Navigating Polyurethane Insulation Board Product Lines for Targeted Construction Uses

Selecting the right insulation is a critical decision that impacts energy efficiency, structural integrity, and long-term performance in today's complex construction landscape.

Selecting the right insulation is a critical decision that impacts energy efficiency, structural integrity, and long-term performance in today's complex construction landscape. As architects and builders navigate the vast thermal insulation material market, finding a single solution that adapts to varied demands can be challenging. The InsulateWool Polyurethane Foam Board emerges as an advanced thermal insulation solution, engineered from high-density rigid polyurethane foam. It offers a balanced approach for projects ranging from industrial facilities to residential buildings, streamlining the specification process with its versatile and durable properties.

Table of contents:

Size ranges and tailor-made cutting services meeting diverse project requirements

Environmental compliance and green production processes influencing board selection

Matching compressive strength grades to specific structural or passive room pad needs

Size ranges and tailor-made cutting services meeting diverse project requirements

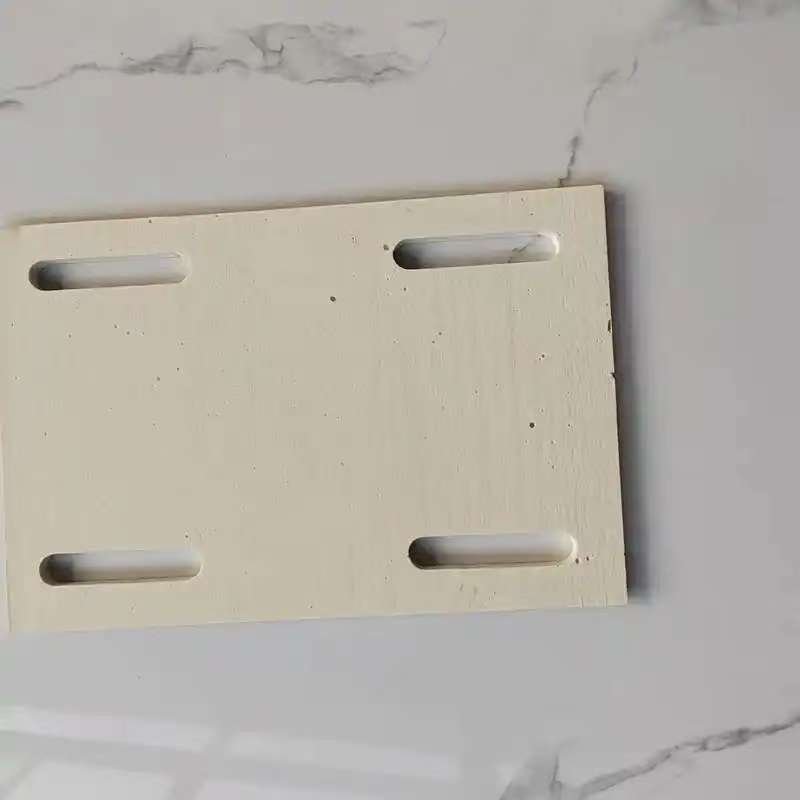

Modern architectural designs often feature unique dimensions that require precise and clean insulation installation to avoid thermal bridges, which compromise energy efficiency. A forward-thinking polyurethane insulation board manufacturer addresses this challenge directly by offering extensive customization. While standard sizes ranging from 100x100x50mm up to 600x600x300mm are readily available, the true value lies in tailor-made cutting services. These services allow contractors to specify exact dimensions for a perfect fit, significantly reducing on-site labor and material waste. Furthermore, options for embedded anchor holes streamline the installation process for applications like steel structure insulation and curtain wall supports. This level of precision is supported by a tight dimensional tolerance of ±1mm, ensuring that each board aligns seamlessly with the next. This capability creates a continuous, high-performance insulation layer that is difficult to achieve with materials less suited to precise fabrication, providing a distinct advantage for complex industrial and commercial building envelopes.

Environmental compliance and green production processes influencing board selection

Sustainability now stands as a core pillar of modern construction, significantly evolving the criteria for selecting building materials. Specifiers are increasingly influenced by environmental regulations and a growing client demand for eco-conscious buildings. In this context, the composition and manufacturing process of insulation boards are under greater scrutiny. The InsulateWool Polyurethane Foam Board is produced with a green production process that is entirely free of Freon components, aligning with global efforts to protect the ozone layer. Furthermore, it meets strict environmental standards, including EU RoHS compliance, which restricts the use of specific hazardous substances. A reputable polyurethane insulation board manufacturer who prioritizes these green credentials provides assurance that the material contributes to a healthier indoor environment and a building’s overall sustainability profile. This commitment also extends to longevity; with a service life of over 30 years and an optional A2 fireproof version, the board minimizes the need for replacements, reducing long-term environmental impact and making it a responsible choice in a competitive thermal insulation material market.

Matching compressive strength grades to specific structural or passive room pad needs

Many applications require insulation materials that offer robust structural capacity alongside thermal properties. For load-bearing scenarios, such as industrial flooring, cold storage facilities, or passive room pads that support heavy equipment or structural elements, the material’s compressive strength is non-negotiable. Unlike traditional options such as EPS foam, which may not offer sufficient resistance to crushing, high-density polyurethane boards provide superior performance. A leading polyurethane insulation board manufacturer offers a wide spectrum of compressive strength grades, from 350psi to an impressive 2100psi. This allows engineers to match the board's specification precisely to the application's demands. For example, a lower grade may be suitable for roofing, while a high-strength board is essential for a passive room pad in an industrial setting. This structural integrity is complemented by other robust properties, including extremely low water absorption of 3% or less and a broad working temperature range from -196°C to +120°C, making it a reliable choice for the demanding environments found in the cold chain industry and heavy manufacturing. This versatility distinguishes it within the thermal insulation material market.

Choosing the right insulation involves looking beyond a single metric and considering a product's holistic performance. The ability to specify custom sizes, verify environmental compliance, and select the appropriate compressive strength simplifies decision-making across diverse construction projects. Navigating the thermal insulation material market becomes more straightforward when a solution offers consistent, high-level performance across multiple criteria. The InsulateWool board’s low thermal conductivity of ≤ 0.080 W/mK ensures superior energy savings. For those seeking a reliable partner, a polyurethane insulation board manufacturer focused on quality and customization can help ensure every project achieves its functional and efficiency goals.

LATEST NEWS

Precision-Cut Aerogel: The One-Day Solution for UK Retrofit Experts

2026-01-25

Zero-Risk Fire Safety: Bulk High-Density Rock Wool for Mega Power Infrastructure – A1 Rated & Container-Ready

2026-01-21

The "Performance Decay" Trap: Why Your Building’s R-Value is Lower Than You Think

2026-01-20

Beyond Support: Why 8.11 MPa HDPU is the New ISO Standard for Cryogenic Pipe Supports & Heavy Loads

2026-01-20

Stop Thermal Bridges at the Source: High-Strength PU Structural Thermal Breaks (600 kg/m³)

2026-01-19