Zero-Risk Fire Safety: Bulk High-Density Rock Wool for Mega Power Infrastructure – A1 Rated & Container-Ready

For EPC contractors, fire safety is about passing rigorous audits on time and under budget. A single failed fire-stop inspection can delay a multi-million dollar substation project. Hebei Woqin provides factory-direct, high-density Rock Wool that ensures your cable tunnels pass inspection the first time, every time.

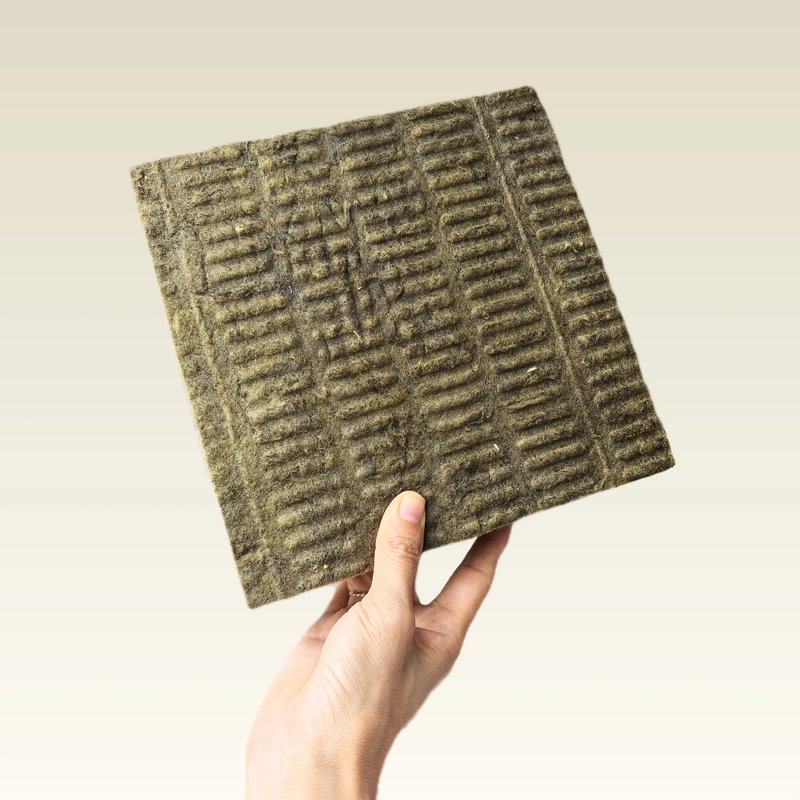

1. Standing Firm in the Flame: Stopping the "Chimney Effect" In a fire, vertical cable shafts act like chimneys, spreading flames across floors in seconds. Your fire-stopping material must do more than just "not burn"—it must remain structurally intact. While standard mineral wool may degrade quickly, Woqin High-Density Rock Wool is engineered to withstand constant service temperatures up to 600°C, with a core melting point exceeding 1000°C. Our specialized fire-stop slabs can provide a critical fire-resistance rating of up to 1.5 hours, ensuring the "Chimney Effect" is cut off at the source before the integrity of the building is compromised.

To stop this, your fire-stopping material must do more than just "not burn." Many materials are classified as "non-combustible" but crumble or melt when exposed to the sustained, intense heat of an industrial fire. At Hebei Woqin, we emphasize Mechanical Integrity under Thermal Stress. Our high-density Rock Wool is engineered with a melting point exceeding 600°.

When a flashover occurs, Woqin Rock Wool remains sound and structurally intact. It maintains its physical shape even under the standard ISO 834 fire curve, creating a rigid thermal barrier that physically cuts off the air supply to the fire and blocks the "Chimney Effect" at the source. By preserving its density and volume under extreme heat, it prevents the formation of secondary gaps through which fire and smoke could bypass the barrier.

2. Why Woqin is the Contractor’s Secret Weapon

For an EPC (Engineering, Procurement, and Construction) contractor, the ultimate nightmare is not the fire itself, but a failed site handover. If the fire marshal or the project consultant finds that the fire-stopping materials do not meet the specified ASTM or ISO standards, the resulting delays can cost millions in penalties.

Zero-Risk Audit Compliance We have designed our high-density slabs (120 kg/m³ - 160kg/m³) specifically to survive the most rigorous audits. Our products are fully compliant with ISO 834 (Fire Resistance Tests) and ASTM E814 (Standard Test Method for Fire Tests of Through-Penetration Firestops). When you specify Woqin, you are not just buying mineral wool; you are buying the peace of mind required for tough site handovers. Every shipment can be accompanied by batch-traceable test reports, ensuring that the material on your pallet matches the performance in the lab.

Zero Corrosion Guarantee: Protecting Your Assets A common hidden risk in low-grade mineral wool is its chemical composition. Many cheaper alternatives contain high levels of leachable chlorides. In the humid environments of cable tunnels, these chlorides can leach out and cause Stress Corrosion Cracking (SCC) or general pitting corrosion on the very assets you are trying to protect—the expensive galvanized cable trays and the polymer jackets of the cables themselves.

Woqin Rock Wool features a ultra-low chloride content, meeting the strict requirements of ASTM C795. We guarantee that our wool will not corrode your infrastructure, ensuring that while the fire is kept out, the internal systems remain pristine and reliable for their full intended service life.

3. Consistency from Factory to Site: The Bulk Advantage

Mega-projects, such as international airports, data centers, and oil refineries, operate on a scale where even small variations in material quality can lead to systemic risks.

The Power of Single-Line Production One of the greatest procurement risks in large-scale projects is "Mixed Batches"—sourcing from multiple small workshops to fill a large order. This leads to fluctuations in density, binder content, and fire resistance. At Hebei Woqin, we eliminate this risk. We ensure that every slab for your mega-project comes from the same production line under the same automated quality control standards. This consistency eliminates performance fluctuations and ensures that the 1,000th slab performs exactly like the first.

Optimizing Your Project Budget (Save 15%) In a competitive bidding environment, the project budget is always under pressure. By sourcing container-load shipments directly from our factory, EPC contractors can cut out multiple layers of middlemen, wholesalers, and local distributors. This direct-supply model typically results in a 15% reduction in total material costs. Furthermore, we provide logistics optimization, ensuring that the slabs are packed and sized to minimize on-site cutting and labor waste, further driving down the "Installed Cost" of the fire-stopping system.

4. Comparative Case Studies: Real-World Reliability

Case Study A: The Vertical Shaft in a High-Rise Data Center

- The Challenge: A Tier-4 data center required a 4-hour fire rating for vertical cable penetrations. Previous foam-based sealants had failed the integrity test due to "slumping" under heat.

- The Woqin Solution: Installation of 160kg/m³ high-density Rock Wool slabs with batch-traceable ASTM E814 certification.

- The Result: During the final fire inspection, the Woqin barrier maintained its structural position even under the pressure of fire hoses. The project achieved full certification on the first attempt, saving the contractor 3 weeks of potential rework.

Case Study B: The Industrial Power Tunnel for a Coastal Refinery

- The Challenge: A refinery needed to seal horizontal cable galleries that were exposed to high humidity and salt mist. The primary concern was preventing corrosion on stainless steel cable trays.

- The Woqin Solution: Bulk supply of low-chloride, hydrophobic-treated Rock Wool slabs.

- The Result: Five years post-installation, a routine maintenance audit confirmed that there was zero corrosion on the cable trays. The project manager noted that the consistency of the slabs (all from the same production batch) made the inspection process significantly faster and more predictable for the insurance auditors.

5. Take Action: Secure Your Tender and Your Timeline

Don’t let a fire-stop audit derail your project timeline or your reputation. In the world of high-stakes infrastructure, reliability is the only currency that matters.

Contact the Hebei Woqin industrial supply team today to:

- Request a bulk quote with factory-direct pricing for your next tender.

- Access our library of batch-traceable test reports (ISO/ASTM).

- Consult with our engineers on pre-cut sizes for standard cable tray configurations to reduce on-site labor.

Hebei Woqin: Engineering the Safety of Global Infrastructure.

Written by - Ruibin An

Industry Veteran with 13+ Years of Experience. Deeply rooted in the insulation industry for over 13 years, specializing in supply chain optimization and global market trends for Rock Wool and Aerogel materials.

LATEST NEWS

Precision-Cut Aerogel: The One-Day Solution for UK Retrofit Experts

2026-01-25

Zero-Risk Fire Safety: Bulk High-Density Rock Wool for Mega Power Infrastructure – A1 Rated & Container-Ready

2026-01-21

The "Performance Decay" Trap: Why Your Building’s R-Value is Lower Than You Think

2026-01-20

Beyond Support: Why 8.11 MPa HDPU is the New ISO Standard for Cryogenic Pipe Supports & Heavy Loads

2026-01-20

Stop Thermal Bridges at the Source: High-Strength PU Structural Thermal Breaks (600 kg/m³)

2026-01-19