Polyurethane Foam Insulation Board Supplier Selection Criteria and Product Choices

Energy efficiency dominates the priorities of modern construction, increasing the pressure to select the right insulation materials.

Energy efficiency dominates the priorities of modern construction, increasing the pressure to select the right insulation materials. The crowded thermal insulation material market presents a challenge, making it difficult to distinguish between suppliers. For projects demanding high performance, the InsulateWool Polyurethane Foam Board emerges as an advanced solution. This material, made from high-density rigid polyurethane foam, provides a superior balance of functionality and energy savings for industrial, commercial, and residential applications, setting a high standard for building envelopes.

Table of contents:

Assessing production standards such as EU RoHS compliance for supplier verification

Comparing board density options and associated thermal insulation benefits

Importance of customizable anchor holes and cutting precision for client specifications

Assessing production standards such as EU RoHS compliance for supplier verification

Choosing a polyurethane insulation board manufacturer begins with verifying their commitment to international production standards. Certifications are not just logos on a datasheet; they are proof of a supplier's dedication to safety, quality, and environmental responsibility. For instance, compliance with EU RoHS directives ensures that the product is free from specific hazardous substances, making it safer for both installers and building occupants. A reputable manufacturer will embrace a green production process, such as one that is completely free of Freon components, minimizing environmental impact. The InsulateWool Polyurethane Foam Board meets these stringent EU RoHS standards. Furthermore, production quality directly translates to performance attributes like fire safety, with options for a B1 fire retardant rating or an optional A2 fireproof version, and durability, as evidenced by a service life of over 30 years. These factors demonstrate that the manufacturer invests in long-term reliability, which is a key indicator of a trustworthy partner for any construction p roject, from residential soundproofing to large-scale industrial insulation.

Comparing board density options and associated thermal insulation benefits

Evaluating the technical specifications of the insulation boards themselves is vital, particularly board density and its effect on thermal performance. A higher density often corresponds to greater compressive strength and improved insulation capabilities. The thermal insulation material market offers many choices, but high-density rigid polyurethane foam provides a distinct advantage. The InsulateWool Polyurethane Foam Board features a customizable density, with a standard of 600kg/m³, and a closed-cell structure that delivers a low thermal conductivity of ≤ 0.080 W/mK. While offering superior compressive strength compared to rock wool, it maintains excellent thermal resistance compared to traditional structural materials like concrete or timber. Moreover, it boasts a much higher compressive strength than EPS foam, with options ranging from 350psi to 2100psi. For project managers and engineers, this means the material can be used in demanding applications like cold storage flooring, steel structure supports, and passive room pads where both structural integrity and thermal efficiency are required. A skilled polyurethane insulation board manufacturer will offer this range to ensure the product precisely matches the project's load-bearing and insulation needs.

Importance of customizable anchor holes and cutting precision for client specifications

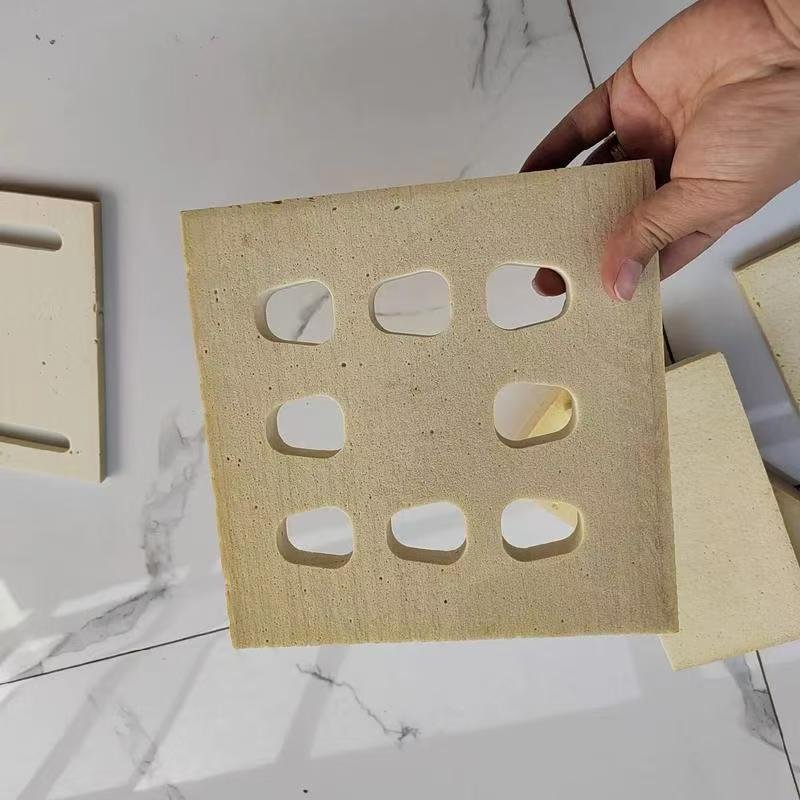

Meeting unique client specifications through customization is a critical factor for suppliers. Standard-sized panels are rarely a perfect fit for complex architectural designs, leading to significant on-site modifications, material waste, and increased labor costs. A forward-thinking polyurethane insulation board manufacturer addresses this by offering precise customization services. For example, the InsulateWool Polyurethane Foam Board is available in various standard sizes, but it can also be custom-cut to exact dimensions with a tight tolerance of ±1mm. This precision ensures a seamless fit, which is critical for applications like curtain wall supports and floor heating insulation. Additionally, the option for embedded anchor holes simplifies the installation process, securing the boards firmly and reducing a major step for construction crews. This level of customization demonstrates a manufacturer's client-centric approach, transforming a simple material supply into a partnership that adds tangible value by saving time and resources on the job site.

Choosing the right supplier in the dynamic thermal insulation material market requires a holistic evaluation of production standards, technical performance, and customization capabilities. By prioritizing these criteria, contractors and developers can secure materials that not only meet but exceed project requirements. The InsulateWool Polyurethane Foam Board, with its low water absorption of ≤3% and broad working temperature range, exemplifies the quality that comes from a dedicated polyurethane insulation board manufacturer. Partnering with a brand that offers OEM and wholesale opportunities ensures access to consistently high-quality products for all future builds.

Contact Us: Hebei Woqin Trade Co., Ltd.

- Phone/WhatsApp: +86 13933929092

- Email: an@cn-aerogel.com

- Website: www.insulatewool.com

Written by - Ruibin An

Industry Veteran with 13+ Years of Experience. Deeply rooted in the insulation industry for over 13 years, specializing in supply chain optimization and global market trends for Rock Wool and Aerogel materials.

LATEST NEWS

Precision-Cut Aerogel: The One-Day Solution for UK Retrofit Experts

2026-01-25

Zero-Risk Fire Safety: Bulk High-Density Rock Wool for Mega Power Infrastructure – A1 Rated & Container-Ready

2026-01-21

The "Performance Decay" Trap: Why Your Building’s R-Value is Lower Than You Think

2026-01-20

Beyond Support: Why 8.11 MPa HDPU is the New ISO Standard for Cryogenic Pipe Supports & Heavy Loads

2026-01-20

Stop Thermal Bridges at the Source: High-Strength PU Structural Thermal Breaks (600 kg/m³)

2026-01-19