From Underdog to Carbon-Neutral Powerhouse: Aerogel's 2025–2030 Breakthrough and Strategic Opportunities

Early 2000s aerogel was dismissed as fragile and costly; by 2025, it has become a carbon-neutral powerhouse. With ultra-low conductivity (0.013–0.020 W/(m·K)), A1 fire resistance, and lightweight strength, aerogel slashes industrial energy loss (37% global CO₂) and enables EV battery safety. Market forecasts: 12–17% CAGR to 2030–2035; China dominates 97% capacity. Hebei Woqin scales blankets, particles, and coatings as your strategic supply partner for low-carbon transformation.

Aerogel's Underdog Triumph: From Abandoned Lab Material to Carbon-Neutral Linchpin

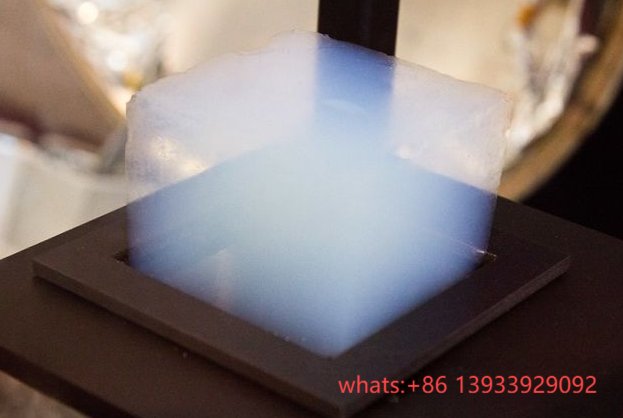

In the early 2000s, aerogel—dubbed "frozen smoke"—was dismissed as too fragile, costly, and impractical for mainstream construction. By 2025, this nanoscale marvel has surged to strategic status in high-stakes industries. Amid accelerating global carbon neutrality efforts, aerogel unlocks massive energy savings and emissions reductions, poised to capture a significant share of the industrial insulation market (projected $9–14 billion by 2030, with rapid penetration).

Aerogel's Superpowers: The Nanoscale Arsenal

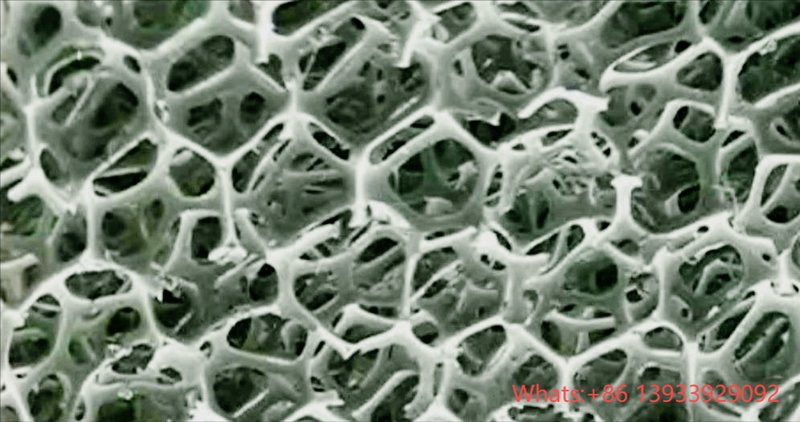

Aerogel's 3D nanoporous structure (20–50 nm pores) traps air in a silica/polymer skeleton, delivering game-changing properties:

- Insulation Mastery: Thermal conductivity 0.013–0.020 W/(m·K)—suppresses convection via Knudsen effect (molecules collide with walls).

- Featherweight Strength: Densities 3–200 kg/m³, supports 4,000× its weight.

- Flame & Corrosion Resistance: Withstands 650–1,200°C without melting/dripping; hydrophobic variants (contact angle >150°) prevent CUI.

- Green Credentials: Recyclable, non-toxic; increasingly from waste (rice husk ash, lignin) for circular economy.

These traits combat industrial energy loss (37% global CO₂ emissions). IDTechEx forecasts overall aerogel market CAGR 12.2% 2025–2035 (3.2× growth); Precedence Research projects $1.68B in 2025 → $6.54B by 2034 (CAGR 16.34%).

Conquering the "Impossible Triangle": Industrialization Breakthroughs

Early barriers—costs $1,000/kg, low yields, fragility—confined aerogel to labs. 2025 innovations have broken through:

- Supercritical Drying 2.0: Solvent recovery 95%, costs down 28%, throughput tripled (50,000 m³/line); Aspen halved cycles to 36 hours.

- Ambient-Pressure Optimization: Silane modifications enable room drying; fiber-reinforced composites gain 41% strength, energy use down 60% (Guangdong Alison exemplifies scale).

- Bio-Sourced Feedstocks: Rice husk/lignin cuts raw costs 33%; biodegradable variants emerge.

Prices have fallen to $100–200/kg (bulk), enabling mass adoption. EV battery insulation surges from $375M (2025) to $4.5B (2035, CAGR 28.3%).

Billion-Dollar Battlegrounds: High-Impact Applications

- New Energy Vehicles: Ultimate Fire Shield

Thermal runaway incidents (100+ in China 2024) demand inter-cell barriers. 0.5–1 mm aerogel blankets delay propagation (triple escape time). - Industrial Pipelines: Efficiency Rewrite

Oil/gas loses $10B yearly to heat escape. 15 mm aerogel felt replaces 50 mm rockwool, cutting loss 40%. - Aerospace: Nano-Armor

Extreme swings (−120°C to 1,200°C) demand flawless insulation. China's space station uses aerogel composites; Boeing 787 employs for 30 dB noise reduction.

The Cost Cascade: Democratization Drivers

Four forces drive affordability:

- Raw material plunge (silicone monomers ¥28,000/t).

- Equipment indigenization (domestic systems cut capex 60%).

- Recovery efficiency (35% savings).

- Scale effects (100,000 m³+ plants reduce costs 42%).

For 200 mm concrete walls: 10 mm aerogel vs 80 mm rockwool cuts costs 18%, boosts occupancy 2.3%.

China's Overtaking: Patents & Prowess

China holds 97% global capacity (IDTechEx 2025), with firms like Guangdong Alison and Namate leading exports to 50+ countries. Patents surge in hydrophobic, self-cleaning, and foldable films—setting next-gen standards.

At the Turning Point of Industrial Explosion—How Will You Position?

Aerogel's scale-up wave is here—not just technological iteration, but a reshaping of supply chains and strategic partnerships. Hebei Woqin doesn't just supply products (aerogel blankets: 0.020 W/(m·K), A1 fire-rated, 99.7% hydrophobic; particles 715.82 m²/g; coatings 0.032 W/(m·K))—we act as your strategic supply chain partner, offering:

- Feasibility analysis based on latest cost models to precisely evaluate project ROI.

- Deep technical solutions tailored to specific applications (EV, industrial pipelines, building energy efficiency).

- Long-term stable supply and co-development for mutual growth in the materials revolution.

Let's plan together how your next project wins from the starting line of this transformation.

Hebei Woqin Trading Co., Ltd.

Phone/WhatsApp/WeChat: +86 139 3392 9092

Email:an@cn-aerogel.com

Website: insulatewool.com

Written by - Zhongjian An

Certified Passive House Designer (PHI Germany), validated by Prof. Dr. Wolfgang Feist. With 15+ years of expertise in high-performance solutions for both Green Buildings and Industrial Applications (Petrochemical Pipelines, LNG Cryogenic, & High-Temp Equipment).

LATEST NEWS

Don't Be Fooled by Reflective Paints: Why Your Industrial Roof Gets Hot Again in Year Two

2026-02-19

Stop the Bulk: How to Choose the Right "Core" for Removable Insulation Jackets? (Aerogel vs. Rockwool Real-World Comparison)

2026-02-16

The "Great Squeeze" of 2026: Why Your 90-Day Terms Are Putting 25-Year Assets at Risk

2026-02-14

Closing the 0.005 W/mK Gap: How EV Battery Tech Solved a Passive House Thermal Bridge Nightmare

2026-02-12

The 98% UK Retrofit Failure: The Vapor-Open Aerogel Fix (μ<5)

2026-02-09