

2026-02-04

Industrial Pipe Insulation: A Strategic Selection Framework Based on Thermal Risk & Asset Integrity

2026-02-03

The 80/20 Engineering Strategy: Solving the Critical 20% of Structural Thermal Bridges for Total Envelope Integrity

2026-02-01

Beyond Logistics: Why 8.115MPa PU & High-Mk Rock Wool is the Only "Risk-Hedged" Solution for Middle East Coastal EPCs

2026-02-01