Catalog Overview of Foam Board Insulation Products for Industrial and Civil Applications

Energy efficiency has become a top priority for both industrial facilities and residential homes, making the selection of the right materials crucial.

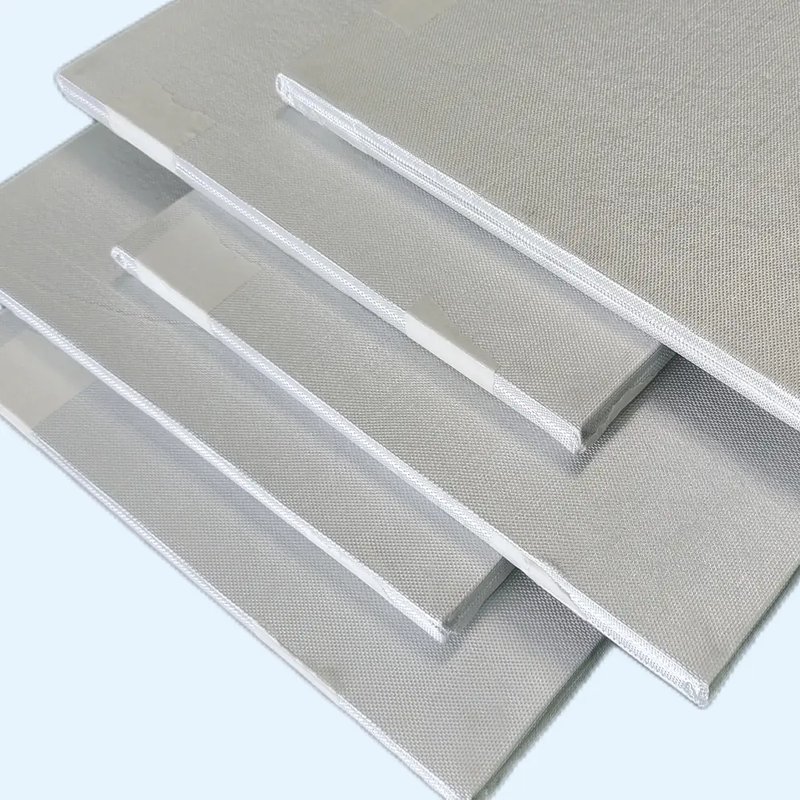

Energy efficiency has become a top priority for both industrial facilities and residential homes, making the selection of the right materials crucial. In the competitive thermal insulation material market, InsulateWool Polyurethane Foam Board emerges as a leading solution. This advanced thermal insulation is crafted from high-density rigid polyurethane foam, offering a balance of functionality, durability, and energy efficiency. Its closed-cell structure is designed to meet the demands of diverse construction projects, from massive industrial buildings to quiet residential spaces, providing consistent performance.

Table of contents:

Differentiating polyurethane foam insulation board features across multiple size options

The significance of dimensional tolerance and thermal conductivity in product selection

Application categories spanning from steel structure insulation to soundproofing layers

Differentiating polyurethane foam insulation board features across multiple size options

Project specifications rarely follow a one-size-fits-all model, which is why a leading polyurethane insulation board manufacturer offers a wide array of options. The InsulateWool Polyurethane Foam Board is available in numerous standard sizes, ranging from small 100x100x50mm blocks to large 600x600x300mm panels. This versatility allows architects and builders to select the appropriate dimensions without wasteful cutting on-site. For more specialized projects, custom cutting services ensure that every piece fits precisely, whether for intricate curtain wall supports or unique passive room pads. Furthermore, the option for embedded anchor holes simplifies the installation process, saving time and labor costs. The variety extends to mechanical properties as well, with compressive strengths spanning from 350psi for lighter load applications to a robust 2100psi for areas requiring significant structural support. This adaptability is what sets a quality product apart in the thermal insulation material market, ensuring that each application receives a solution tailored to its specific structural and thermal demands, demonstrating the commitment of a reliable polyurethane insulation board manufacturer.

The significance of dimensional tolerance and thermal conductivity in product selection

Two technical details often determine a project's long-term success: dimensional tolerance and thermal conductivity. For a product like the InsulateWool board, a thermal conductivity value of ≤ 0.080 W/mK is a critical indicator of its insulating power. This low value, achieved through a high-density, closed-cell polyurethane foam structure, means less heat transfer and greater energy savings. In applications like cold storage or cryogenic environments, maintaining a stable temperature is non-negotiable. The product’s broad working temperature range, from -196°C to +120°C, makes it suitable for these extreme conditions. Equally important is the dimensional tolerance of ±1mm. A trusted polyurethane insulation board manufacturer ensures this precision, which prevents gaps between panels that could create thermal bridges and compromise the entire insulation system. This attention to detail, combined with low water absorption of ≤3% and minimal moisture permeability, guarantees consistent performance over a 30+ year service life, a key differentiator in the crowded thermal insulation material market.

Application categories spanning from steel structure insulation to soundproofing layers

Modern insulation materials prove their value by adapting to diverse construction challenges. The InsulateWool Polyurethane Foam Board exemplifies this with its wide range of applications. In industrial settings, it serves as an effective insulator for steel structures and as a structural support for curtain walls, preventing thermal bridging and enhancing building envelope performance. Its high compressive strength makes it an ideal choice for passive room pads, providing a stable and insulated foundation. For the food and pharmaceutical industries, it is a primary choice for cold storage insulation layers. Moving into civil and residential construction, its utility continues. It acts as an efficient barrier in floor heating systems and roofing assemblies, minimizing energy loss. Furthermore, its dense structure provides acoustic benefits, capable of delivering up to 35dB in noise reduction, making it a functional soundproofing layer for apartments and offices. A responsible polyurethane insulation board manufacturer also ensures the product is environmentally sound, with EU RoHS compliance and a Freon-free production process. With a standard B1 fire retardant rating and an optional A2 fireproof version, it meets stringent safety codes for a variety of uses.

Navigating the thermal insulation material market requires focusing on materials that deliver tangible performance across multiple metrics. From its impressively low thermal conductivity to its broad application range, the InsulateWool board stands out as a reliable and efficient choice. A dedicated polyurethane insulation board manufacturer can provide tailored solutions, including wholesale and OEM options, to meet the specific needs of any project. Choosing a solution built on a high-density, closed-cell structure ensures lasting energy efficiency and structural integrity for the future.

Contact Us: Hebei Woqin Trade Co., Ltd.

- Phone/WhatsApp: +86 13933929092

- Email: an@cn-aerogel.com

- Website: www.insulatewool.com

Written by - Ruibin An

Industry Veteran with 13+ Years of Experience. Deeply rooted in the insulation industry for over 13 years, specializing in supply chain optimization and global market trends for Rock Wool and Aerogel materials.

LATEST NEWS

Precision-Cut Aerogel: The One-Day Solution for UK Retrofit Experts

2026-01-25

Zero-Risk Fire Safety: Bulk High-Density Rock Wool for Mega Power Infrastructure – A1 Rated & Container-Ready

2026-01-21

The "Performance Decay" Trap: Why Your Building’s R-Value is Lower Than You Think

2026-01-20

Beyond Support: Why 8.11 MPa HDPU is the New ISO Standard for Cryogenic Pipe Supports & Heavy Loads

2026-01-20

Stop Thermal Bridges at the Source: High-Strength PU Structural Thermal Breaks (600 kg/m³)

2026-01-19