Premium Industrial Pipe Insulation Shells | Rock Wool, Glass Wool & Aluminum Silicate Solutions

PRODUCT INTRODUCTION

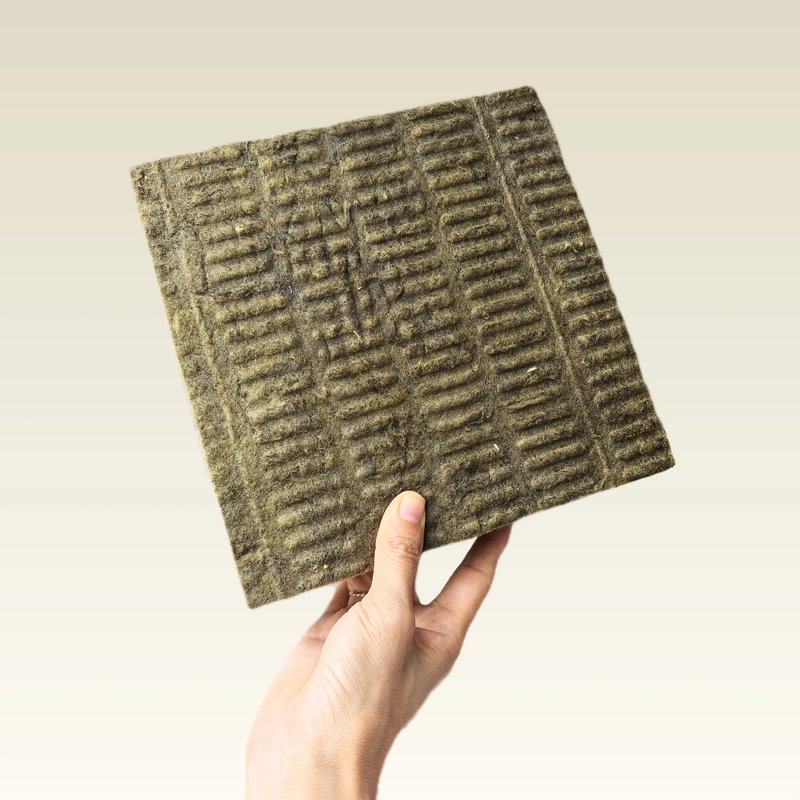

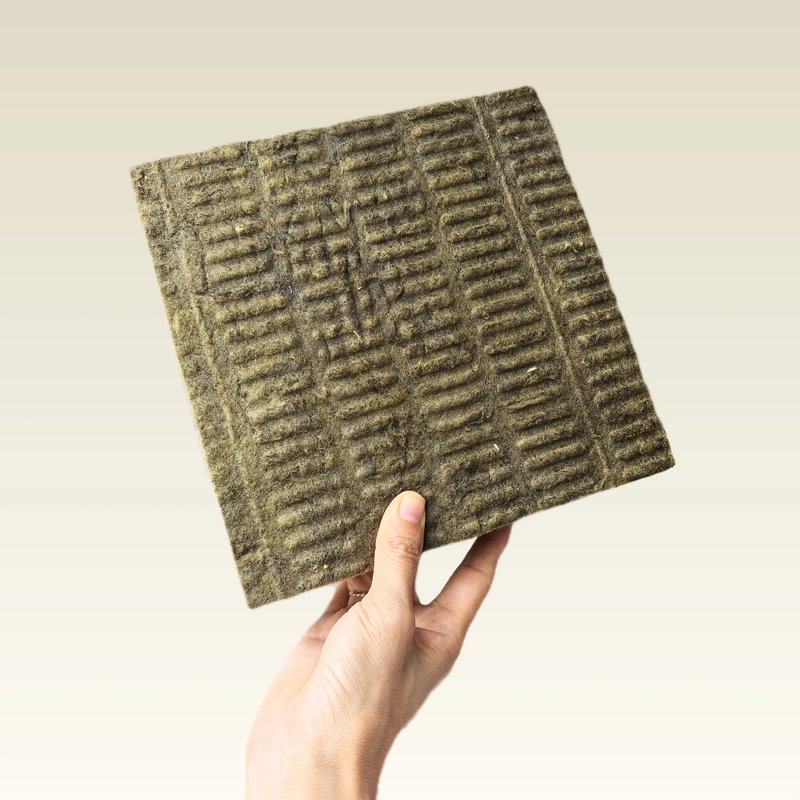

Hebei Woqin provides professional-grade pipe insulation shells with a "Triple-Core" system: Rock Wool, Glass Wool, and Aluminum Silicate. Covering temperatures from -268°C to 1000°C, our Class A1 fire-rated solutions feature 0.044 W/(m·K) conductivity and ≥98% hydrophobicity. Trusted in Dubai and Rotterdam for HVAC and petrochemical thermal protection.

| Category | Core Indicator/Parameter | Technical Index/Specification | Test Standard |

| Core Performance Indicators | Appearance | Flat surface (no use-affecting defects; no axial warpage) | GB/T 11835-2016 Appendix C |

| Key Dimensions & Allowable Deviation | Length: -2~+5mm; Inner Diameter: -3~+4mm; Thickness: -3~+5mm | GB/T 5480-2017 | |

| Thermal Conductivity (70℃) | ≤0.044 W/m·K | GB/T 10297-2015 | |

| Combustion Performance (Class A1) | Combustion Calorific Value ≤2.0 MJ/kg; Furnace Temp Rise ≤30℃; Sustained Burning Time = 0s | GB/T 11442-2007; GB/T 5464-2010 | |

| Hot Load Shrinkage Temperature | ≥600℃ | GB/T 11835-2016 Appendix E | |

| Key Component Limits | ω(Cl⁻)+ω(F⁻) ≤0.0112 (when ω(SiO₃²⁻)+ω(Na⁺)=0.0696) | JC/T 618-2019 | |

| Specification Parameters | Bulk Density | 80-150kg/m³ | Specification |

| Shell Inner Diameter | 18-610mm | Specification | |

| Shell Thickness | 30-200mm | Specification | |

| Shell Length | 1000mm | Specification |

Premium Industrial Pipe Insulation Shells (Triple-Core System)

Match the Core to the Stress:

"In industrial thermal protection, the core material must match the thermal stress of the environment," says Ruibin. We don't sell a single product; we offer a "Triple-Core" System. Whether you need standard steam protection or extreme furnace insulation, we provide the exact shell for your engineering requirement.

Key Technical Data (Certified Benchmark):

- Thermal Conductivity: ≤ 0.044 W/(m·K) (at 25°C) — High-efficiency heat retention.

- Service Temperature: Up to 1000°C+ (Depending on Core Selection).

- Corrosion Control: Low Chloride/Fluoride — Strictly meets JC/T 618-2019 to prevent pipe corrosion.

- Hydrophobic Rate: ≥ 98% — Excellent moisture resistance for outdoor pipelines.

- Fire Rating: Class A1 (Non-combustible).

- Dimensions: Inner Diameter 18mm - 610mm; Thickness 30mm - 200mm.

The "Triple-Core" Selection Guide:

- Glass Wool Core: Best for HVAC & Cooling/Heating (Up to 450°C).

- Rock Wool Core: The Standard for Steam & Boilers (Up to 650°C).

- Aluminum Silicate Core: For Extreme Metallurgy & Furnaces (Up to 1000°C+).

Why This Matters for Your Project:

- Zero Condensation: High hydrophobicity keeps pipes dry, critical for preventing CUI (Corrosion Under Insulation).

- Cost-Effective Alternative: If Aerogel is over budget, our High-Density Rock Wool is the preferred bulk alternative.

- Project Proven: Successfully deployed in Dubai Petrochemical Pipelines (300°C Steam), reducing surface temp to <50°C in high humidity.

💡 Ruibin's Tech Tip:

"Golden Rule: Do not over-compress during installation! A 15% reduction in thickness can degrade thermal performance by 15%. Just provide your pipe size (OD) and temperature, and my team will suggest the ideal density and core material within minutes."

[Button: Click Here to Get Factory Direct Quote]

Fast Quote

Get a price for Premium Industrial Pipe Insulation Shells | Rock Wool, Glass Wool & Aluminum Silicate Solutions

CONTACT US

RELATED PRODUCTS

NEW

High-Purity Ceramic Fiber Needle Blanket | 1260°C Grade Refractory Insulation

Professional grade alumina-silicate fiber...

Ultra-High Strength Graphite EPS Insulation Sub-frame | 2090 kPa Compression Resistance

Engineered for extreme structural integrity,...

Premium Rock Wool Insulation Boards | Factory Direct Bulk Supply (A1 Fireproof)

Manufactured from high-purity basalt ore using...

RELATED PRODUCTS

High-Purity Ceramic Fiber Needle Blanket | 1260°C Grade Refractory Insulation

Professional grade alumina-silicate fiber blanket verified by Lab Report ....

Ultra-High Strength Graphite EPS Insulation Sub-frame | 2090 kPa Compression Resistance

Engineered for extreme structural integrity, our Graphite EPS Sub-frame...

Premium Rock Wool Insulation Boards | Factory Direct Bulk Supply (A1 Fireproof)

Manufactured from high-purity basalt ore using our advanced low-slag...