Tempered glass

PRODUCT INTRODUCTION

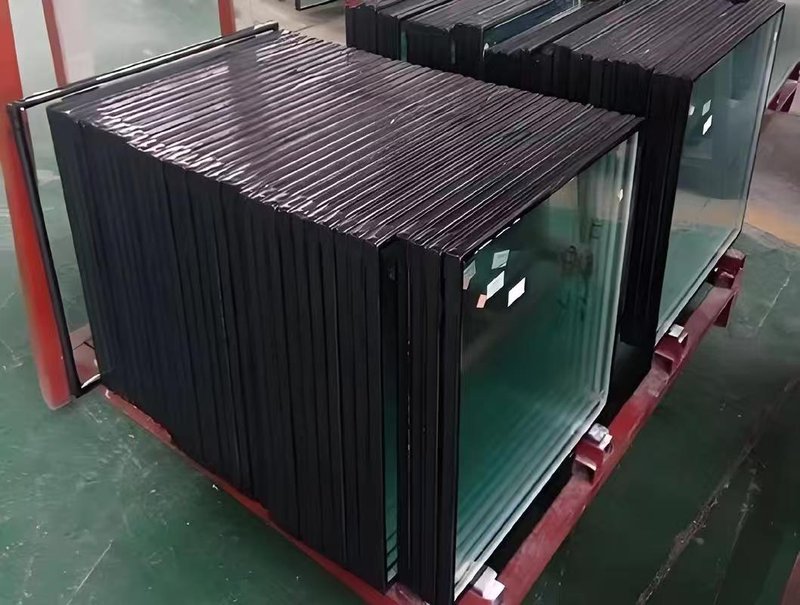

Tempered glass, also known as strengthened glass, is a type of safety glass made through a special heat treatment process. It is a kind of safety glass made through a special heat treatment process, with a strength 4 to 5 times that of ordinary glass and capable of withstanding temperature differences of over 200℃. When broken, tempered glass presents obtuse granular form, preventing the formation of sharp fragments and significantly enhancing safety

The strength of tempered glass lies in its ability to withstand pressure and its design concept is safety. This safety-grade material has undergone high-temperature strengthening treatment and is reliable whether in residential or commercial Spaces. Its strength is five times that of ordinary glass, it is impact-resistant, heat-resistant, and designed to be fragile without generating sharp fragments. It is highly suitable for areas with high foot traffic, damp areas, and structural applications. We can provide tempered glass of various shapes such as round, square, rectangular, oval, hexagonal, etc. You can also submit your own design drawings of tempered glass plates. And select the appropriate thickness (4-12mm) according to the strength and load-bearing requirements.

According to shape, it can be divided into flat tempered glass and curved tempered glass. According to the process, it can be divided into physical tempered glass and chemical tempered glass. According to the degree of tempering, it can be classified into tempered glass, semi-tempered glass and super-tempered glass, etc.

It is widely applied in the fields of architectural decoration such as high-rise building doors and Windows, glass curtain walls, indoor partition glass, and skylights, as well as in industries like automotive windshields, home appliance manufacturing, electronic instruments, furniture manufacturing, and daily products.