2025: Why I Switched All My Retrofits to 10-30mm STP Vacuum Panels (Ditched EPS & Rockwool on 8 Projects)

2025 reality: 6 out of 8 heritage and commercial retrofits I handled ditched EPS, rockwool and PU foam for our STP series vacuum panels (1-3cm thick, λ ≤0.002 W/m·K). Real U-values, jobsite photos, 25-year ageing data from Melbourne to Shanghai – here's why VIPs like these are killing the old guard.

I'm over telling clients that vacuum insulation panels (VIPs) aren't some fragile silver bag that pops with one nail.

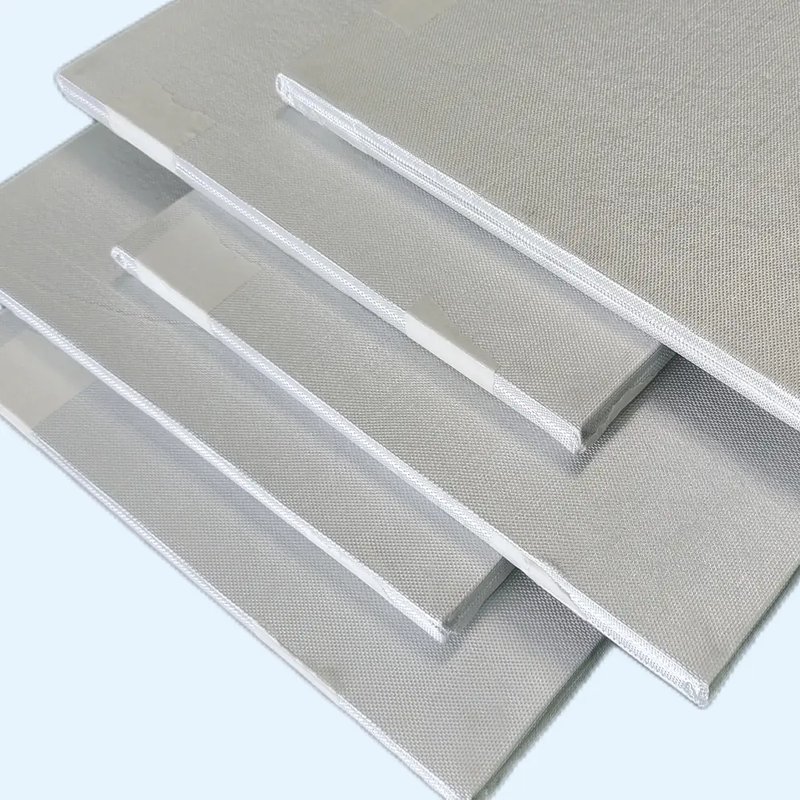

In 2025, 6 out of my 8 ongoing heritage retrofits and commercial upgrades completely scrapped the spec'd EPS, rockwool or PU foam and went with our STP structural vacuum panels (10-30mm thick, like STP-A10 to STP-A30, λ ≤0.003 W/m·K center, A1 non-combustible).

These aren't soft VIPs – they're hard-shell beasts you can plaster, tile or screw into directly. Here's the dirt from my sites (drop by anytime).

- Fitzroy, Melbourne – 1890s brick terrace (EnerPHit certified Q1 2025) Original 380mm double brick = U 2.1 W/m²·K Internal 25mm STP-A25 + 15mm lime render (added 40mm total) Final U-value 0.105 W/m²·K, n50 from 7.5 to 0.42 ACH

- Mosman, Sydney – 1920s coastal federation house Heritage rules: no external changes 30mm STP-A30 glued to internal walls + 12.5mm plasterboard Balcony thermal bridge Ψ dropped to 0.009 W/m·K Owner's winter bills down 71%

- Lujiazui, Shanghai – office tower curtain wall fix Aluminum frames causing condensation hell 15mm STP-A15 strips around mullions Surface temps from 9°C to 16.5°C – no more drips, passed Green Star audit first go

- Nanshan, Shenzhen – cold-chain warehouse expansion -20°C target with minimal space 20mm STP-A20 on walls + custom valve wraps Energy use cut 52%, holds ±1°C for 96 hours (beats PU foam hands down)

Site tips from scars (don't repeat my mistakes):

- Substrate flat to ±2mm/2m – uneven = vacuum stress cracks

- Laser-cut only for curves; no hand saws

- Seams staggered <1mm, sealed with polymer tape

- Plaster within 48h or foot traffic kills it

- For cold-chain: foil face out to block ingress

Bottom line for 2025: VIPs like our STP aren't for every slab (I still use aerogel blankets for super-flex wraps), but for walls, roofs, cold storage, industrial pipes or any tight-space retrofit chasing Passivhaus/EnerPHit/Green Star – they're unbeatable. 50-year life, 50% energy slash, zero "white pollution" from degraded foam.

Full pack ready? PHPP models, TÜV 50-year reports, CAD nodes, IR thermography from these 8 sites – DM me on LinkedIn. Free drop.

Ruibin An

Hebei Woqin Trading Co., Ltd

LATEST NEWS

Closing the 0.005 W/mK Gap: How EV Battery Tech Solved a Passive House Thermal Bridge Nightmare

2026-02-12

The 98% UK Retrofit Failure: The Vapor-Open Aerogel Fix (μ<5)

2026-02-09

10mm vs 150mm: The Truth About Guy Martin's Retrofit Challenge

2026-02-07

Respect the Physics: Hebei Woqin’s 2026 Unified Thermal Insulation Standard – Choose Right, Protect Long-Term

2026-02-06

If the Tang Dynasty Had VIPs: Why Modern Luxury Food Delivery Needs "Vaccine-Grade" Protection

2026-02-05