Aerogel Coats for Industrial Applications in 2025 and Beyond

The realm of industrial insulation is witnessing a revolutionary shift with the advent of aerogel coatings.

The realm of industrial insulation is witnessing a revolutionary shift with the advent of aerogel coatings. These ultra-lightweight materials, boasting remarkable thermal insulation properties, are redefining efficiency standards across various sectors. As the thermal insulation coating market expands, aerogel manufacturers are at the forefront, developing innovative solutions that promise to transform industrial processes. With their exceptional performance characteristics and versatile applications, aerogel coats are poised to become indispensable in industries ranging from petrochemicals to construction, offering unparalleled protection and energy savings.

Table of contents:

Exploring the Versatility of Aerogel Material in Various Industries

Enhancing Equipment Protection with Aerogel Thermal Insulation

The Cost Benefits of Implementing Aerogel Coats in Manufacturing

Future Trends in Industrial Insulation Using Aerogel Technology

Exploring the Versatility of Aerogel Material in Various Industries

The versatility of aerogel coatings has captured the attention of diverse industries seeking advanced thermal management solutions. Aerogel manufacturers have developed products that cater to a wide range of applications, from architectural insulation to industrial equipment protection. In the construction sector, these coatings are revolutionizing both interior and exterior insulation, providing superior moisture-proofing and temperature regulation. The thermal insulation coating market has seen a surge in demand for aerogel-based products in new energy battery insulation, showcasing the material's adaptability to emerging technologies. As industries continue to prioritize energy efficiency, the multifaceted applications of aerogel coatings are expected to expand further, driving innovation in the thermal insulation coating market.

Enhancing Equipment Protection with Aerogel Thermal Insulation

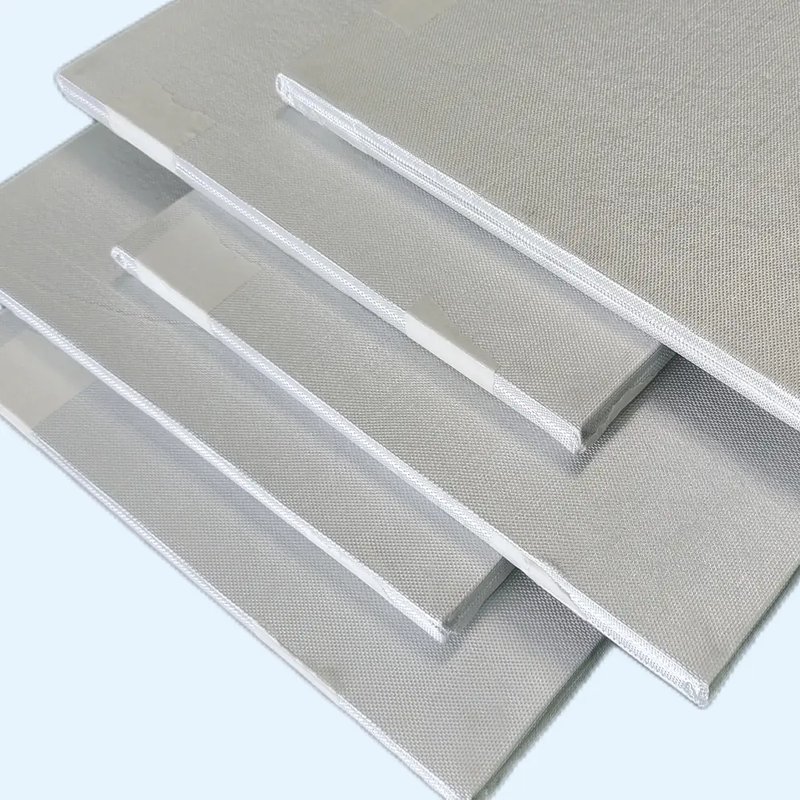

Aerogel coatings have emerged as a game-changer in equipment protection, offering unparalleled thermal insulation with minimal thickness. The nano-porous structure of aerogel, with pores ranging from 20 to 100 nanometers, creates an effective barrier against heat transfer. Aerogel manufacturers have harnessed this unique property to develop coatings that can withstand extreme temperatures, from -40°C to 800°C. This wide temperature range makes aerogel coats ideal for protecting industrial equipment in harsh environments. The thermal insulation coating market has seen significant growth in this sector, as companies recognize the long-term benefits of implementing aerogel solutions, including reduced energy consumption and extended equipment lifespan.

The Cost Benefits of Implementing Aerogel Coats in Manufacturing

While the initial investment in aerogel coatings may be higher than traditional insulation materials, the long-term cost benefits are substantial. Aerogel manufacturers have developed products that offer exceptional durability, with lifespans exceeding 20 years and resistance to UV degradation. This longevity, combined with the material's superior insulation properties, translates to significant energy savings over time. Case studies in the thermal insulation coating market have shown impressive results, such as a 60% decrease in summer energy consumption for petrochemical storage tanks treated with aerogel coats. The reduction in air conditioning usage by up to 50% in residential applications further demonstrates the economic advantages of aerogel technology. As manufacturing processes become more energy-conscious, the cost-effectiveness of aerogel coatings is likely to drive their widespread adoption.

Future Trends in Industrial Insulation Using Aerogel Technology

The future of industrial insulation is closely tied to advancements in aerogel technology. Aerogel manufacturers are continuously refining their products, focusing on enhancing performance while reducing production costs. The thermal insulation coating market is expected to see an influx of specialized aerogel coatings tailored for specific industrial applications. Innovations such as composite adhesive technologies and compliance with evolving national standards (like GB/T 35608-2024 and T/CECS 835) are setting new benchmarks for quality and efficiency. As environmental regulations become more stringent, the eco-friendly nature of aerogel coatings positions them as a sustainable choice for industries looking to reduce their carbon footprint. The integration of smart technologies with aerogel coatings, such as temperature-sensing and odor-purifying properties, hints at a future where insulation materials play an active role in environmental control and energy management.

The trajectory of aerogel coats in industrial applications is undeniably upward. As we look towards 2025 and beyond, the thermal insulation coating market is set to experience significant growth, driven by the innovative solutions offered by aerogel manufacturers. The combination of superior insulation performance, versatility across industries, and long-term cost benefits positions aerogel technology as a cornerstone of future industrial efficiency. With ongoing research and development, we can anticipate even more advanced applications and improved formulations, further cementing the role of aerogel coats in shaping a more energy-efficient and sustainable industrial landscape.

LATEST NEWS

Closing the 0.005 W/mK Gap: How EV Battery Tech Solved a Passive House Thermal Bridge Nightmare

2026-02-12

The 98% UK Retrofit Failure: The Vapor-Open Aerogel Fix (μ<5)

2026-02-09

10mm vs 150mm: The Truth About Guy Martin's Retrofit Challenge

2026-02-07

Respect the Physics: Hebei Woqin’s 2026 Unified Thermal Insulation Standard – Choose Right, Protect Long-Term

2026-02-06

If the Tang Dynasty Had VIPs: Why Modern Luxury Food Delivery Needs "Vaccine-Grade" Protection

2026-02-05